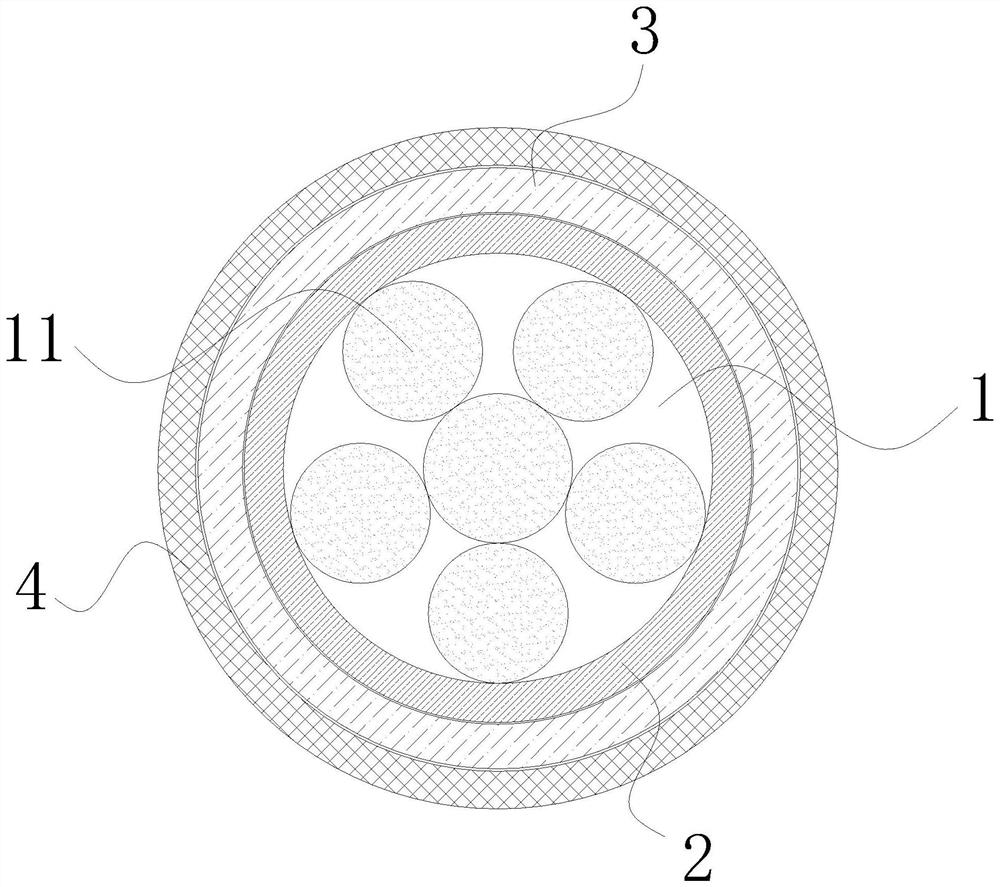

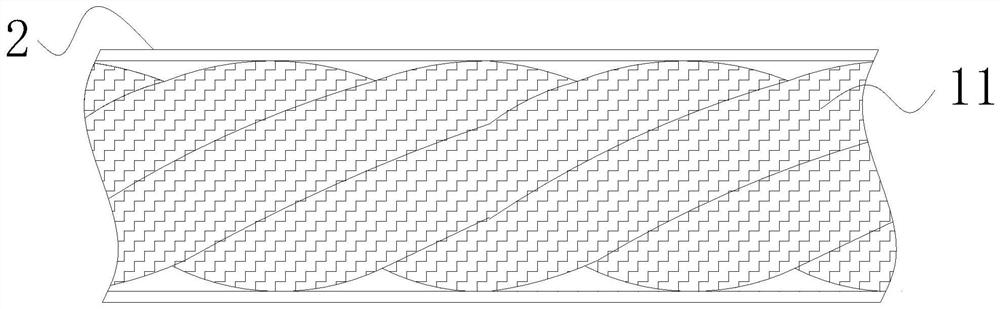

Photovoltaic cable and preparation method and application thereof

A photovoltaic cable and cable core technology, applied in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., can solve the problems of high cost, complex production process, inability to be widely used in large-scale promotion, and improve the overall structural strength. , The effect of ensuring normal work, extending working life and using time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

