Device and method for extracting high-purity arsenic trioxide through nonferrous smelting quenching

An arsenic trioxide, high-purity technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of large lye consumption, system equipment and flue corrosion, and high cost of wastewater fluorine and chlorine removal treatment, and achieve reduction harm, improve service life, and stabilize production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

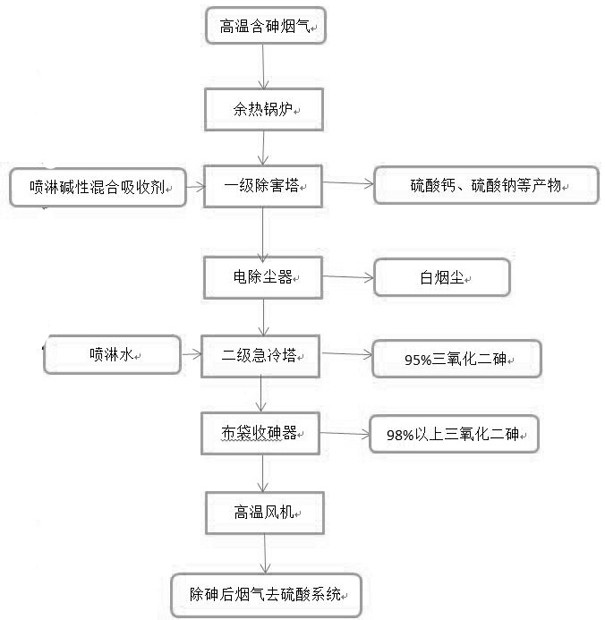

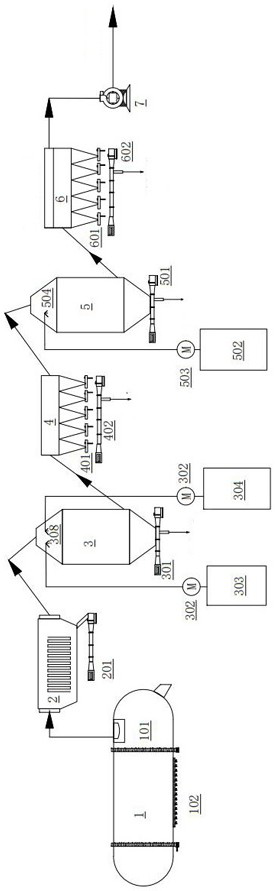

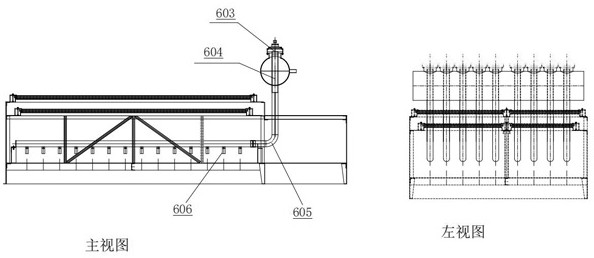

[0028] Such as Figure 1-4 , a device for extracting high-purity arsenic trioxide by rapid cooling in nonferrous smelting, including a smelting furnace 1, a smelting waste heat boiler 2, a first-stage detoxification tower 3, a smelting electrostatic precipitator 4, a second-stage quenching tower 5, a bag arsenic collector 6, and a high-temperature fan 7.

[0029]The smelting furnace 1 is connected to the smelting waste heat boiler 2 through an ascending flue, the smelting waste heat boiler 2 is connected to the first-level detoxification tower 3 through a flue made of carbon steel, and the first-level detoxification tower 3 and the smelting electric precipitator 4 are connected through a carbon steel flue. The flue connection made of steel, the smelting electrostatic precipitator 4 and the secondary quenching tower 5 are connected through the flue made of carbon steel, the secondary quenching tower 5 and 6 are connected by the flue made of carbon steel, and the bag arsenic col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com