High-temperature sodium ion battery electrolyte, functional additive and sodium ion battery

A sodium-ion battery and functional additive technology, which is applied in the high-temperature sodium-ion battery electrolyte, functional additive and sodium-ion battery fields, can solve problems such as poor performance at low temperature, high viscosity of the electrolyte, and poor wetting of the pole piece. Achieve the effects of improving high-temperature cycle performance, improving dissolution, and reducing continuous decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

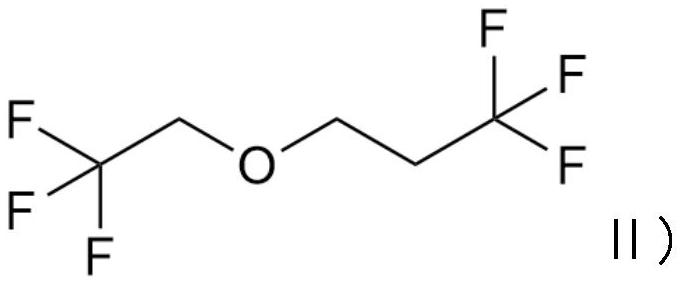

[0034] Electrolyte solution A is prepared by using the compound represented by formula (II).

[0035]

[0036] In a glove box with moisture less than 0.1ppm, oxygen less than 0.1ppm, and filled with argon, ethylene carbonate (EC), diethyl carbonate (DEC), and ethyl methyl carbonate (EMC) were mixed according to the mass ratio of 3: 2: Mix evenly in a ratio of 5, add bisfluorosulfonimide sodium salt (NaFSI), the concentration of sodium salt is 1 mol L -1 , respectively add auxiliary additives ethylene carbonate (VC), 1,3-propane sultone (PS) and vinyl sulfate (DTD) according to 1%, 1%, and 1% of the total mass fraction of the electrolyte, and then add 5 wt% of the compound (II) to obtain the high-temperature sodium-ion battery electrolyte A.

Embodiment 2

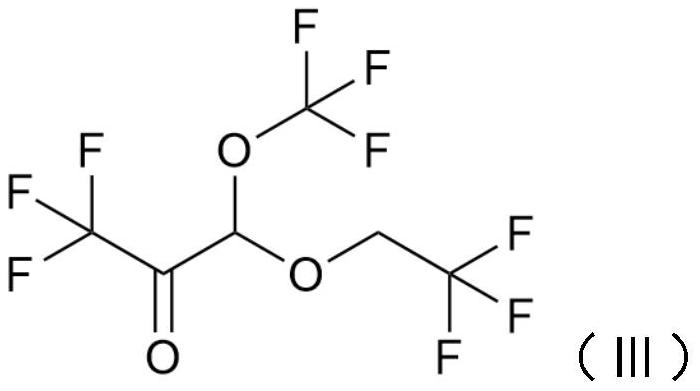

[0038] Electrolyte B was prepared using the compound of formula (III).

[0039]

[0040]In a glove box with moisture less than 0.1ppm, oxygen less than 0.1ppm, and filled with argon, ethylene carbonate (EC), diethyl carbonate (DEC), and ethyl methyl carbonate (EMC) were mixed according to the mass ratio of 3: 2: Mix evenly in a ratio of 5, add bisfluorosulfonimide sodium salt (NaFSI), the concentration of sodium salt is 1 mol L -1 , add auxiliary additives ethylene carbonate (VC), 1,3-(1-propene) sultone (PST) and N,N dicyclohexyl Carbodiimide (DCC), and then add 10 wt% of compound (III) to obtain high-temperature sodium-ion battery electrolyte B.

Embodiment 3

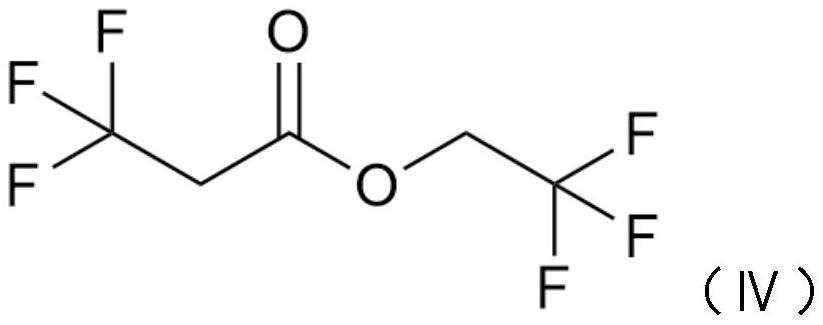

[0042] Electrolyte C is prepared by using the compound of formula (IV).

[0043]

[0044] In a glove box with moisture less than 0.1ppm, oxygen less than 0.1ppm, and filled with argon, ethylene carbonate (EC), diethyl carbonate (DEC), and ethyl methyl carbonate (EMC) were mixed according to the mass ratio of 3: 2: Mix evenly in a ratio of 5, add bisfluorosulfonimide sodium salt (NaFSI), the concentration of sodium salt is 1 mol L -1 , respectively add auxiliary additives ethylene carbonate (VC), 1,3-(1-propene) sultone (PST) and succinic anhydride (SA) according to 1%, 1% and 1% of the total mass fraction of the electrolyte, Then add 5wt% of the compound (III) to obtain the high temperature sodium ion battery electrolyte C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com