Metal anti-oxidation treatment method

A treatment method and anti-oxidation technology, applied in the field of anti-oxidation of metal materials, can solve problems such as loss of metal protection, change of thickness and appearance of raw metal materials, safety accidents, etc. Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) The preparation concentration is 1wt% dilute sulfuric acid solution A and alkylamine solution B; the alkylamine solution B is to dissolve n-butylamine in dimethylformamide, and the concentration of n-butylamine is 15wt%;

[0030] 2) Dip the copper wire in dilute sulfuric acid solution A to remove the original oxide layer on the surface of the copper wire, and then use distilled water and ethanol to wash the metal in sequence;

[0031] 3) The copper wire treated in step 2) is quickly transferred to the alkylamine solution B, reacted at 120° C. for 4 hours, and finally the treated copper wire can be washed and dried.

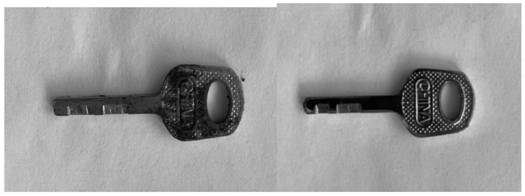

Embodiment 2

[0035] 1) Prepare the dilute acid hydrofluoric acid with a concentration of 1.8wt%, i.e. solution A;

[0036] 2) Immerse the nickel sheet in solution A for a certain period of time, the purpose is to remove the original oxide layer on the surface, and then wash it with distilled water and ethanol;

[0037] 3) dissolving octadecylamine in dimethylformamide, the concentration is 18wt%, namely solution B;

[0038] 4) Quickly transfer the treated nickel sheet to solution B, react at 95° C. for 7 hours, and dry to obtain a sample.

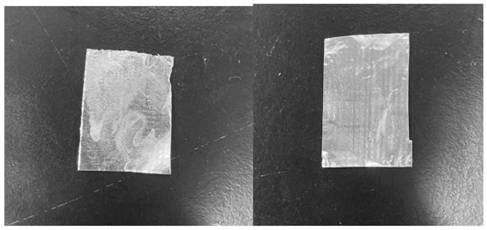

Embodiment 3

[0042] 1) The preparation concentration is 2wt% dilute acid oxalic acid, i.e. solution A;

[0043] 2) Immerse the tantalum sheet in solution A for a certain period of time, the purpose is to remove the original oxide layer on the surface, and then wash it with distilled water and ethanol;

[0044] 3) Dissolving triethylamine in dimethylformamide, the concentration is 20wt%, namely solution B;

[0045] 4) Quickly transfer the treated tantalum sheet to solution B, react at 115° C. for 10 h, and dry to obtain a sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com