1T-MoS2/NiS heterogeneous interface structure catalyst for electro-catalytic hydrogen evolution as well as preparation method and application of 1T-MoS2/NiS heterogeneous interface structure catalyst

A structural catalyst, 1t-mos2 technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of low current density and high overpotential of hydrogen evolution reaction, and achieve the effect of improving hydrogen evolution catalytic activity, excellent performance and excellent environmental interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

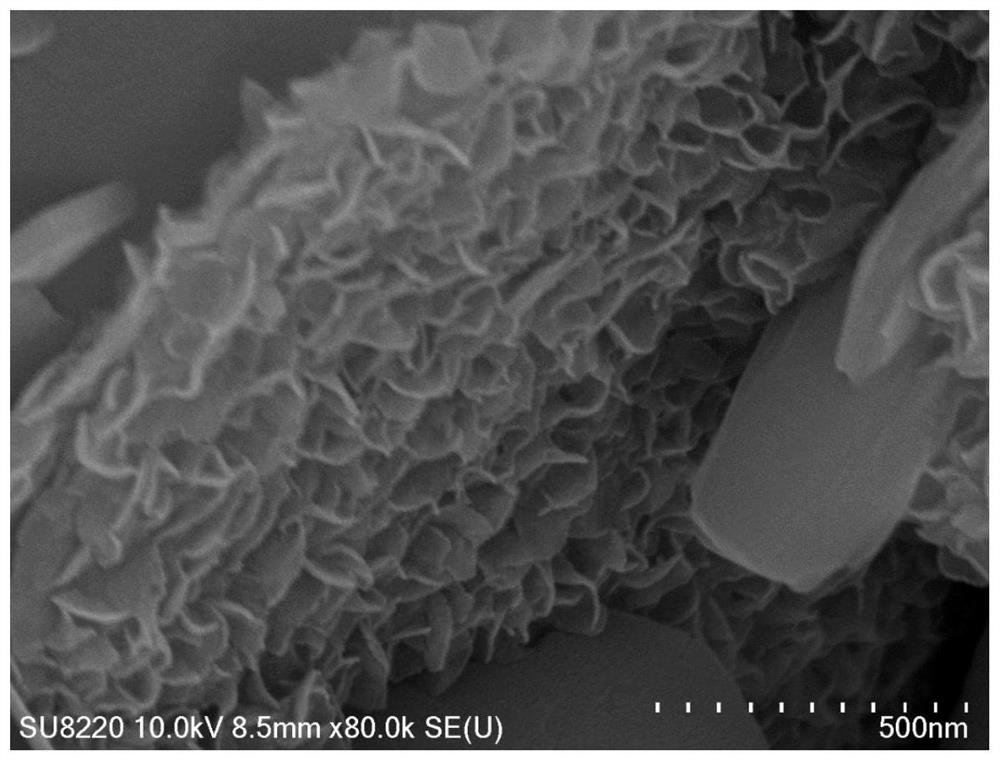

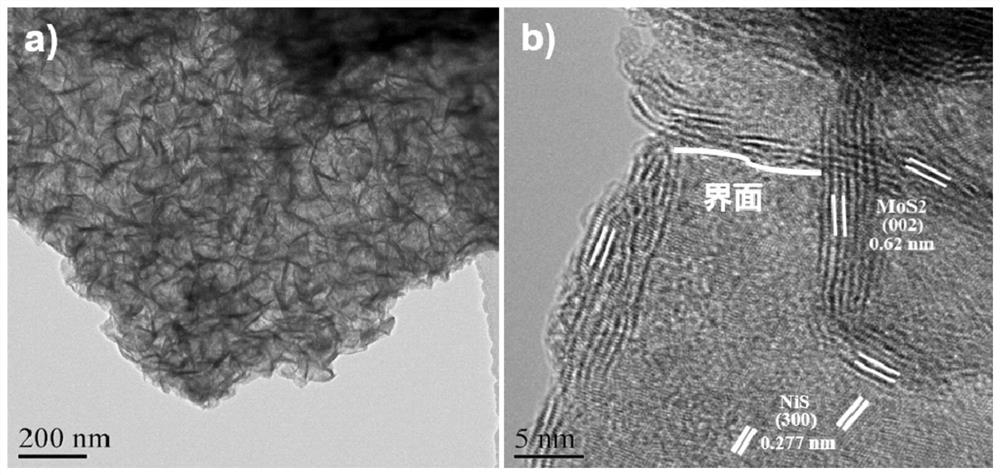

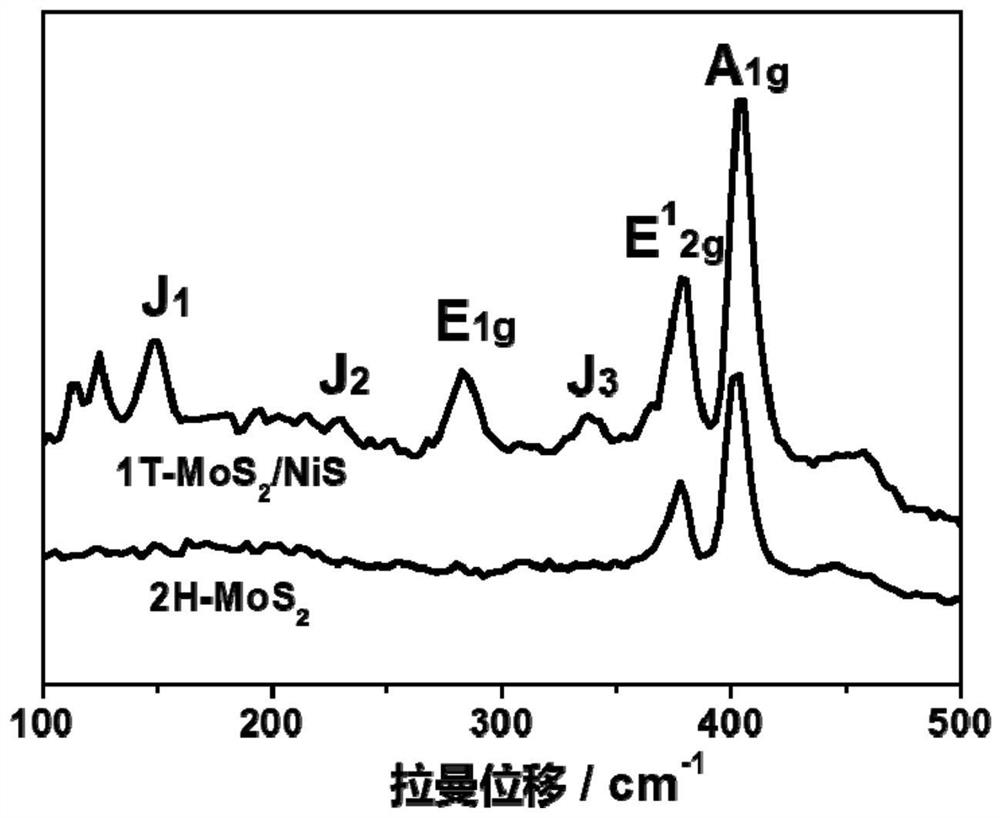

[0041] A 1T-MoS for electrocatalytic hydrogen evolution 2 / NiS heterogeneous interface structure catalyst preparation method is specifically completed according to the following steps:

[0042] Step 1, synthesizing the Ni nanosheet skeleton.

[0043] (1) Dissolve 0.1g (mass concentration of 4.0g / L) nickel acetylacetonate in a mixed solution of 20mL N,N-dimethylformamide (DMF), 1mL 1-n-butylamine and 4mL deionized water, Stir ultrasonically at room temperature for 30 minutes, and the ultrasonic frequency is 35kHz to form a homogeneous solution;

[0044] (2) Then transfer the above solution to a 50mL PPL-lined reactor, put it in an oven, and react at 200°C for 48h;

[0045] (3) After the reaction, the gray-black powder was collected by centrifugation at a speed of 9000 r / min, washed with deionized water, and then vacuum-dried at 60° C. for 12 hours. The obtained precursor was called Ni nanosheets.

[0046] Step 2. Synthesis of 1T-MoS 2 / NiS heterostructure catalyst.

[0047...

Embodiment 2

[0052] A 1T-MoS for electrocatalytic hydrogen evolution 2 / NiS heterogeneous interface structure catalyst preparation method is specifically completed according to the following steps:

