Stereo composite polylactic acid foam material for oil-water separation and preparation method thereof

A technology for composite polylactic acid and foam materials, applied in the field of stereocomposite polylactic acid foam materials and their preparation, and polylactic acid foam materials, can solve the problems of post-use treatment of unfavorable materials, difficulty in large-scale promotion, harsh preparation conditions, etc., and achieve Excellent hydrophobicity, improved physical and mechanical properties, and increased surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a stereocomplex polylactic acid foam material for oil-water separation, the preparation raw materials include the following components: L-polylactic acid, D-polylactic acid, organic solvent and poor solvent;

[0034] The mass ratio of each component is: L-polylactic acid (1-2.5%), D-polylactic acid (1-2.5%), poor solvent (3-6%) and good solvent (89-95%), of which L-polylactic acid The mass ratio to D-polylactic acid is 1:1.

[0035] The concrete steps of its preparation method are as follows:

[0036] Step 1, preparation: L-PLA and D-PLA were dried in a vacuum oven at 70°C for 12 h before the experiment;

[0037] Step 2, prepare the organic solution of polylactic acid: Weigh the same mass of L-polylactic acid and D-polylactic acid in 50mL of 1,4-dioxane, and heat and stir at 55°C and 300 r / min for 3 h ;

[0038] Step 3, prepare a ternary solution of polylactic acid, 1,4-dioxane and water: Slowly add a certain amount of deionized water to the ab...

Embodiment 1

[0043] In the preparation method of the stereocomplex polylactic acid foam material of this embodiment, the mass percentages of each component added are: 1.36% of L-polylactic acid, 1.36% of D-polylactic acid, 94.00% of dioxane, and 3.28% of deionized water ;

[0044] The performance detection of the polylactic acid foam that the present embodiment prepares:

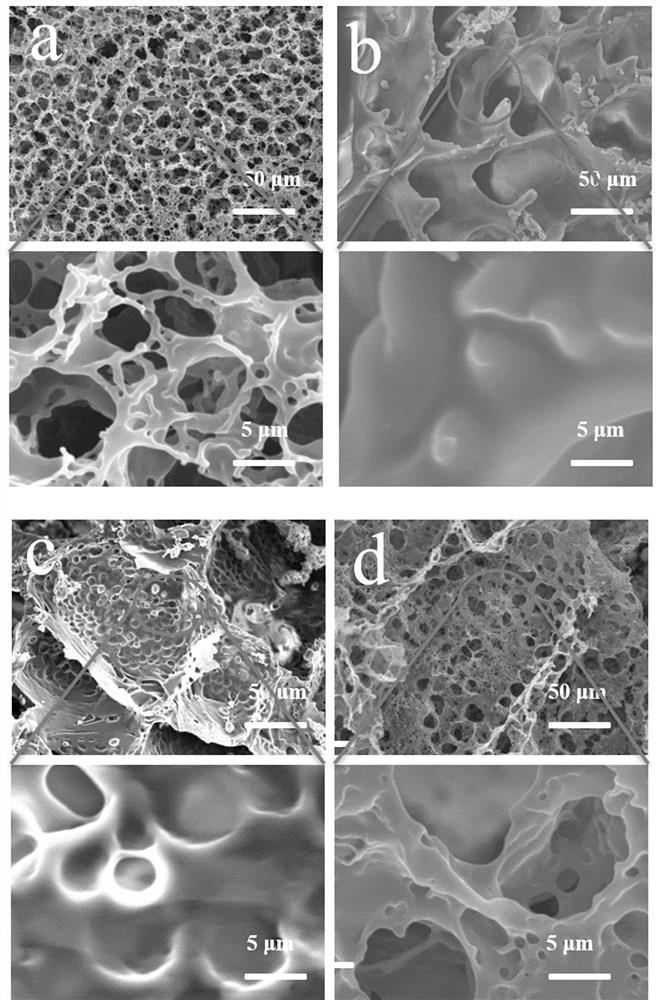

[0045] 1. Use a scanning electron microscope to observe the internal structure of the polylactic acid foam prepared in this embodiment, as figure 1 As shown in Figure a, the internal pores of the high-performance stereocomposite polylactic acid foam present a uniformly distributed micro-nano multi-level structure;

[0046] 2. Use cyclohexane, ethanol, carbon tetrachloride, pump oil and soybean oil to test the absorption capacity of the polylactic acid foam prepared in this embodiment to different types of oil stains, such as Figure 4 As shown in Figure a on the left; the mixed solution of cyclohexane and water dyed by S...

