Food ultrasonic coupling enzymolysis freeze-drying preparation system

An ultrasonic coupling and preparation system technology, which is applied in food drying, food ultrasonic treatment, food homogenization, etc., can solve the backward production process of reconstituted freeze-dried food, strict workshop cleanliness and space requirements, and process adaptation It can solve the problems of poor product taste and brewability, solve retrograde and allergenicity, and save water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

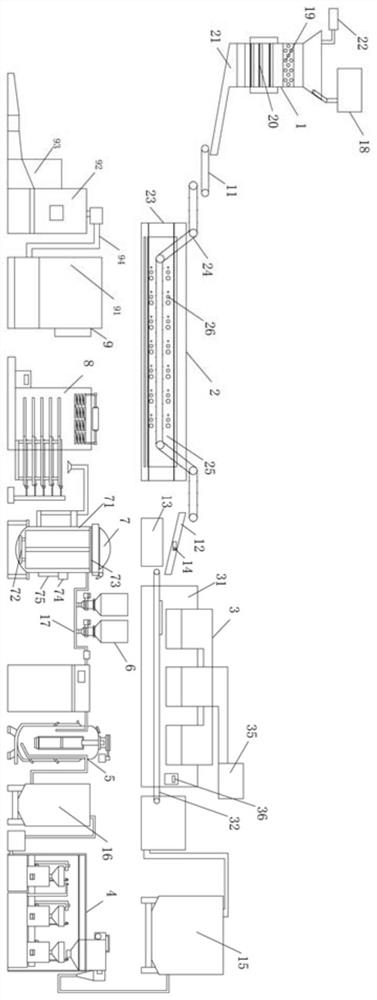

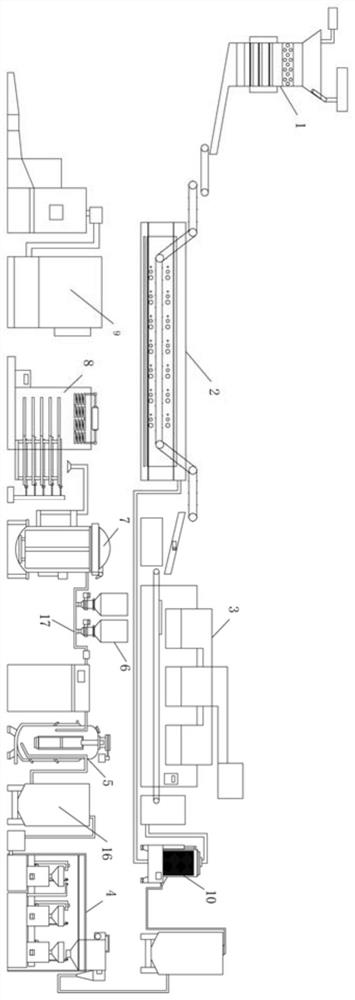

[0050] In this example, freeze-dried rice flour is prepared by using this food ultrasonic-coupled enzymatic freeze-drying preparation system. The preparation process includes screening, cleaning, drying, refining, ultrasonic-coupled enzymatic hydrolysis, cooking and sterilization, blending, and homogenization of raw rice. , freeze-drying, storage, packaging, and storage.

[0051] During processing, first put the rice selected from the raw material to be processed into the raw material screening device 1, and then rotate along the inner wall of the feed chute through the feeding tube and fall from the discharge port of the feed chute into the magnetic grid screening mechanism 19 of the raw material screening device 1 below. In the process of unloading, the dust removal mechanism 22 starts at the same time, and the mixed dust raised when the rice grains collide with each other is first sucked away by the breeze dust suction treatment, and the operator adjusts the magnetic adjustm...

no. 2 example

[0062] This example is similar to Example 1, except that the soybeans selected for processing raw materials are used to prepare freeze-dried soybean powder. In this example, the preparation process is the screening, cleaning, drying, peeling, thermal passivation, and drying of raw soybeans. Refining, super-coupled enzymatic hydrolysis, cooking and sterilization, blending, homogenization, freeze-drying, cutting, and storage.

[0063] like figure 2 As shown, during processing, the non-transgenic soybeans selected as raw materials to be processed are first put into the raw material screening device 1, and then the feeding pipe rotates along the inner wall of the guide trough and falls into the bottom of the raw material screening device 1 from the outlet of the guide trough. On the magnetic grid screening mechanism 19, the dust removal mechanism 22 starts at the same time during the process of unloading, and the mixed dust raised when the soybeans collide with each other is firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com