High-energy-storage and high-efficiency bismuth ferrite-strontium titanate ceramic and preparation method thereof

A high-efficiency, bismuth ferrite technology, applied in the field of relaxor ferroelectrics, can solve the problems of the second phase and sintering non-densification, and achieve the effect of reducing the steps of removing the binder, reducing defects, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

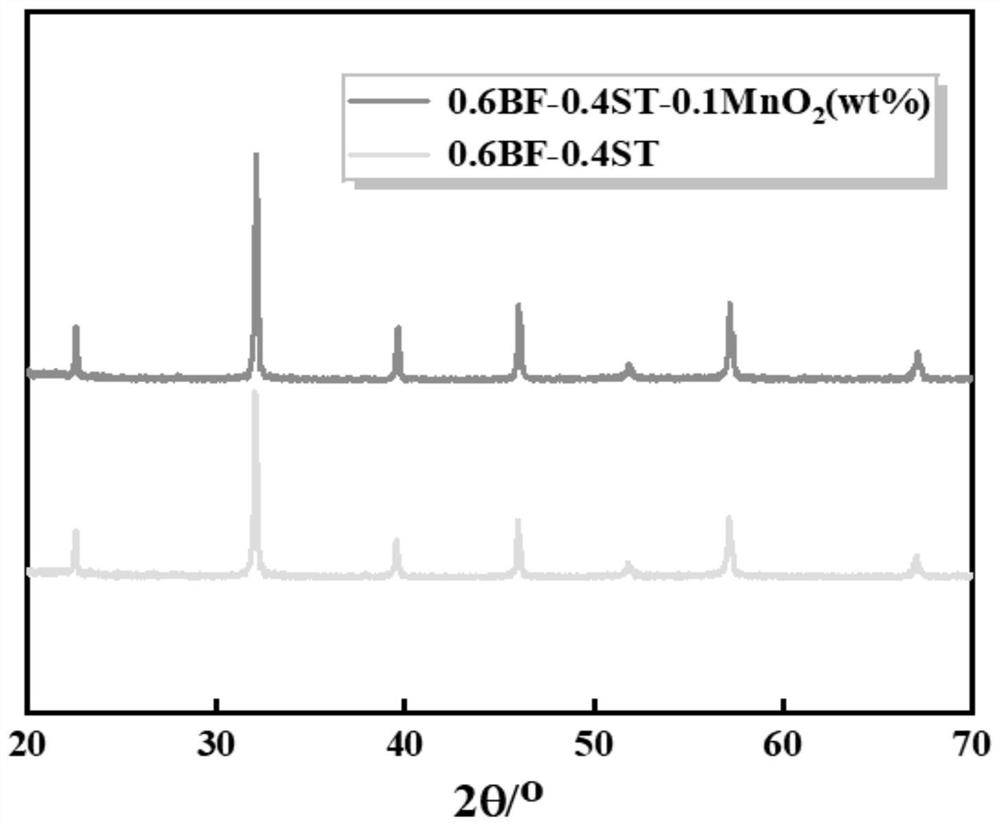

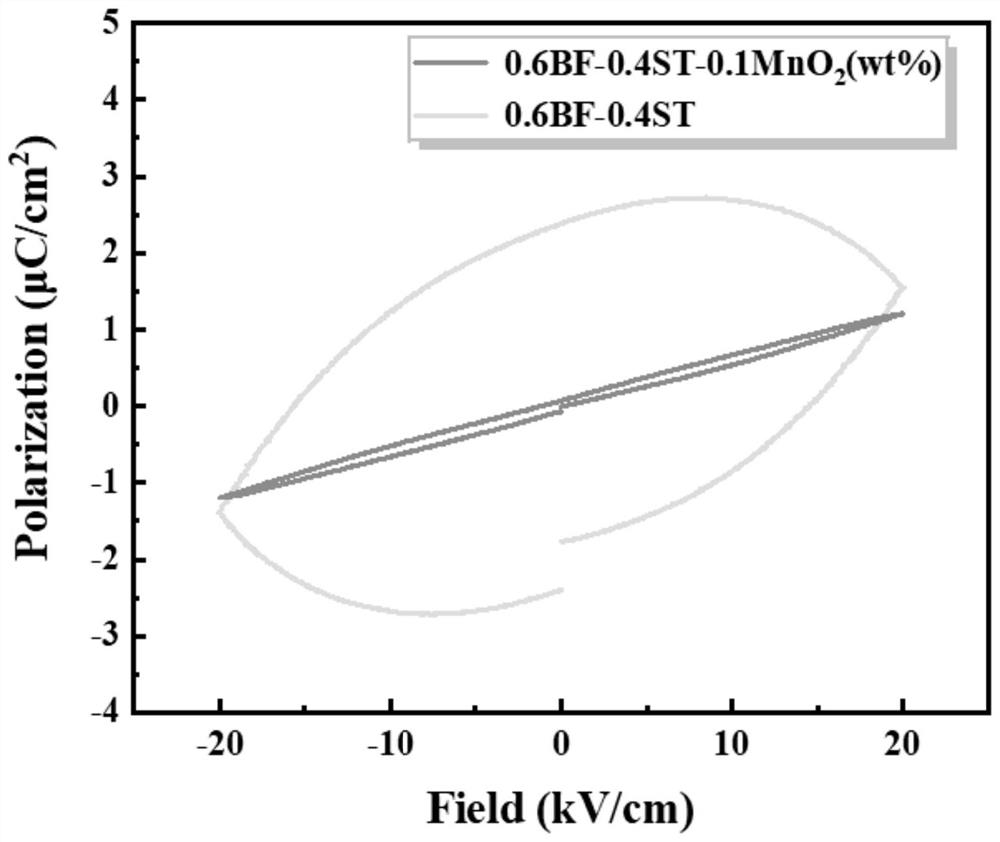

[0029] The chemical formula of the ceramic material is: 0.6BiFeO 3 -0.4SrTiO 3 -xwt%MnO 2 , where x represents the mass ratio, and x=0.

[0030] Above 0.6BiFeO 3 -0.4SrTiO 3 -0wt%MnO 2 A method for preparing a ceramic material, comprising the steps of:

[0031] (1) According to the chemical formula 0.6BiFeO 3 -0.4SrTiO 3 -0wt%MnO 2 Analytical pure Bi 2 o 3 , Fe 2 o 3 , SrCO 3 、TiO 2 and MnO 2 After preparation, among them, Bi 2 o 3 , Fe 2 o 3 , SrCO 3 with TiO 2 The molar ratio is: 1:1:1:1, MnO 2 The addition amount of is 0wt%. The mass ratio of raw materials, deionized water, and ball stones is 1:1:5, and the ball mill is mixed evenly for 12 hours, then dried at 80°C for 24 hours, and 0.6BiFeO with uniform size is obtained after passing through a 120-mesh sieve. 3 -0.4SrTiO 3 -0wt%MnO 2 Powder;

