Method for preparing mesoporous barium zirconate titanate ceramic nanoparticles

A barium zirconate titanate and nanoparticle technology, applied in the direction of nanotechnology, can solve the problems of unfavorable device miniaturization and easy breakdown, and achieve the effect of simple repeatability, low cost, and promotion of commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

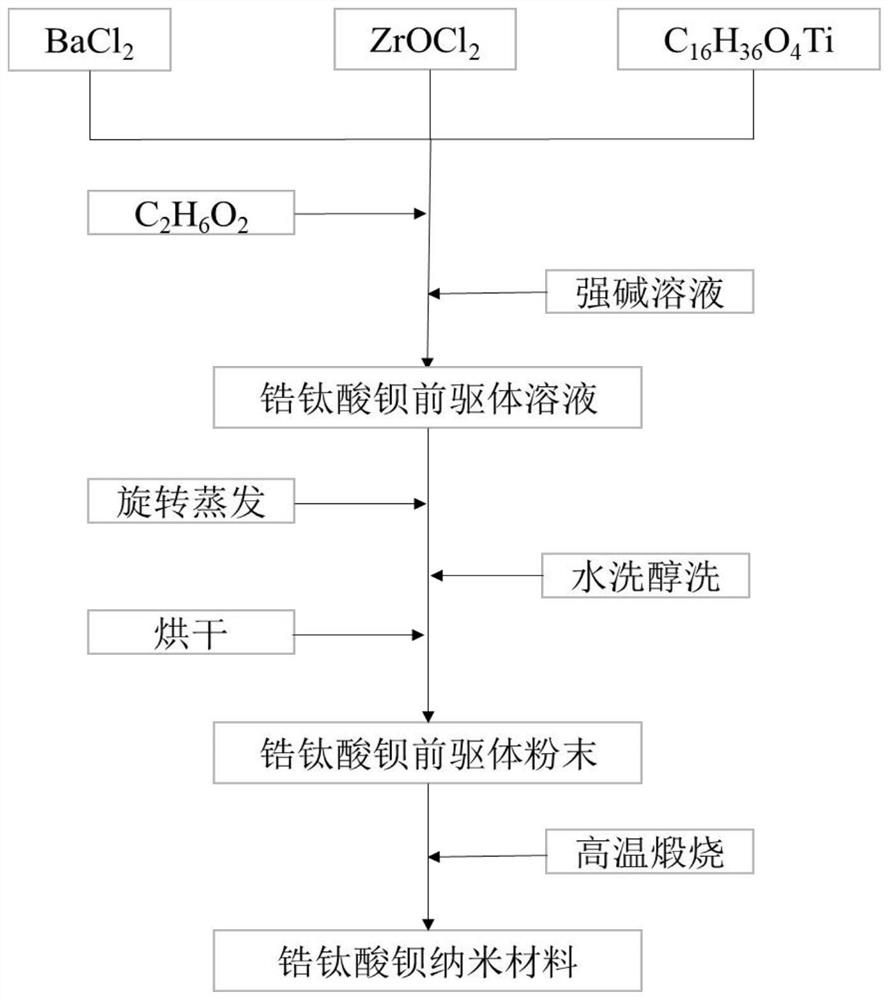

Method used

Image

Examples

Embodiment 1

[0034] Step 1, prepare ethylene glycol solution: weigh 0.776g C 2 h 6 o 2 Add 20mL deionized water to the beaker, and stir for 10min with a magnetic stirrer to obtain an ethylene glycol solution;

[0035] Step 2, prepare mixed solution: weigh 6.137g BaCl 2 Add 20mL deionized water into the beaker, stir for 10min with a magnetic stirrer, and weigh 4.279g ZrOCl 2 , using a magnetic stirrer to stir for 10 minutes to obtain a mixed solution;

[0036] Step 3, prepare titanium salt solution: measure 4.25mL C 16 h 36 o 4Put Ti in a beaker and add 10mL of absolute ethanol, and stir for 10min with a magnetic stirrer to obtain a titanium salt solution;

[0037] Step 4, preparing an alkaline solution: Weigh 12.5g of NaOH powder, add the weighed NaOH powder to 20mL deionized water in 5 times, and stir for 10min with a magnetic stirrer to obtain an alkaline solution;

[0038] Step 5, preparing the precursor solution: add the mixed solution obtained in step 2, the titanium salt solu...

Embodiment 2

[0042] Step 1, prepare ethylene glycol solution: weigh 1.552g C 2 h 6 o 2 Add 20mL deionized water to the beaker, and stir for 10min with a magnetic stirrer to obtain an ethylene glycol solution;

[0043] Step 2, prepare mixed solution: weigh 12.275g BaCl 2 Add 40mL deionized water into the beaker, stir for 20min with a magnetic stirrer, and weigh 8.557g ZrOCl 2 , using a magnetic stirrer to stir for 20 minutes to obtain a mixed solution;

[0044] Step 3, prepare titanium salt solution: measure 8.5mL C 16 h 36 o 4 Put Ti into a beaker and add 10mL of absolute ethanol, and stir for 20min with a magnetic stirrer to obtain a titanium salt solution;

[0045] Step 4, preparing an alkaline solution: Weigh 25g of NaOH powder, add the weighed NaOH powder into 40mL deionized water in 8 times, and stir for 20min with a magnetic stirrer to obtain an alkaline solution;

[0046] Step 5, preparing the precursor solution: add the mixed solution obtained in step 2, the titanium salt s...

Embodiment 3

[0050] Step 1, prepare ethylene glycol solution: weigh 3.104g C 2 h 6 o 2 Add 20mL deionized water to the beaker, and stir for 10min with a magnetic stirrer to obtain an ethylene glycol solution;

[0051] Step 2, prepare mixed solution: weigh 24.549g BaCl 2 Add 80mL deionized water to the beaker, stir for 30min with a magnetic stirrer, and weigh 17.114g ZrOCl 2 , using a magnetic stirrer to stir for 30 minutes to obtain a mixed solution;

[0052] Step 3, prepare titanium salt solution: measure 17mL C 16 h 36 o 4 Put Ti in a beaker and add 10mL of absolute ethanol, and stir for 30min with a magnetic stirrer to obtain a titanium salt solution;

[0053] Step 4, preparing an alkaline solution: Weigh 50g of NaOH powder, add the weighed NaOH powder into 80mL deionized water 10 times, and stir for 30min with a magnetic stirrer to obtain an alkaline solution;

[0054] Step 5, preparing the precursor solution: add the mixed solution obtained in step 2, the titanium salt solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com