Synthesis method of carbon nanotube coated FeF3

A technology of carbon nanotubes and synthesis methods, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as electrolyte side reactions, volume expansion and contraction, poor conductivity, etc., to achieve improved The effect of conductivity, low cost and poor uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

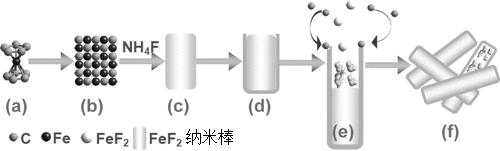

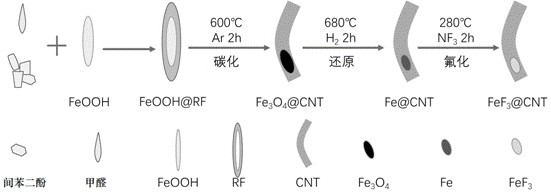

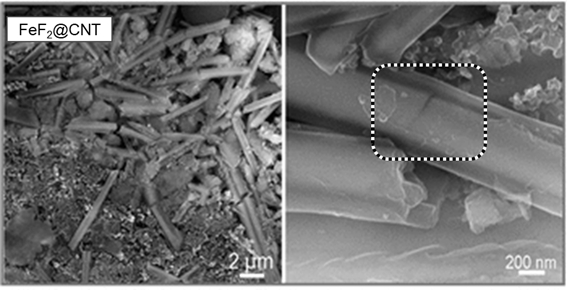

[0035] A carbon nanotube coated FeF 3 The synthetic method comprises the steps:

[0036] (1) Coating: Disperse 120mg of iron oxyhydroxide (FeOOH) in 120mL of deionized water, and after mechanically stirring for 10 minutes under ultrasonic, add 600mg of cetyltrimethylammonium bromide (CTAB), 1000mg of m-phthalide Phenol (Resorcinol) and 30mL ethanol, continue ultrasonic mechanical stirring for 10min, and finally add 500μL ammonia water (NH 3 ·H 2 O) and 1000 μL formaldehyde solution (Formaldehyde), in which the mass concentration of formaldehyde solution is 37%, the mass concentration of ammonia water is 25%, keep mechanical stirring under ultrasonic for 1h. The obtained dispersion was centrifuged, washed with water and alcohol three times each, and dried in a vacuum oven at 60°C for 6 hours.

[0037] (2) Carbonization and reduction: Put the obtained dried FeOOH@RF into a burning boat, raise the temperature to 600°C at room temperature at a rate of 1.5°C / min, keep it at 600°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com