Debaryomyces hansenii capable of improving flavor of dried sausages and application of debaryomyces hansenii

A technology for yeast and air-dried sausage, applied in the field of Debaryomyces hansenii, can solve the problems of changing local flavor characteristics and reducing the complexity of product aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the preparation method of air-dried sausage

[0027] (1) Preparation of Debariae hansenii SH4 culture: Debariae hansenii SH4 was cultured with YPD liquid medium at 28°C for 24 hours, and the obtained culture liquid was centrifuged at 4°C and 6000×g 10 minutes, then washed twice with sterile deionized water and resuspended in sterile deionized water to make a bacterial suspension.

[0028] (2) Trim the fresh pork rump and pig back fat, remove the fascia etc. on the surface, and grind them on a 1.5cm orifice plate with a meat grinder respectively. The pork rump and pig back fat are 9 : 1 ratio and mix evenly to form meat filling.

[0029] (3) Seasonings are added to the meat filling according to the meat weight of the raw meat: 2.5% of salt, 1% of soft white sugar, 0.3% of monosodium glutamate, 0.009% of sodium nitrite, 1% of Yuquan Daqu, 5% of water and 0.8% of spices. Spices include orange peel, amomum, cloves, nutmeg, angelica, cinnamon and cumin.

[0...

Embodiment 2

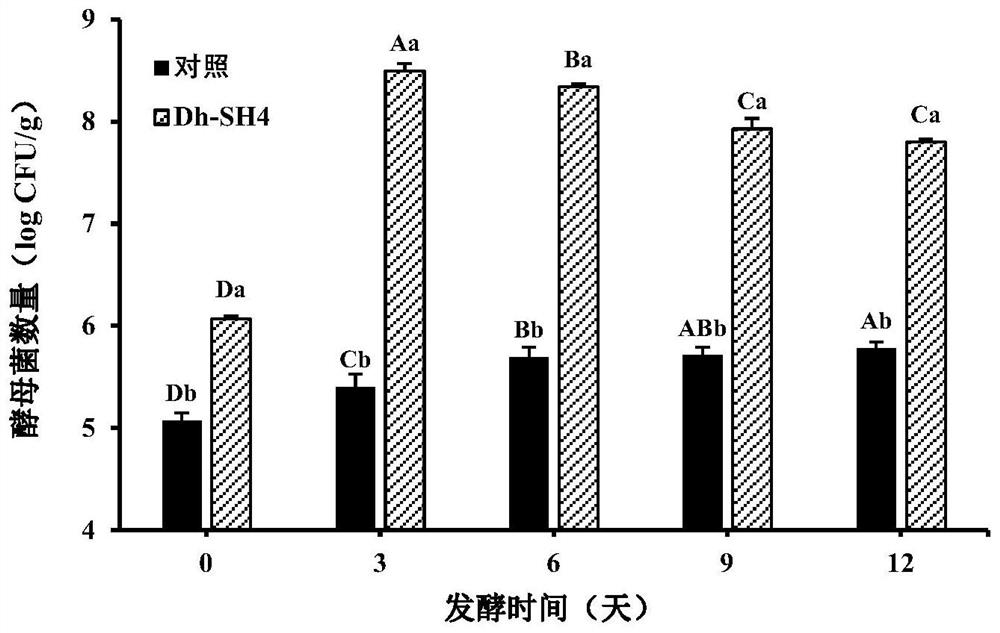

[0033] Embodiment 2: Determination of the number of yeasts in air-dried sausage

[0034] The air-dried sausages prepared in Example 1 were used to measure the number of yeasts on the 0th, 3rd, 6th, 9th and 12th day of the fermentation process. The air-dried sausages of the treatment group and the control group were removed from the casings under aseptic conditions, minced, and 25.0 g of the minced air-dried sausages were taken, added to 225 mL of sterile normal saline, uniformly mixed, and then gradually diluted, and the appropriate dilution was selected. Bacterial liquid was cultured on YPD solid medium at 28°C for 5 days and plate count was performed.

[0035] The result is as figure 1As shown, the number of yeasts in the treatment group increased significantly during the 0-3 days of fermentation, and then gradually decreased (P<0.05). The number of yeasts in the control group showed a gradual upward trend during the fermentation process (P<0.05). At the same fermentation...

Embodiment 3

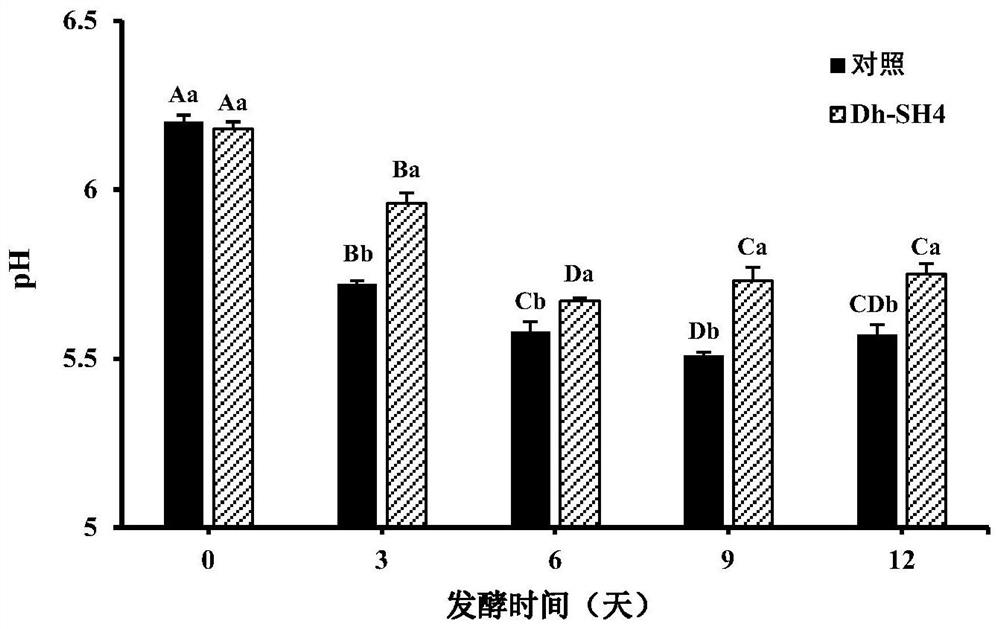

[0036] Embodiment 3: the mensuration of pH in the air-dried sausage

[0037] The pH values of the air-dried sausages prepared in Example 1 were measured on days 0, 3, 6, 9 and 12 during the fermentation process. Accurately weigh 10.0 g of minced air-dried sausage, add 90 mL of distilled water, stir for 30 minutes, filter, and take the supernatant to measure with a pH meter.

[0038] The result is as figure 2 As shown, the pH value in the treatment group decreased significantly during the 0-6 days of fermentation, and then gradually increased (P<0.05). The pH value of the control group decreased significantly (P<0.05) during the 0-9 days of fermentation, and then slightly increased. After 3-12 days of fermentation, the pH values in the treatment group were significantly higher than those in the control group (P<0.05). On the 12th day of fermentation, the pH value in the treatment group was 5.75, which was higher than 5.57 in the control group, which may be due to the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com