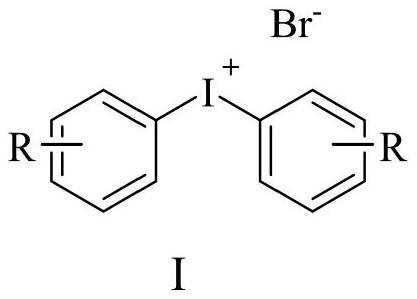

Application of diaryliodonium salt compound in preparation of glass antifogging agent

A technology of salt compound and diaryl iodide, which is applied in the field of anti-fogging agent preparation, can solve the problem of unsustainable anti-fogging effect and achieve the effect of simple synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

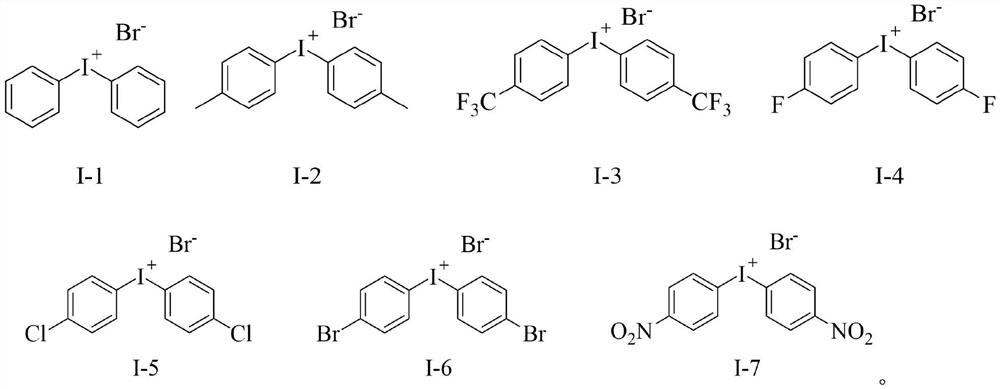

Examples

Embodiment 1

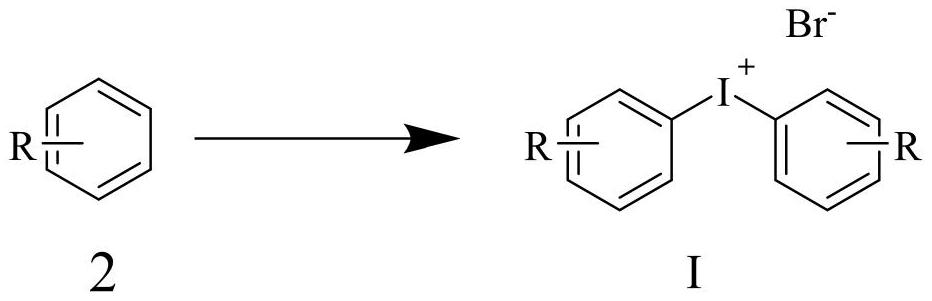

[0028] Preparation method of diryl iodide compound I-1:

[0029]

[0030] Benzene (50.00 mmol) was dissolved in 30 ml of concentrated sulfuric acid, and the temperature was raised to 56 ° C, and sodium highly iodate (1.86 g, 8.70 mmol) was added, and the temperature was continued at a temperature of 60 ° C. Hour. After the reaction is complete, it is cooled to room temperature, and then the reaction solution is poured into the ice water mixture, and the filter residue is discarded under reduced pressure. The filtrate is extracted 5 times with ethyl acetate, discard the organic phase, and potassium bromide into the water phase (5.00 G, 35.00 mmol) Aqueous solution of 35 mL, stirred vigorously for 2 hours, precipitated solid, decompression filtration, water washed to the filtrate, and dried on a surface vessel to give a white solid compound I-1 (65% yield of 65%). 1 HNMR (400 MHz, DMSO) δ8.18 (D, J = 8.8 Hz, 4H), 7.69 (T, J = 7.9 Hz, 2H), 7.50 (T, J = 7.8 Hz, 4H).

Embodiment 2

[0032] Preparation method of diryl iodide compound I-3:

[0033]

[0034] Trifluoromethylbenzene (52.00 mmol) was dissolved in 50 ml of concentrated sulfuric acid, and the temperature was raised to 60 ° C, and sodium metatanate (1.88 g, 8.60 mmol) was added, and the temperature was 60 ° C in 2.0 hours. Continue to react 2.0 hours. After the reaction was complete, then cooled to room temperature, and then poured the reaction liquid into the ice water mixture, and the filtration was discarded under reduced pressure. The filtrate was extracted 5 times with ethyl acetate, discarded the organic phase, and potassium bromide into the water phase (7.00 G, 38.00 mmol) Aqueous solution 35ml, stirred vigorously for 3 hours, precipitated solid, decompression filtration, water washed to the filtrate, and dried on a surface vessel to give a white solid compound I-3 (64% yield of 64%). 1 HNMR (400 MHz, DMSO) δ8.45 (D, J = 9.1 Hz, 4H), 7.55 (M, 4H).

Embodiment 3

[0036] Preparation method of diryl iodide compound I-4:

[0037]

[0038] The fluorine (51.00 mmol) was dissolved in 40 ml of concentrated sulfuric acid, and the temperature was raised to 58 ° C, and the sodium metatanate (1.86 g, 8.70 mmol) was added, and the temperature was continued under conditions of 60 ° C. 1.6 hours. After the reaction was complete, then cooled to room temperature, and then poured the reaction liquid into the ice water mixture, and the filtration was discarded under reduced pressure. The filtrate was extracted 5 times with ethyl acetate, discarded the organic phase, and potassium bromide into the water phase (6.00 G, 36.00 mmol) Aqueous solution was 35mL, stirred vigorously for 2 hours, precipitated solid, decompression filtration, water washed to the filtrate, and dried on a surface vessel to give a white solid compound I-4 (68% yield of 68%). 1 H NMR (400 MHz, DMSO) Δ8.40 (D, J = 8.9 Hz, 4H), 7.45 (M, 4H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com