PA color fixing agent and preparation method thereof

A color-fixing agent and curing agent technology, applied in the field of applied chemistry, to achieve the effect of simple process, stable and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

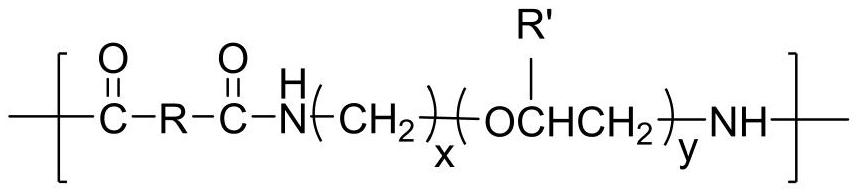

[0029] A kind of PA fixing agent provided by the invention, its structural formula is:

[0030]

[0031] Where: x=2, y=45

[0032] The preparation of the color fixing agent comprises the following steps in turn,

[0033] 1) Add 2.92g of adipic acid into a 100ml four-necked flask (with nitrogen protection, thermometer and vacuum equipment); then add 48g of ED2003 (Huntsman) into the four-necked flask;

[0034] 2) Seal the four-necked flask, raise the temperature to 180°C, and turn on the vacuum pump for vacuum dehydration at the same time;

[0035] 3) react for 8 hours, stop heating;

[0036] 4) When the temperature drops to about 70°C, stop the vacuuming, add 0.56g of acetic acid (98%) into the four-necked flask, and discharge the material to obtain a brown-yellow viscous liquid

Embodiment 2

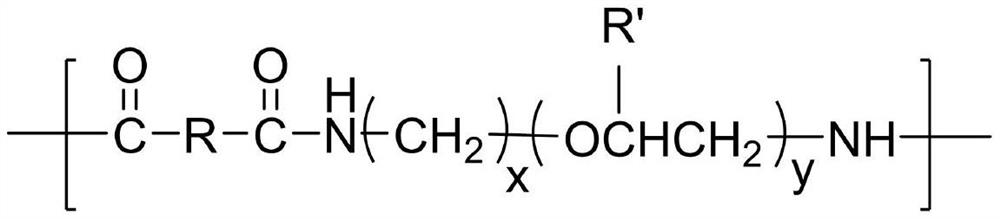

[0038] A kind of PA fixing agent provided by the invention, its structural formula is:

[0039]

[0040] Where: x=3, y=13

[0041] The preparation of the color fixing agent comprises the following steps in turn,

[0042] 1) Add 7.3g of adipic acid into a 100ml four-necked flask (with nitrogen protection, thermometer and vacuum equipment), and then add 36g of ED600 (Huntsman) into the four-necked flask;

[0043] 2) Seal the four-necked flask, raise the temperature to 180°C, and turn on the vacuum pump for vacuum dehydration at the same time;

[0044] 3) react for 4 hours, stop heating;

[0045] 4) When the temperature drops to about 70°C, stop vacuuming, add 1.45g of acetic acid (98%) into the four-necked flask, and discharge to obtain a light yellow viscous liquid

Embodiment 3

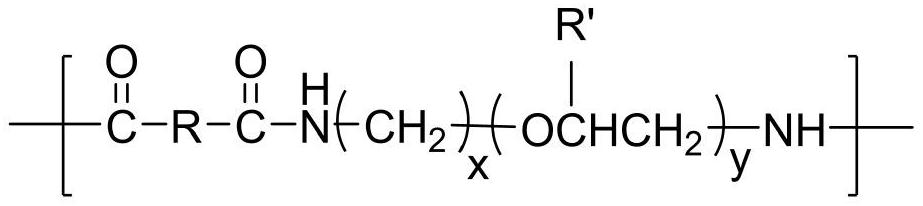

[0047] A kind of PA fixing agent provided by the invention, its structural formula is:

[0048] Where: x=4, y=78

[0049] The preparation of the color fixing agent comprises the following steps in turn,

[0050] 1) Add 2.75g of adipic acid into a 100ml four-necked flask (with nitrogen protection, thermometer and vacuum equipment), and add 20g of ED2003 and 20g of D2000 (Huntsman) into the four-necked flask;

[0051] 2) Seal the four-necked flask, raise the temperature to 180°C, and turn on the vacuum pump for vacuum dehydration at the same time;

[0052] 3) react for 12 hours, stop heating;

[0053] 4) When the temperature drops to about 70°C, stop the vacuuming, add 0.56g of acetic acid (98%) into the four-necked flask, and discharge to obtain a brown-yellow viscous liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com