[0053] Step 1, synthesizing the Ni nanosheet skeleton.

[0054] (1) Synthesize the Ni nanosheet skeleton according to the step 1 of embodiment 1.

[0055] Step 2. Synthesis of 1T-MoS 2 / NiS heterostructure catalyst.

[0056] (1) Get 1mmol of the above-mentioned Ni nanosheets, 1mmol sodium molybdate, and 2.5mmol KSCN dissolved in a mixed solution of 10mL of ethanol and deionized water (V 乙醇 :V 水 =2:8), ultrasonically stirred at room temperature for 30min, and the ultrasonic frequency was 35kHz to form a homogeneous solution;

[0057] (2) Then the above solution was transferred to a 50mL polytetrafluoroethylene-lined reactor, placed in an oven, and reacted at 180°C for 20h, and the reaction heating rate was 3°C / min;

[0058] (3) After the reaction, the gray-black powder was collected by ce...

Embodiment 3

[0060] A 1T-MoS for electrocatalytic hydrogen evolution 2 / NiS heterogeneous interface structure catalyst preparation method is specifically completed according to the following steps:

[0061] Step 1, synthesizing the Ni nanosheet skeleton.

[0062] (1) Synthesize the Ni nanosheet skeleton according to the step 1 of embodiment 1.

[0063] Step 2. Synthesis of 1T-MoS 2 / NiS heterostructure catalyst.

[0064] (1) Take 1mmol of the above-mentioned Ni nanosheets, 1mmol of MoO 3 , and 2.5mmol of thiourea dissolved in a mixed solution of 10mL of ethanol and deionized water (V 乙醇 :V 水 =2:8), ultrasonically stirred at room temperature for 30min, and the ultrasonic frequency was 35kHz to form a homogeneous solution;

[0065] (2) Then the above solution was transferred to a 50mL polytetrafluoroethylene-lined reactor, placed in an oven, and reacted at 180°C for 20h, and the reaction heating rate was 3°C / min;

[0066] (3) After the reaction, the gray-black powder was collected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com