[0032] (2) 0.6BiFeO will be obtained 3 -0.4SrTiO 3 -0wt%MnO 2 The powder is poured into a mold with a diameter of 12mm and pressed into a mold, and the f...

Embodiment 2

[0037] The chemical formula of the ceramic material is: 0.6BiFeO 3 -0.4SrTiO 3 -xwt%MnO 2 , where x represents the mass ratio, and x=0.1.

[0038] Above 0.6BiFeO 3 -0.4SrTiO 3 -0.1wt%MnO 2 A method for preparing a ceramic material, comprising the steps of:

[0039] (1) According to the chemical formula 0.6BiFeO 3 -0.4SrTiO 3 -0.1wt%MnO 2 Analytical pure Bi 2 o 3 , Fe 2 o 3 , SrCO 3 、TiO 2 and MnO 2 After preparation, among them, Bi 2 o 3 , Fe 2 o 3 , SrCO 3 with TiO 2 The molar ratio is: 1:1:1:1, MnO 2 The added amount is 0.1wt%, and the mass ratio of raw materials, deionized water, and ball stones is 1:1:5, and the ball mill is mixed evenly for 12 hours, then dried at 80°C for 24 hours, and passed through a 120-mesh sieve to obtain a uniform size. 0.6BiFeO 3 -0.4SrTiO 3 -0.1wt%MnO 2 Powder;

[0040] (2) 0.6BiFeO will be obtained 3 -0.4SrTiO 3 -0.1wt%MnO 2 The powder is poured into a mold with a diameter of 12mm and pressed into a mold, and the for...

