Detection robot based on rag type magneto-dependent sensor and fixed magnet yoke with gap

A magnetic sensor and fixed magnetic technology, applied in the field of detection robots, can solve problems such as the difficulty of ensuring the maximum gap of 0.5mm, the difficulty of post-cleaning, and the reduction of detection sensitivity, etc., to achieve fast detection speed, low missed detection rate, and no need for couplant Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to the accompanying drawings.

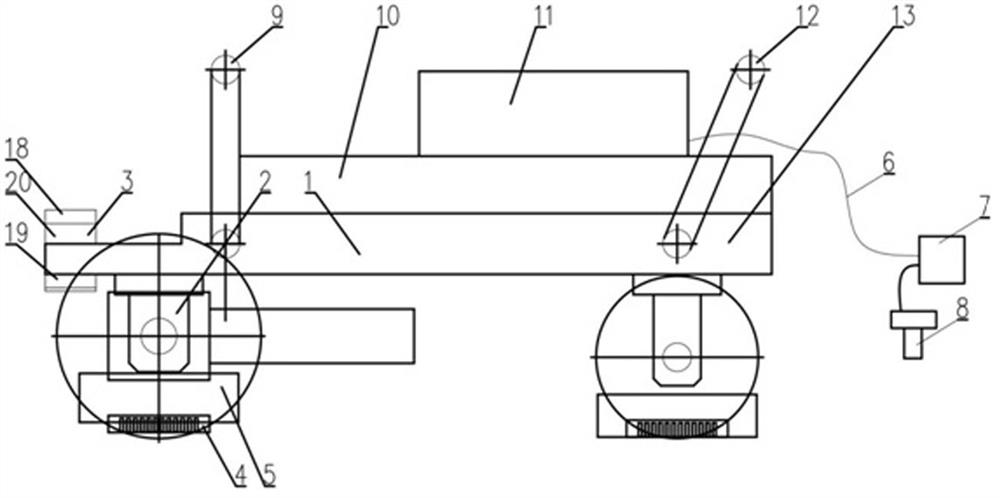

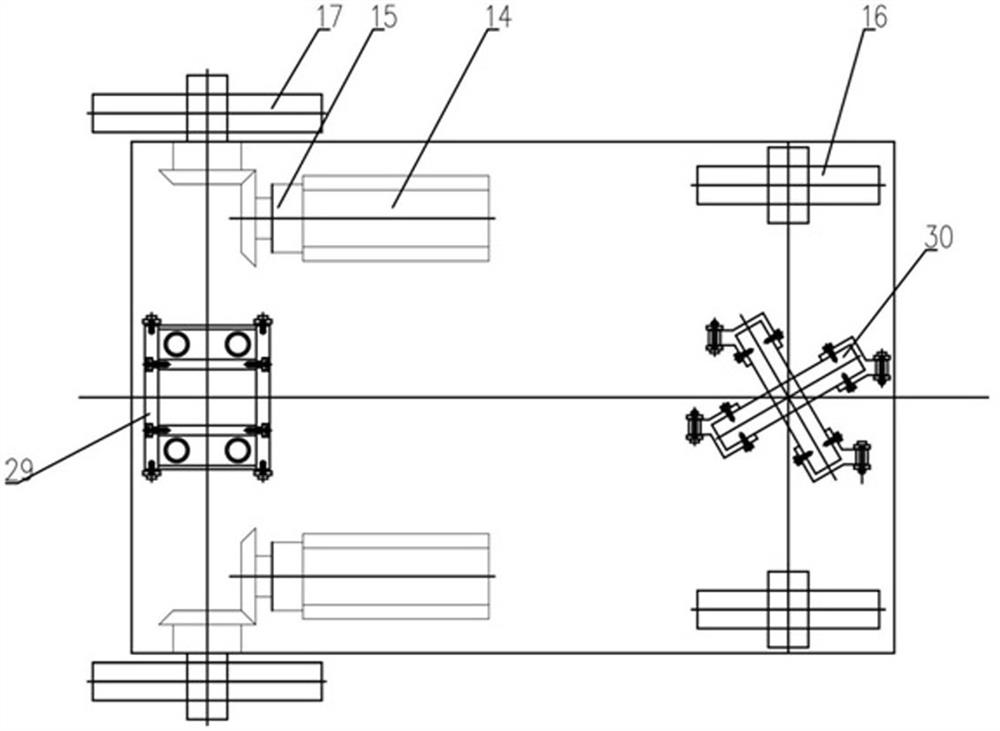

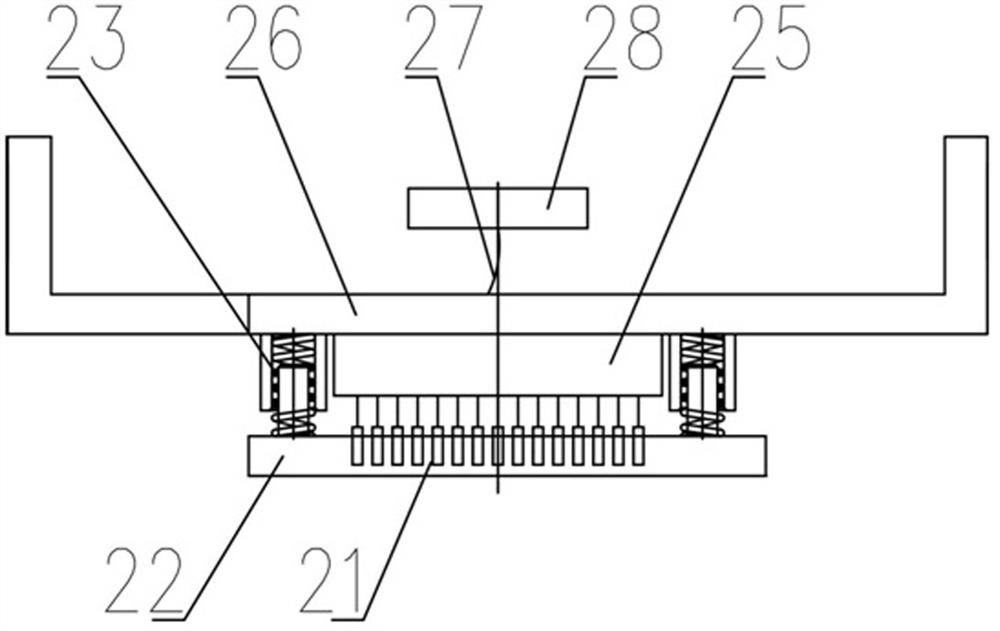

[0037] The technical scheme provided by the present invention is: as Figures 1 to 14 As shown, a detection robot based on a rag-type magnetic sensor and a fixed yoke with a gap, including an interconnected vehicle body 1, a drive system 2, a calibration and video detection system 3, a magnetic flux leakage and displacement detection system 4, The magnetization and adsorption system 5, the transmission cable 6, the ground station control box 7 and the automatic tracking pan-tilt 8 are composed.

[0038] Such as figure 1 As shown, the vehicle main body 1 includes a multifunctional lifting handle 9 , a housing 10 , a control box 11 , a rear handle 12 and a body bracket 13 . The multi-function hoisting handle can not only realize the hoisting function through the hoisting ring screw, but also realize different shapes by changing the position through the quick plug-in pin,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com