Method for treating high-salt degradation-resistant wastewater by using closed bipolar electro-Fenton reactor

A Fenton reaction and wastewater technology, applied in chemical instruments and methods, water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as consumption, poor treatment effect of high-salt wastewater, quenching hydroxyl radicals, etc., to achieve Simple operation, low cost, and achieve the effect of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

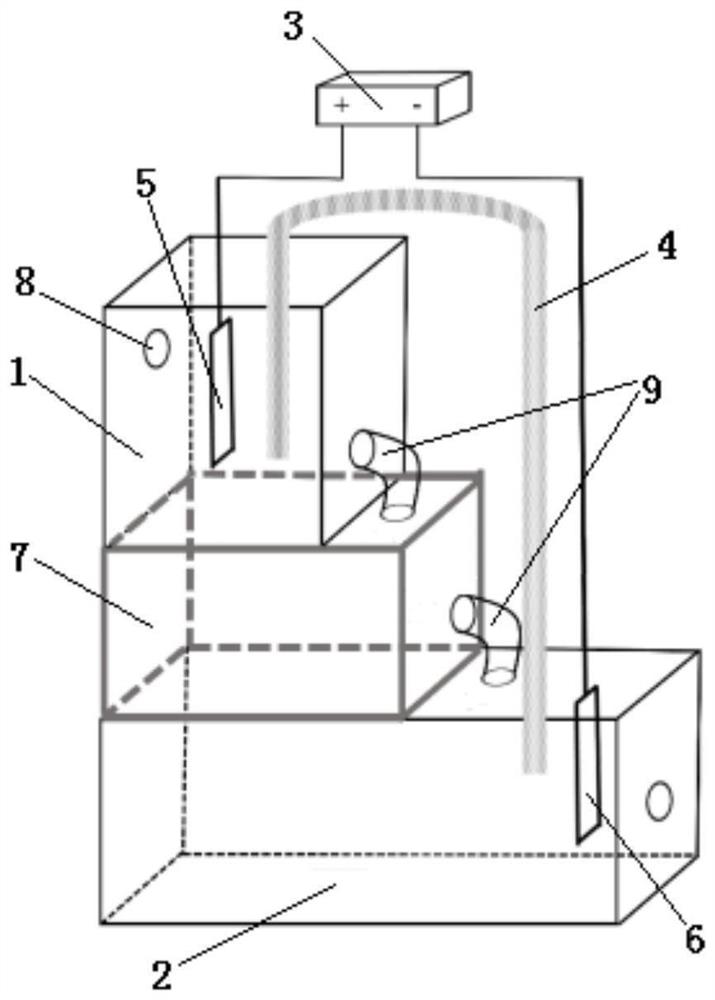

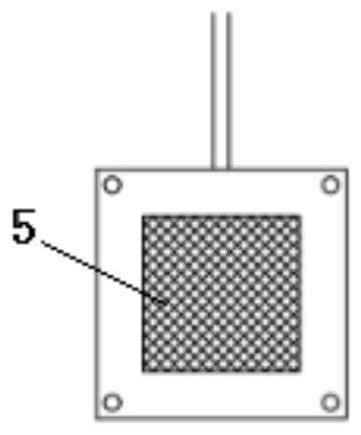

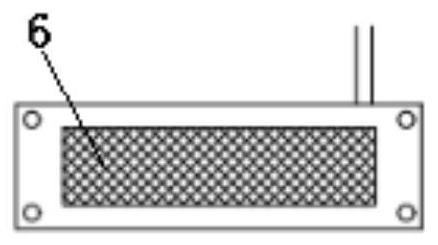

[0047] An electric Fenton reaction device, comprising an anode pool 1 and a cathode pool 2, the anode pool 1 is connected to the positive pole of a power supply 3 through an electrode, the cathode pool 2 is connected to the negative pole of the power supply 3 through an electrode, and the anode pool 1 and the cathode pool 2 are also connected through a conductive member 4 , by using the electrodes in the anode cell 1 and the cathode cell 2 as driving electrodes, and using the conductive member 4 as a common electrode, the anode cell 1 and the cathode cell 2 are independently subjected to an electric Fenton reaction.

[0048] The anode pool and the cathode pool are separately set up, and the anode pool is connected to the positive pole of the power supply through the electrodes, the cathode pool is connected to the negative pole of the power supply, and the anode pool and the cathode pool are also connected to the anode pool and the cathode pool through a conductive part, and the...

Embodiment 2

[0061] The method for treating high-salt wastewater using a conventional electric Fenton reaction device comprises the following steps: adjusting the pH value of the refractory high-salt wastewater to be treated to 3, adding 0.195g FeSO 4 Catalyst and 2.3ml hydrogen peroxide, turn on the DC power supply, and control the current density of the driving electrode of the conventional electric Fenton reaction device to be 5mA / cm 2 , for degradation reaction 2h.

[0062] In the present embodiment, the COD situation of the wastewater after the reaction is shown in the table below:

[0063] Table 1 embodiment 2 COD removal table

[0064]

Embodiment 3

[0065] Embodiment 3 adopts the method for treating high-salt wastewater by the closed double-cathode electric Fenton reaction device in embodiment 1, comprising the following steps:

[0066] 1) Adjust the pH value of the refractory high-salt wastewater to be treated to 3, add 0.08g Fe 2+ After the catalyzer, introduce in the anode cell of the closed electric Fenton reaction device, turn on the DC power supply, and control the current density of the driving electrodes in the anode cell and the cathode cell to be 5mA / cm 2 , carry out the degradation reaction;

[0067] 3) Discharge the wastewater in the anode pool, inject the wastewater in the adjustment pool into the cathode pool in turn, inject the wastewater in the anode pool into the adjustment pool, adjust the pH value of the untreated wastewater to 3, and add 0.08g FeSO 4 After the catalyst is injected into the cathode pool;

[0068] 4) Add 2.3mL of hydrogen peroxide to the cathode pool, turn on the power supply and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com