Embodiment 2

[0048] In the preparation method of the stereocomplex polylactic acid foam material of this embodiment, the mass percentage of each component is: 1.36% of L-polylactic acid, 1.36% of D-polylactic acid, 93.65% of dioxane, and 3.63% of deionized water;

[0049] The performance detection of the polylactic acid foam that the present embodiment prepares:

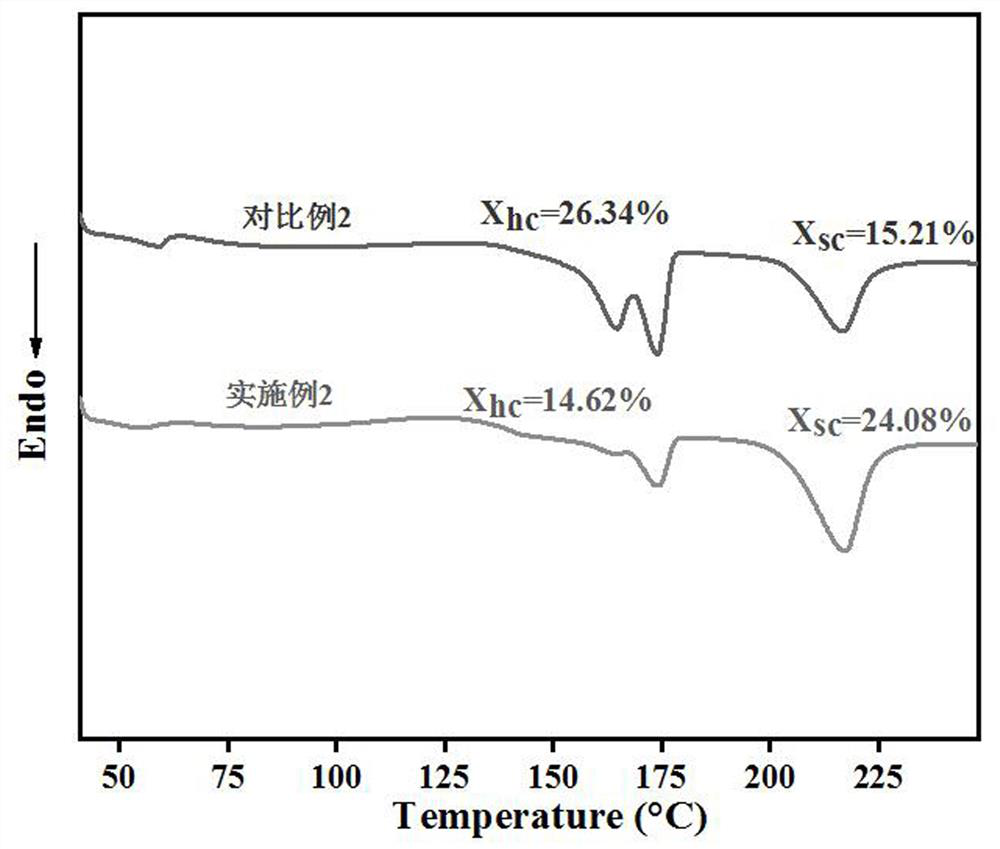

[0050] Adopt differential scanning calorimeter to observe the crystallization situation of the polylactic acid foam that present embodiment prepares, as figure 2 As shown, the high-performance stereocomplex PLA foam has higher SC crystallization and lower HC crystallization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com