Embodiment 3

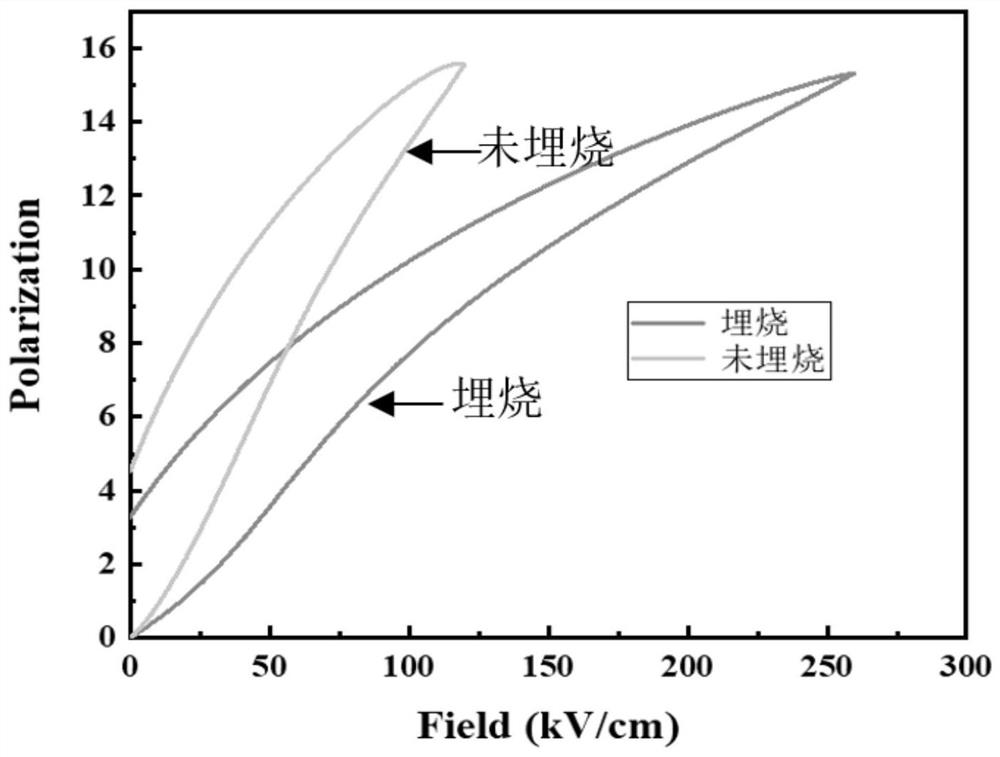

[0045] The chemical formula of the ceramic material is: 0.6BiFeO 3 -0.4SrTiO 3 -xwt%MnO 2 , where x represents the mass ratio, and x=0.1, and it has been buried and sintered during the sintering process.

[0046] Above 0.6BiFeO 3 -0.4SrTiO 3 -0.1wt%MnO 2 A method for preparing a ceramic material, comprising the steps of:

[0047] (1) According to the chemical formula 0.6BiFeO 3 -0.4SrTiO 3 -0.1wt%MnO 2 Analytical pure Bi 2 o 3 , Fe 2 o 3 , SrCO 3 、TiO 2 and MnO 2 After preparation, among them, Bi 2 o 3 , Fe 2 o 3 , SrCO 3 with TiO 2 The molar ratio is: 1:1:1:1, MnO 2 The added amount is 0.1wt%, and the mass ratio of raw materials, deionized water, and ball stones is 1:1:5, and the ball mill is mixed evenly for 12 hours, then dried at 80°C for 24 hours, and passed through a 120-mesh sieve to obtain a uniform size. 0.6BiFeO 3 -0.4SrTiO 3 -0.1wt%MnO 2 Powder;

[0048] (2) 0.6BiFeO will be obtained 3 -0.4SrTiO 3 -0.1wt%MnO 2 The powder is poured into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com