Biodegradable express bag sealing pressure-sensitive adhesive and preparation method thereof

A technology of pressure-sensitive adhesive and bag sealing, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., and can solve problems such as pollution, waste of resources, and atmospheric environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

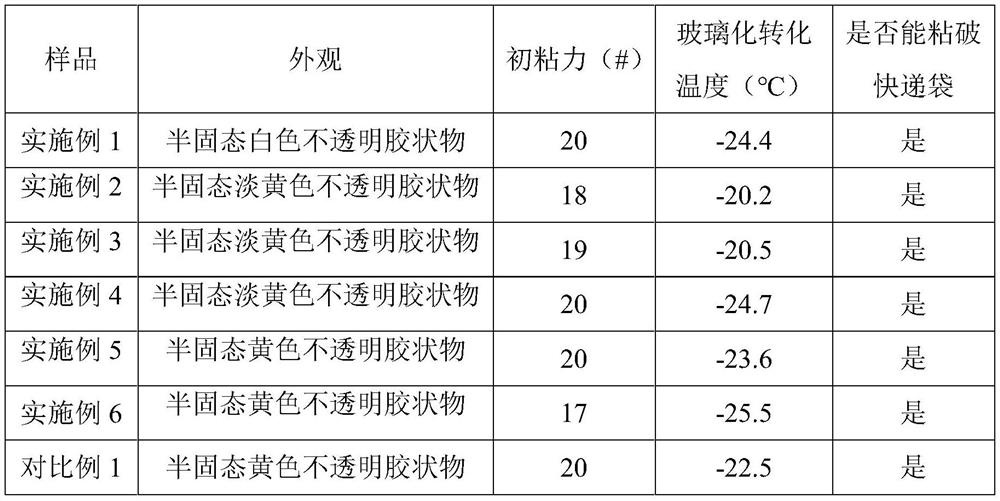

Examples

Embodiment 1

[0033] Add 80 parts of aliphatic polyester adhesive into the reaction kettle, stir and heat up to 180°C under the protection of nitrogen, and the stirring speed is 50 rpm. After the materials in the kettle are completely melted, add 10 parts of hydrogenated rosin and 10 parts of Carbonic acid powder (800 mesh); stop nitrogen, turn on the vacuum pump to evacuate, the vacuum is maintained below 0.01Mpa, the stirring speed is adjusted to 80 rpm, after uniform mixing, heat preservation and pressure holding for 30 minutes; reduce the temperature of the system, when the temperature drops When the temperature is below 120°C, turn off the vacuum pump, slowly return the system pressure to normal pressure, and discharge the material to obtain a semi-solid white opaque express bag sealing adhesive product with an acid value of 23mg KOH / g, a hydroxyl value of 86mg KOH / g, and an initial viscosity of It is 20#.

Embodiment 2

[0035] Add 80 parts of aliphatic polyester adhesive into the reaction kettle, stir and heat up to 180°C under the protection of nitrogen, and the stirring speed is 50 rpm. After the materials in the kettle are completely melted, add 5 parts of terpene resin and 15 parts of carbon dioxide powder (1200 mesh); stop feeding nitrogen, turn on the vacuum pump to evacuate, the vacuum degree is maintained below 0.01Mpa, the stirring speed is adjusted to 80 rpm, after uniform mixing, heat preservation and pressure holding for 30 minutes; When the temperature drops below 120°C, turn off the vacuum pump, slowly restore the system pressure to normal pressure, and discharge the material to obtain a semi-solid light yellow opaque express bag sealing glue product with an acid value of 68 mg KOH / g and a hydroxyl value of 102 mg KOH / g. The viscosity is 18#.

Embodiment 3

[0037] Add 80 parts of aliphatic polyester adhesive into the reaction kettle, stir and heat up to 180°C under the protection of nitrogen, and the stirring speed is 50 rpm. After the materials in the kettle are completely melted, add 5 parts of terpene resin, 5 parts rosin glyceride and 10 parts of talcum powder (1200 mesh); stop nitrogen, turn on the vacuum pump to vacuum, the vacuum is maintained below 0.01Mpa, the stirring speed is adjusted to 80 rpm, after uniform mixing, heat preservation and pressure holding for 30 minutes ; reduce the temperature of the system, when the temperature drops below 120 ° C, turn off the vacuum pump, make the system pressure slowly return to normal pressure, discharge, and obtain the semi-solid light yellow opaque express bag sealing glue product, the acid value is 54mg KOH / g, the hydroxyl value It is 116mg KOH / g, and the initial viscosity is 19#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com