Solid electrolyte, preparation method of solid electrolyte, lithium ion battery and preparation method of lithium ion battery

A solid-state electrolyte and lithium-ion battery technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of insufficient lithium ion migration number and limit the development of polymer solid electrolytes, and achieve high migration number, Improved transport kinetics, cheap and readily available raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

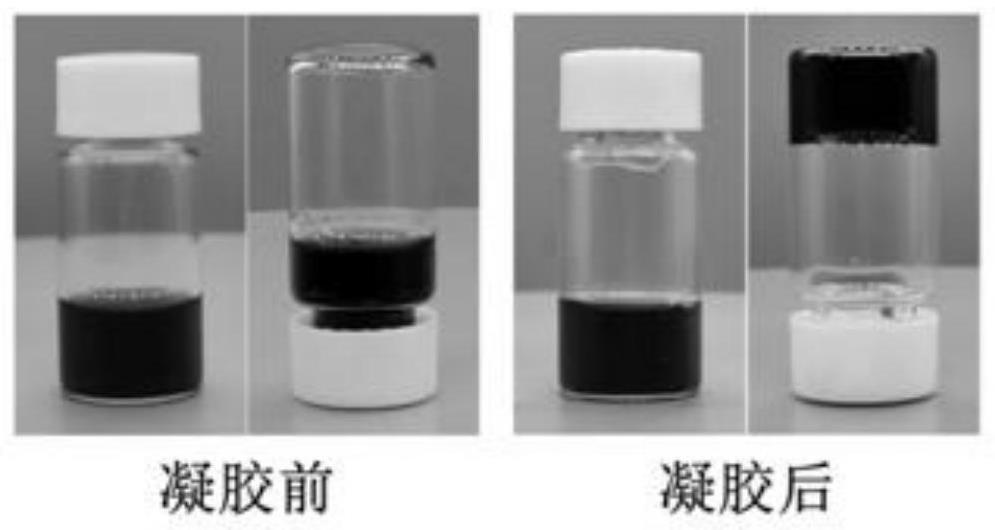

[0035] Under the condition of water and oxygen concentration less than 1ppm, dissolve lithium bistrifluoromethanesulfonate in 1,3-dioxolane at a molar concentration of 2mol / L, and then add 0.5% iodine and 2% ethyl Glycol dimethyl ether was stirred until it was completely dissolved to obtain a precursor liquid. The precursor solution was left standing at 25°C for 24h to obtain a polymer solid electrolyte (see figure 1 ), the ion conductivity at room temperature is 0.9mS / cm, and the transfer number is 0.85; the precursor solution is injected into the button battery or pouch battery assembled according to the positive electrode layer, diaphragm, and negative electrode layer, and static at 25°C Standing for 24 hours, a battery containing the polymer solid electrolyte was obtained.

Embodiment 2

[0037] Under the condition of water and oxygen concentration less than 1ppm, dissolve lithium bistrifluoromethanesulfonate at a molar concentration of 0.1mol / L in 1,4-epoxybutane, then add 0.1% iodine bromide by mass fraction, and stir until completely dissolved to obtain the precursor fluid. Put the precursor liquid at 0°C for 72 hours to obtain a polymer solid electrolyte with an ionic conductivity of 0.5mS / cm and a migration number of 0.76 at room temperature; inject the precursor liquid into the positive electrode layer, diaphragm, and negative electrode layer to assemble In the button battery or pouch battery, stand at 0°C for 72h to obtain a battery containing the polymer solid electrolyte.

Embodiment 3

[0039] Under the condition of water and oxygen concentration less than 1ppm, add lithium bistrifluoromethanesulfonate at a molar concentration of 6mol / L to 1,3-dioxolane, add 6% iodine trichloride by mass fraction, and stir until completely Dissolve, then add titanium dioxide with a mass fraction of 5%, and fully disperse to obtain a mixed solution. Let the mixed solution stand at 80°C for 4 hours to obtain a polymer solid electrolyte, which has an ion conductivity of 0.9mS / cm and a migration number of 0.83 at room temperature; inject the mixed solution into the positive electrode layer, diaphragm, and negative electrode layer. In a good button battery or a pouch battery, let it stand at 80°C for 4 hours to obtain a battery containing the polymer solid electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com