Treatment method of germanium thinning process processing wastewater

A technology for process processing and treatment methods, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

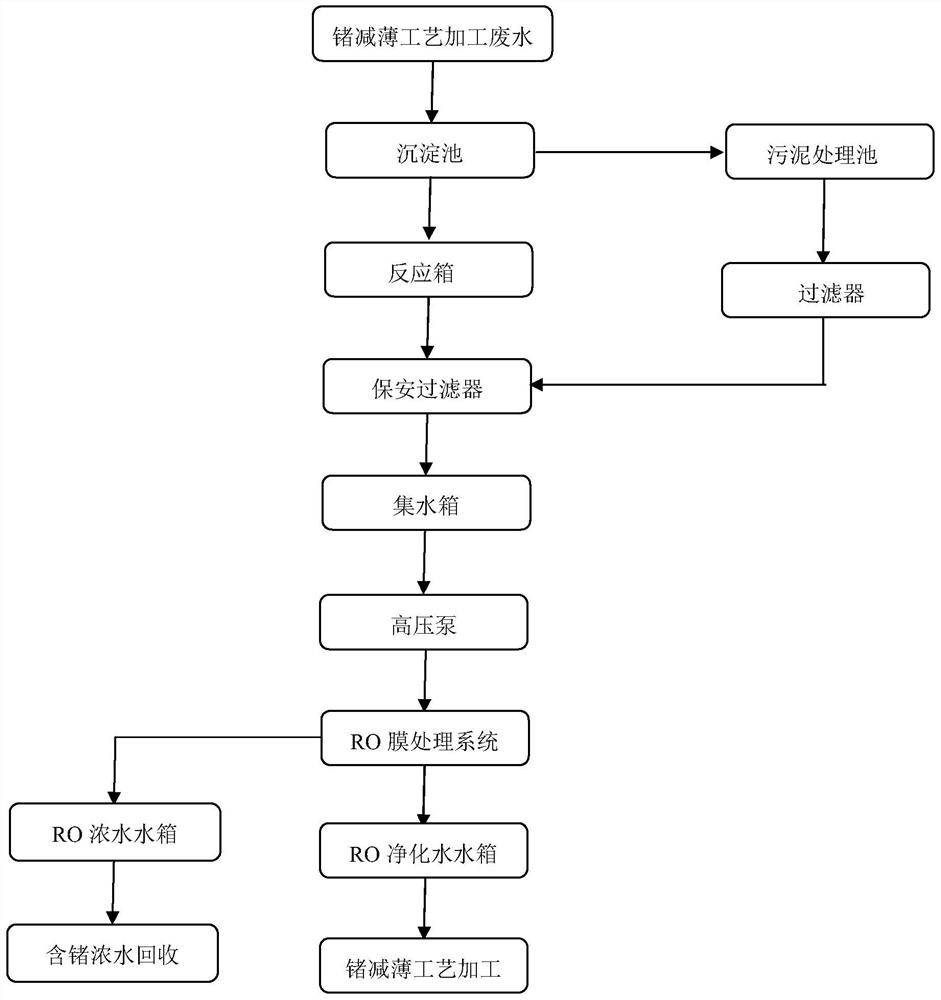

[0025] The treatment method of a kind of germanium thinning process processing waste water of the present embodiment, its process flow chart is as follows figure 1 As shown, it specifically includes the following processing steps:

[0026] (1) The germanium thinning process processing waste water flows into the sedimentation tank, and 4 mg / L polyferric sulfate is added in the sedimentation tank for coagulation and precipitation treatment;

[0027] (2) Step (1) The wastewater flowing out of the sedimentation tank flows into the reaction tank, and a mixed solution of sodium hydroxide and hydrogen peroxide with a mass ratio of 1:2.5 is added to the reaction tank for treatment; the sludge in the sedimentation tank enters the sludge treatment tank , feed 150mg / L ozone and 0.2wt.% sodium hydroxide solution into the sludge treatment tank for processing;

[0028] (3) The effluent treated in the reaction tank in step (2) passes through the security filter and then enters the water col...

Embodiment 2

[0031] The treatment method of a kind of germanium thinning process processing waste water of the present embodiment, its process flow chart is as follows figure 1 As shown, it specifically includes the following processing steps:

[0032] (1) The germanium thinning process processing waste water flows into the sedimentation tank, and 2 mg / L polyferric chloride is added in the sedimentation tank for coagulation and sedimentation treatment;

[0033] (2) Step (1) The wastewater flowing out of the sedimentation tank flows into the reaction tank, and a mixed solution of potassium hydroxide and hydrogen peroxide with a mass ratio of 1:2 is added to the reaction tank for treatment; the sludge in the sedimentation tank enters the sludge treatment tank , feed 100mg / L ozone and 0.1wt.% potassium hydroxide solution into the sludge treatment tank for processing;

[0034] (3) The effluent treated in the reaction tank in step (2) passes through the security filter and then enters the wate...

Embodiment 3

[0037] The treatment method of a kind of germanium thinning process processing waste water of the present embodiment, its process flow chart is as follows figure 1 As shown, it specifically includes the following processing steps:

[0038] (1) The germanium thinning process processing waste water flows into the sedimentation tank, and 6 mg / L polyphosphorus ferric chloride is added in the sedimentation tank for coagulation and precipitation treatment;

[0039] (2) Step (1) The wastewater flowing out of the sedimentation tank flows into the reaction tank, and a mixed solution of calcium hydroxide and hydrogen peroxide with a mass ratio of 1:3 is added to the reaction tank for treatment; the sludge in the sedimentation tank enters the sludge treatment tank , feed 230mg / L ozone and 0.3wt.% calcium hydroxide solution into the sludge treatment tank for processing;

[0040] (3) The effluent treated in the reaction tank in step (2) passes through the security filter and then enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com