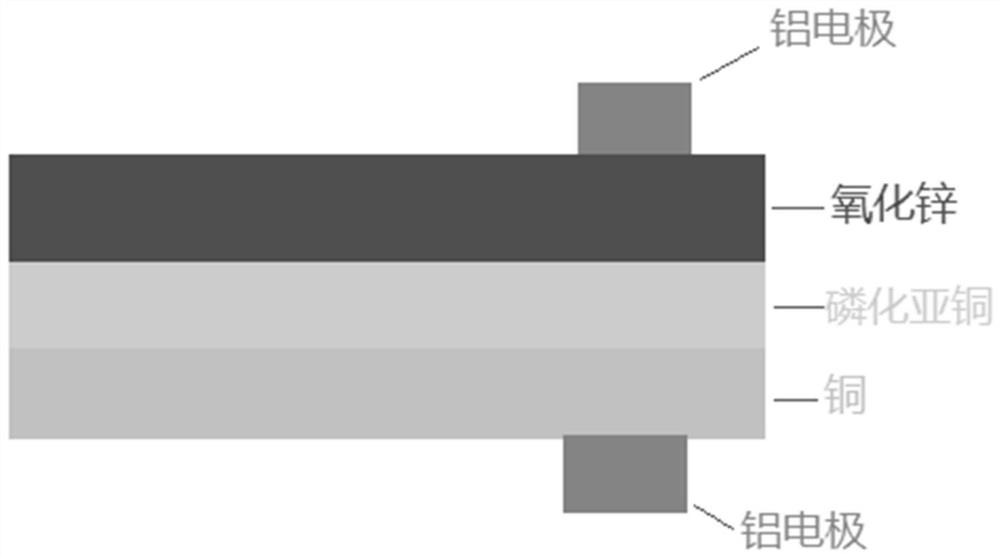

Preparation method of photoelectric detector based on zinc oxide-cuprous phosphide

A technology of photodetectors and cuprous phosphide, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as poor photoelectric effect, achieve low cost, high repeatability of device performance, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of preparation method based on zinc oxide-cuprous phosphide photodetector

[0018] Step (1). Sodium hypophosphite is put into the corundum boat, and then the surface of the corundum boat is covered with 1 square centimeter of copper foil with a thickness of 250 microns;

[0019] Step (2). Put the corundum boat in step (1) into the corundum tube. After vacuuming, fill it with argon gas of 1 atmosphere, and then seal the two ends of the corundum tube;

[0020] Step (3). Heat the corundum tube in step (2) to 280°C through a tube furnace at a heating rate of 10°C / min; keep warm after the temperature rises to 280°C for 30 minutes; then cool naturally to room temperature, pump the corundum tube Remove the residual gas in the tube by vacuum, and then take out the copper foil with cuprous phosphide grown on the surface of the product;

[0021] Step (4). Using the product of step (3) as a substrate, deposit an aluminum-doped zinc oxide film by magnetron sputtering; magne...

Embodiment 2

[0024] A kind of preparation method based on zinc oxide-cuprous phosphide photodetector

[0025] Step (1). Sodium hypophosphite is put into the corundum boat, and then the surface of the corundum boat is covered with 3 square centimeters of copper foil with a thickness of 500 microns;

[0026] Step (2). Put the corundum boat in step (1) into the corundum tube. After vacuuming, fill it with argon gas of 1 atmosphere, and then seal the two ends of the corundum tube;

[0027] Step (3). Heat the corundum tube in step (2) to 290°C through a tube furnace at a heating rate of 10°C / min; keep warm after the temperature rises to 290°C for 40 minutes; then cool naturally to room temperature, pump the corundum tube Remove the residual gas in the tube by vacuum, and then take out the copper foil with cuprous phosphide grown on the surface of the product;

[0028] Step (4). Using the product of step (3) as a substrate, deposit an aluminum-doped zinc oxide film by magnetron sputtering; magn...

Embodiment 3

[0031] A kind of preparation method based on zinc oxide-cuprous phosphide photodetector

[0032] Step (1). Sodium hypophosphite is put into the corundum boat, and then the surface of the corundum boat is covered with 5 square centimeters of copper foil with a thickness of 1000 microns;

[0033] Step (2). Put the corundum boat in step (1) into the corundum tube. After vacuuming, fill it with argon gas of 1 atmosphere, and then seal the two ends of the corundum tube;

[0034] Step (3). Heat the corundum tube in step (2) to 300°C through a tube furnace at a heating rate of 10°C / min; keep warm after the temperature rises to 300°C for 60 minutes; then cool naturally to room temperature, pump the corundum tube Remove the residual gas in the tube by vacuum, and then take out the copper foil with cuprous phosphide grown on the surface of the product;

[0035] Step (4). Using the product of step (3) as a substrate, deposit an aluminum-doped zinc oxide film by magnetron sputtering; mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com