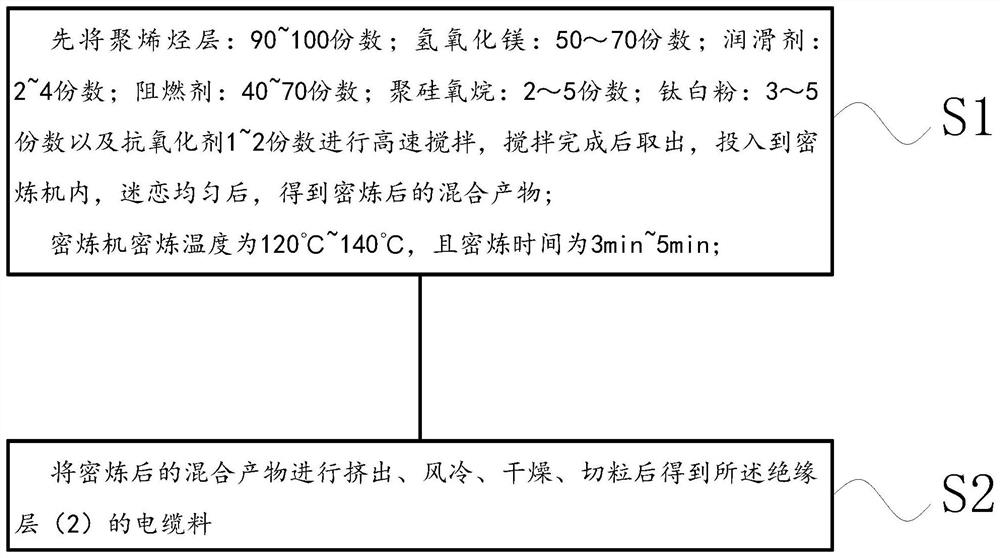

[0047] Wherein, the insulating layer 2, the wear-resistant layer 3 and the protective layer 4 are all composed of the following components by mass:

[0048] Insulation layer 2 includes: polyolefin layer: 90 parts; magnesium hydroxide: 50 parts; lubricant: 2 parts; flame retardant: 40 parts; polysiloxane: 2 parts; titanium dioxide: 3 parts Quantity; Antioxidant 1 part;

[0049] Wear-resistant layer 3 includes: EPDM rubber: 170 parts; white carbon black: 10 parts; softener: 5 parts; zinc oxide: 2 parts; sulfur: 1 part; anti-aging agent: 1 part ;

[0050] The protective layer 4 includes: flame retardant: 50 parts; polysiloxane: 2 parts; titanium dioxide: 3 parts; aluminum hydroxide or magnesium hydroxide: 10 parts; polyolefin layer: 90 parts; 2 servings of agent; 1 serving of antioxidant;

[0051] The polyolefin layer includes: polyethylene, polystyrene, polypropylene or a mixture of the two;

[0052] The lubricant is at least one of zinc stearate, calcium stearate, magnesium...

Embodiment 2

[0072] Wherein, the insulating layer 2, the wear-resistant layer 3 and the protective layer 4 are all composed of the following components by mass:

[0073] Insulation layer 2 includes: polyolefin layer: 100 parts; magnesium hydroxide: 70 parts; lubricant: 4 parts; flame retardant: 70 parts; polysiloxane: 5 parts; titanium dioxide: 5 parts number; 2 servings of antioxidants;

[0074] Wear-resistant layer 3 includes: EPDM rubber: 180 parts; white carbon black: 20 parts; softener: 20 parts; zinc oxide: 6 parts; sulfur: 2 parts; anti-aging agent: 2 parts ;

[0075] The protective layer 4 includes: flame retardant: 70 parts; polysiloxane: 5 parts; titanium dioxide: 5 parts; aluminum hydroxide or magnesium hydroxide: 20 parts; polyolefin layer: 110 parts; 4 servings of anti-oxidants; 2 servings of antioxidants;

[0076] The polyolefin layer includes: polyethylene, polystyrene, polypropylene or a mixture of the two;

[0077] The lubricant is at least one of zinc stearate, calciu...

Embodiment 3

[0097] Wherein, the insulating layer 2, the wear-resistant layer 3 and the protective layer 4 are all composed of the following components by mass:

[0098] Insulation layer 2 includes: polyolefin layer: 95 parts; magnesium hydroxide: 60 parts; lubricant: 3 parts; flame retardant: 55 parts; polysiloxane: 3 parts; titanium dioxide: 4 parts Quantity; Antioxidant 1 part;

[0099] Wear-resistant layer 3 includes: EPDM rubber: 175 parts; white carbon black: 16 parts; softener: 14 parts; zinc oxide: 4 parts; sulfur: 1 part; anti-aging agent: 2 parts ;

[0100] The protective layer 4 includes: flame retardant: 60 parts; polysiloxane: 4 parts; titanium dioxide: 4 parts; aluminum hydroxide or magnesium hydroxide: 16 parts; polyolefin layer: 100 parts; 3 servings of agent; 2 servings of antioxidant;

[0101] The polyolefin layer includes: polyethylene, polystyrene, polypropylene or a mixture of the two;

[0102] The lubricant is at least one of zinc stearate, calcium stearate, magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com