Device for preparing optical component by sol and preparation method thereof

A technology for optical components and preparation devices, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve problems such as poor quality of optical components, narrow application range, unstable performance, etc., to improve quality and precision, and ensure reliable equipment The effect of high precision and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation of Silica Optical Glass Components Doped with Metal Ions

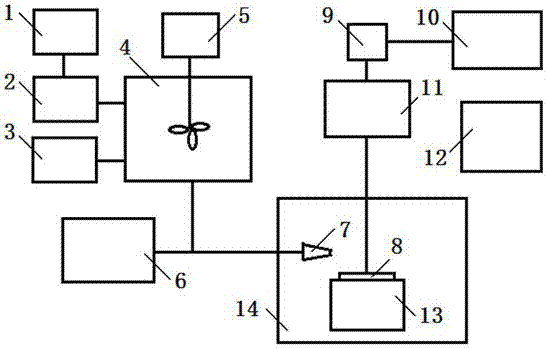

[0051] 500 ml of absolute ethanol in the solvent kettle 1, 15ml of tetraethyl orthosilicate in the raw material kettle 2, and 2.5ml of ammonia water in the catalyst kettle 3 are sent to the raw material mixing chamber 4, and a certain proportion of europium nitrate compound is added to the raw material. Under the control of the stirrer 5, stir for 24 hours to obtain a tetraethyl orthosilicate sol containing europium ions. The high-pressure gas generated by the high-pressure gas generator 6 is used to uniformly spray the sol onto the substrate 8 through the nozzle 7 to form a sol layer on the surface of the substrate 8 . The laser 9 generates a laser beam under the excitation of the laser power supply 10, and the laser beam is irradiated on the substrate 8 sprayed with a uniform sol layer through the beam converter 11, and the irradiation energy and time are controlled to carry out condensation reacti...

Embodiment 2

[0053] Preparation of CdS-SiO 2 Composite nonlinear optics

[0054] The C in solvent kettle 1 2 h 5 OH, tetraethyl orthosilicate (TEOS) in raw material tank 2, HNO in catalyst tank 3 3 , press n(TEOS): n(H 2 O): n(C 2 h 5 OH) = 1:5:2.5 molar ratio feeding, then sent into the raw material mixing chamber 4, after stirring at a high speed of the stirrer 5 for 1 hour, add a certain amount of Cd (NO 3 ) 2 , after stirring for 0.5 hours, add thioacetamide (TAA), Cd(NO 3 ) 2 : n(TAA): n(TEOS)=1:1.5:4, get CdS / SiO 2 Sol, the high-pressure gas generated by the high-pressure gas generator 6 is used to uniformly spray the sol onto the substrate 8 through the nozzle 7 to form a sol layer on the surface of the substrate 8 . The laser 9 generates a laser beam under the excitation of the laser power supply 10, and the laser beam is irradiated onto the substrate 8 sprayed with a uniform sol layer through the beam converter 11, and the irradiation energy and time are controlled for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com