Multivalent metal battery containing two-dimensional nanosheet additive

A two-dimensional nano, multivalent metal technology, applied in secondary batteries, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problem of losing control of metal deposition, and achieve high utilization of inhibiting the formation of loose and uneven metal deposition. , the effect of excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepared with 2.0mol L -1 ZnSO 4 , 0.5mg mL -1 The electrolyte solution of carbon nitride two-dimensional nanosheets uses water as a solvent and ultrasonically disperses at 25°C for 1 hour until the dispersion is uniform to form a colloidal electrolyte.

[0038] The electrolyte is used to use 100μm thick zinc metal foil as the negative electrode of the battery, and the surface capacity of the positive electrode is 1mAh cm -2 MnO 2 As the positive electrode, the glass fiber membrane is used as the diaphragm, and the constant current 1.0C is charged and discharged on the battery tester (Wuhan Landian Company), the Coulombic efficiency of the battery can reach 99.9%, and the cycle life is 1500 cycles.

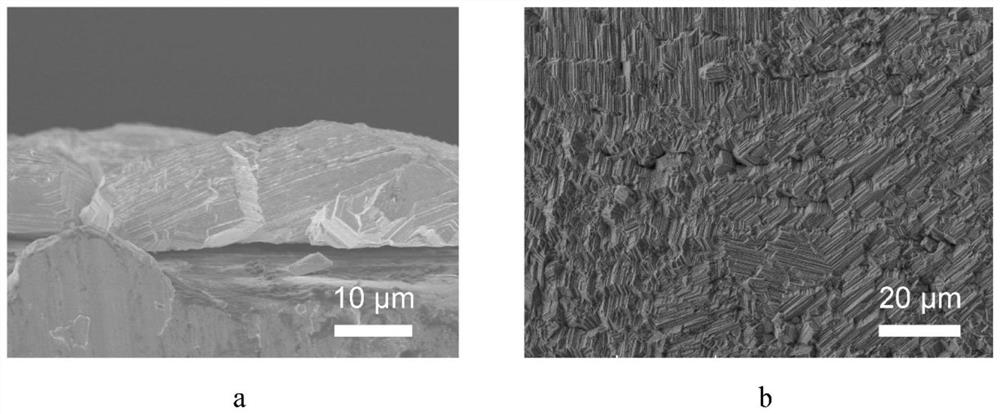

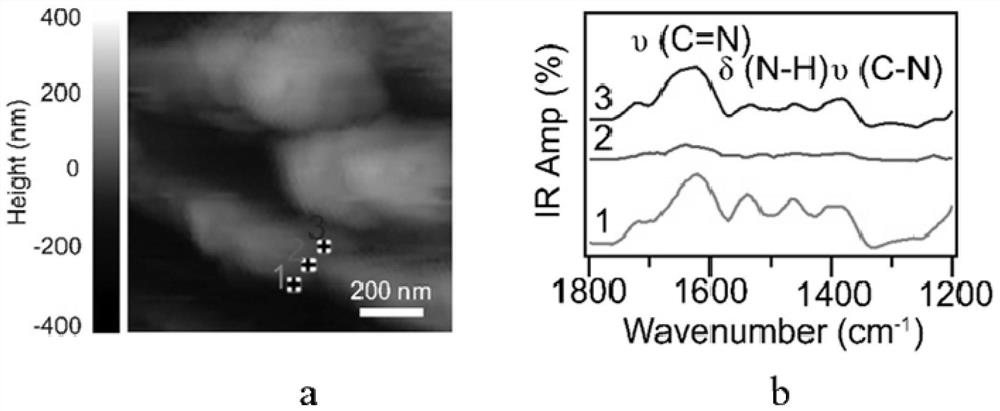

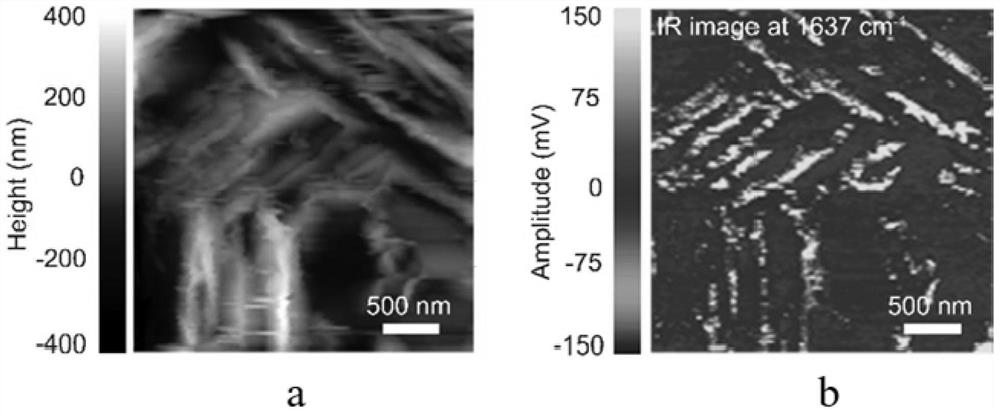

[0039] figure 1 It is the scanning electron microscope zinc metal deposition map of the first lap deposition in the electrolyte of this embodiment. It can be found from observation that the zinc metal deposition is dense and orderly arranged by using the electrolyte of ...

Embodiment 2

[0046] Prepared with 2.0mol L -1 ZnSO 4 , 1.0mg mL -1 The electrolyte solution of carbon nitride two-dimensional nanosheets uses water as a solvent and ultrasonically disperses at 0°C for 2 hours until the dispersion is uniform to form a colloidal electrolyte.

[0047] The electrolyte is used to use 20μm thick zinc metal foil as the negative electrode of the battery, and the surface capacity of the positive electrode is 6mAh cm -2 Zn x V 2 o 5 nH 2 O is the positive electrode, the glass fiber membrane is used as the diaphragm, and the constant current 1.0C is charged and discharged on the battery tester (Wuhan Landian Company), the Coulombic efficiency of the battery can reach 99.9%, and the cycle life is 400 cycles.

Embodiment 3

[0051] The preparation process is basically the same as that of Example 2, the only difference being that boron nitride two-dimensional nanosheets are added to the electrolyte.

[0052] The assembly and testing of the battery are exactly the same as those in Example 2. After testing, the Coulombic efficiency is 99.5%, the cycle life is 225 cycles, and the internal short circuit of the battery occurs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com