Positive electrode material and preparation method and application thereof

A technology of positive electrode materials and positive electrode active materials, which is applied in the field of positive electrode materials and its preparation, can solve problems such as battery capacity decay and battery swelling, and achieve less side reactions, good electrical conductivity and ion conductivity, good structural stability and chemical stability. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

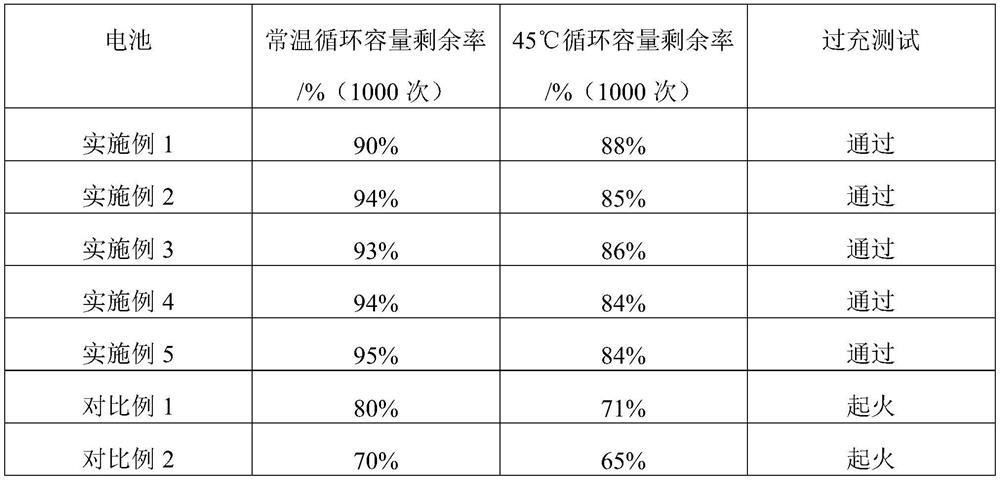

Examples

Embodiment 1

[0044] Preparation of the positive electrode sheet: the polyethylene glycol diallyl ester of 5g of polyethylene glycol methyl ether acrylate, AIBN (0.005g, azobisisobutyronitrile), calcium zeolite of 12g; the TiF of 97.3g 4 ethanol solution; 3g of superconducting carbon black (super-P) (wherein, cross-linked polymer, TiOF 2 The mass ratio to the conductive agent is 17:80:3); 4Kg of NCM811 is dispersed in 1Kg of NMP (N-methylpyrrolidone), heated to 150°C while stirring continuously, and reacted for 15h, and the dispersion is cooled to After room temperature, add 0.104Kg of PVDF (polyvinylidene fluoride) and 0.04Kg of carbon nanotubes in sequence, and make positive electrode sheets according to the current commercial battery manufacturing process.

[0045] Preparation of negative electrode sheet: disperse 2.8Kg graphite, 0.04Kg CMC (sodium carboxymethyl cellulose), 0.058Kg SBR (styrene-butadiene rubber), 0.015Kg Super-P (superconducting graphite) in 2.5Kg deionized water , acco...

Embodiment 2

[0048] The difference with embodiment 1 is:

[0049] The preparation of the positive plate: the polyethylene glycol methyl ether acrylate of 6g, the polyethylene glycol diallyl ether of 2.5g, AIBN (0.002g), calcium zeolite; The TiF of 49g 4 ethanol solution; 1.5g of super-P (wherein, cross-linked polymer, TiOF 2 The mass ratio of the conductive agent to the conductive agent is 17:80:3); 4Kg of NCM811 is dispersed in 1Kg of NMP, heated to 150°C while stirring continuously, reacted for 15h, and stirred continuously until the dispersion is cooled to room temperature, then add 0.104Kg PVDF and 0.04Kg carbon nanotubes are used to make positive plates according to the current commercial battery manufacturing process.

Embodiment 3

[0051] The difference with embodiment 1 is:

[0052] The preparation of positive plate: the polyethylene glycol methyl ether acrylate of 6g, the polyethylene glycol diallyl ether of 2.5g, AIBN (0.002g), calcium zeolite; The TiF of 74g 4 ethanol solution; 1.4g of carbon nanotubes (wherein, cross-linked polymer, TiOF 2 The mass ratio of the conductive agent to the conductive agent is 12:86:2); 4Kg of NCM811 is dispersed in 1Kg of NMP, heated to 150°C while stirring continuously, reacted for 15h, and stirred continuously until the dispersion is cooled to room temperature, then add 0.104Kg PVDF, 0.04Kg of carbon nanotubes, according to the current commercial battery manufacturing process to make the positive sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com