Defect-containing silicon carbide biscuit as well as preparation method and nondestructive testing method thereof

A technology of silicon carbide and silicon carbide blanks, applied in the field of silicon carbide blanks and its preparation, can solve the problems that internal defects of silicon carbide blanks cannot be prefabricated, etc., and achieve the effect of simple operation and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The embodiment of the present application provides a method for preparing a silicon carbide biscuit containing defects, comprising the following steps:

[0025] S1, adding solid organic matter in the process of preparing the silicon carbide green body, and performing molding;

[0026] S2, heat-treating the formed silicon carbide green body to decompose the solid organic matter, that is, to obtain a silicon carbide green body containing defects.

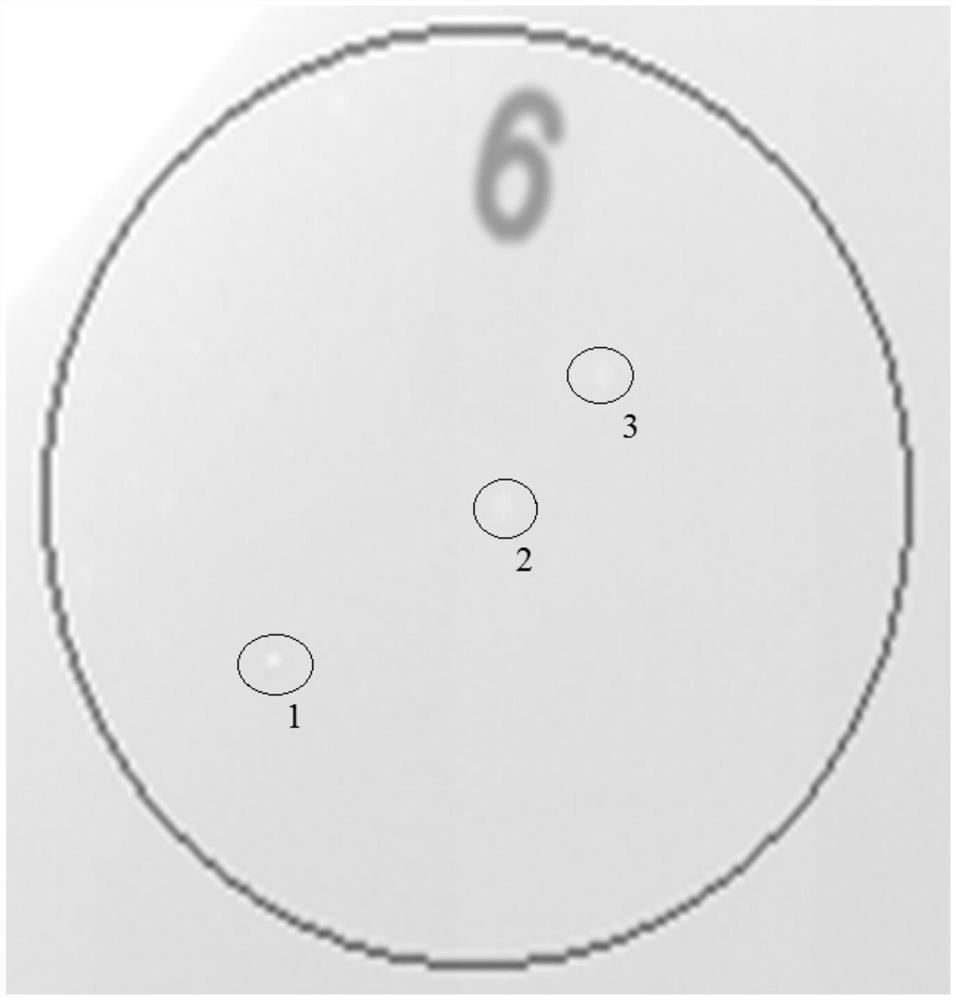

[0027] It should be noted that, in the preparation method of the defect-containing silicon carbide green body of the present application, solid organic matter is added in the process of preparing the silicon carbide green body, and high-temperature heat treatment is used to decompose the solid organic matter into gas and remove it, so that after The position of the solid organic matter in the silicon carbide body will leave certain defects. The shape, size and quantity of the defect can be controlled. At the same time, the adde...

Embodiment 1

[0042] The method for preparing a defect-containing silicon carbide biscuit provided in the embodiment of the present application includes the following steps:

[0043] S1. Add 50g of acrylamide and 25g of methylenebisacrylamide into 1000ml of water and mix evenly to obtain a premix;

[0044] S2. Add 3000g of silicon carbide powder and 3g of spherical epoxy resin to the premix, and stir to obtain a slurry;

[0045] S3. Add 1ml of tetramethylethylenediamine and ammonium persulfate solution to the slurry to continue stirring, then pour it into a mold, and after curing and molding, place it in a constant temperature and humidity cabinet to dry to obtain a silicon carbide green body; wherein ammonium persulfate The preparation method of the solution is: add 8g of ammonium persulfate into 10g of water, and dissolve to obtain the ammonium persulfate solution;

[0046] S4. Put the silicon carbide green body in a vacuum sintering furnace, first raise the temperature from room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com