Pyrolysis recovery method for organic components of waste light-emitting diodes

A technology for light-emitting diodes and a recycling method is applied in the field of pyrolysis recovery of waste light-emitting diode organic components, which can solve the problems of not considering the recovery of organic components, and achieve the effect of being beneficial to comprehensive recovery and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

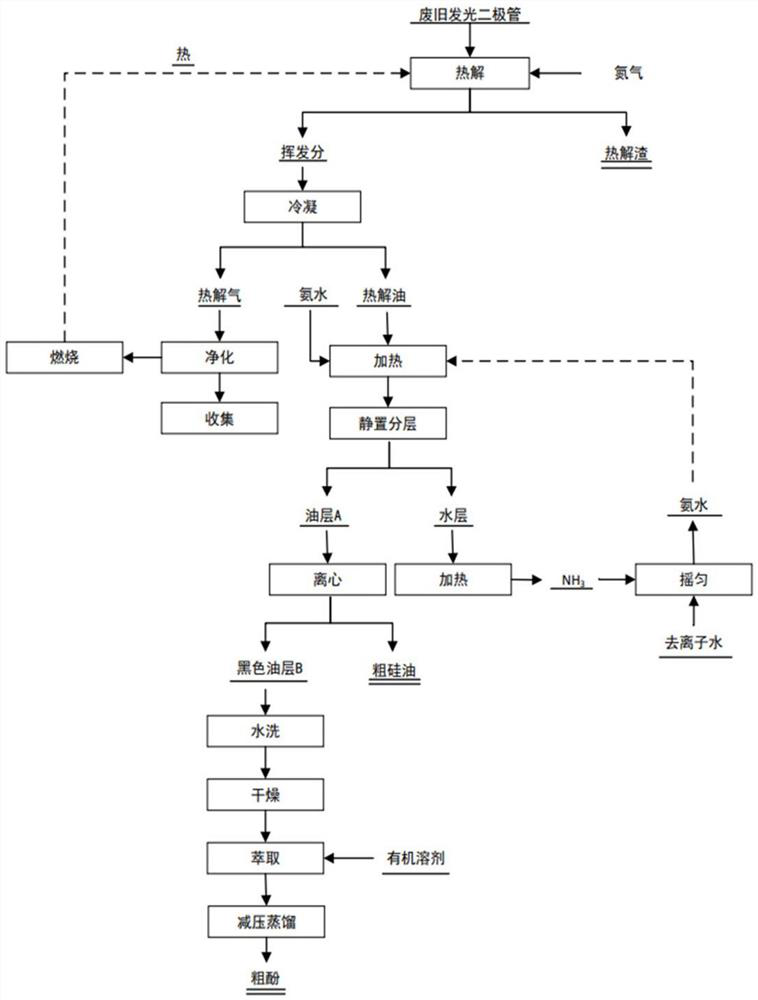

[0027] Follow the steps below to recycle:

[0028] Put the waste light-emitting diodes into the pyrolysis furnace, and continuously feed argon; under the condition of argon atmosphere, heat up to 300°C and keep it warm for 60 minutes to obtain volatile matter and pyrolysis slag; condense the volatile matter to obtain pyrolysis oil and pyrolysis gas; after purification and combustion, the pyrolysis gas can be used as an energy source to provide heat for pyrolysis; add 15mol / L ammonia water to the pyrolysis oil, the ratio of alkali to oil is 2:1, stir and react at 20°C for 12 minutes, then stand for separation liquid to obtain water layer and oil layer A; the water layer is heated to collect volatilized ammonia gas, which can be reused; oil layer A is centrifuged, and black oil layer B and crude silicon oil are obtained after liquid separation; black oil layer B is washed with water and dried , extracted 3 times with benzene, and distilled under reduced pressure to obtain crude ...

Embodiment 2

[0030] Follow the steps below to recycle:

[0031] Put the waste light-emitting diodes into the pyrolysis furnace, and continuously pass in argon; under the condition of argon atmosphere, heat up to 350°C and keep it warm for 60 minutes to obtain volatile matter and pyrolysis residue; condense the volatile matter to obtain pyrolysis oil and pyrolysis gas; after purification and combustion, the pyrolysis gas can be used as an energy source to provide heat for pyrolysis; add 15mol / L ammonia water to the pyrolysis oil, the ratio of alkali to oil is 1:2, stir and react at 80°C for 15 minutes, then stand and separate liquid to obtain water layer and oil layer A; the water layer is heated to collect volatilized ammonia gas, which can be reused; oil layer A is centrifuged, and black oil layer B and crude silicon oil are obtained after liquid separation; black oil layer B is washed with water and dried , extracted twice with benzene, and distilled under reduced pressure to obtain crud...

Embodiment 3

[0033] Follow the steps below to recycle:

[0034] Put the waste light-emitting diodes into the pyrolysis furnace, and continuously pass in argon; under the condition of argon atmosphere, heat up to 400°C and keep it warm for 50 minutes to obtain volatile matter and pyrolysis slag; condense the volatile matter to obtain pyrolysis oil and pyrolysis gas; after purification and combustion, the pyrolysis gas can be used as an energy source to provide heat for pyrolysis; add 13mol / L ammonia water to the pyrolysis oil, the ratio of alkali to oil is 3:2, stir and react at 50°C for 18 minutes, then stand for separation liquid to obtain water layer and oil layer A; the water layer is heated to collect volatilized ammonia gas, which can be reused; oil layer A is centrifuged, and black oil layer B and crude silicon oil are obtained after liquid separation; black oil layer B is washed with water and dried , extracted twice with benzene, and distilled under reduced pressure to obtain crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com