On-line slip ring repairing device and repairing method

A slip ring device and slip ring technology are applied in the field of repair structure of motor slip rings, which can solve the problems of troublesome processing and repair methods, inability to repair wavy pits, and high operation requirements, so as to ensure normal operation and reduce expensive maintenance costs. , Easy to operate, quick and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

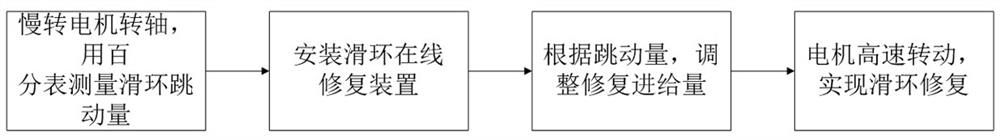

[0043] figure 1 It is a flow chart of online repairing slip ring process. First measure the runout of the slip ring with a dial indicator, and then determine the depth of the slip ring that needs to be polished according to the runout of the slip ring. Adjust the installation height of the device through the depth dimension of the slip ring grinding. When the motor rotates at a high speed, the sandpaper rubs the slip ring to quickly wear off the high points and edges. If there are wavy pits, the simulated carbon brush 33 floats up and down along with the wave to remove the high points. When reaching the set depth, the simulated carbon brush 33 no longer continues to grind downwards, and slowly grinds the high point to the set depth. The simulated carbon brush 33 no longer floats up and down, and when there is no copper powder on the grinding belt, stop the machine and use the dial indicator to detect the grinding result, and if it is qualified, it will be repaired.

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com