Ardealite flotation, washing, decolorizing and purifying method

A purification method and phosphogypsum technology, applied in flotation, solid separation, etc., can solve the problems of low utilization rate of phosphogypsum, reduce stockpiling and environmental pressure, have obvious effect, and be easy to decolorize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

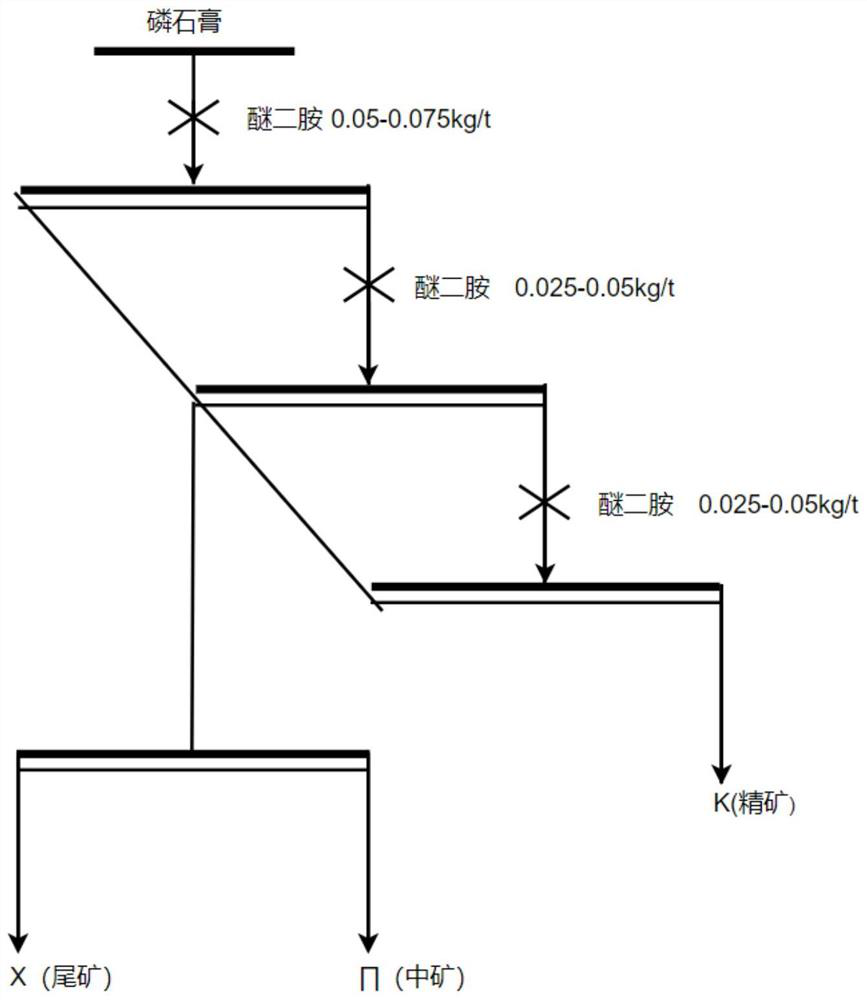

[0025] A phosphogypsum CaSO in Yunnan 4 2H 2 O content is 84.66%, phosphogypsum whiteness is 34.4%, SiO 2 The content of the content is 6.54%, carry out decolorization purification flotation process test, process flow chart sees figure 1 , including the following steps:

[0026] 1) Slurry the phosphogypsum to a reasonable mass concentration of 30%, perform the first reverse flotation, add the collector ether diamine (C10 ether diamine) at an amount of 0.05kg / t phosphogypsum, and carry out air flotation Until the foam is white, the reverse flotation foam remains, and the material remaining in the flotation tank continues the second reverse flotation. In the second reverse flotation, add collector ether diamine, the dosage is 0.025kg / t phosphogypsum, inflate flotation until the foam is white, the reverse flotation foam is retained, and the materials left in the flotation tank continue to Three reverse flotation. In the third reverse flotation, add collector ether diamine, t...

Embodiment 2

[0029] A phosphogypsum CaSO in Yunnan 4 2H 2 O content is 84.66%, phosphogypsum whiteness is 34.4%, SiO 2 The content of the content is 6.54%, carries out decolorization purification flotation process test, comprises the following steps:

[0030] 1) Slurry the phosphogypsum to 40% mass concentration, carry out the first reverse flotation, add the collector ether diamine (C12 ether diamine), the dosage is 0.06kg / t phosphogypsum, aerate the flotation to foam It is white, and the reverse flotation foam remains, and the material remaining in the flotation tank continues the second reverse flotation. In the second reverse flotation, add collector ether diamine, the dosage is 0.04kg / t phosphogypsum, inflate flotation until the foam is white, the reverse flotation foam is retained, and the materials left in the flotation tank continue to Three reverse flotation. In the third reverse flotation, add collector ether diamine, the dosage is 0.04kg / t phosphogypsum, inflate flotation un...

Embodiment 3

[0033] A phosphogypsum CaSO in Yunnan 4 2H 2 O content is 84.66%, phosphogypsum whiteness is 34.4%, SiO 2 The content of the content is 6.54%, carries out decolorization purification flotation process test, comprises the following steps:

[0034] 1) Slurry the phosphogypsum to 45% mass concentration, carry out the first reverse flotation, add the collector ether diamine (coco ether diamine) in an amount of 0.08kg / t phosphogypsum, and inflate the flotation to foam It is white, and the reverse flotation foam remains, and the material remaining in the flotation tank continues the second reverse flotation. In the second reverse flotation, add collector ether diamine, the dosage is 0.05kg / t phosphogypsum, inflate flotation until the foam is white, the reverse flotation foam is retained, and the materials left in the flotation tank continue to Three reverse flotation. In the third reverse flotation, add collector ether diamine, the dosage is 0.05kg / t phosphogypsum, inflate flota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com