Preparation method of sub-nano porous PES film

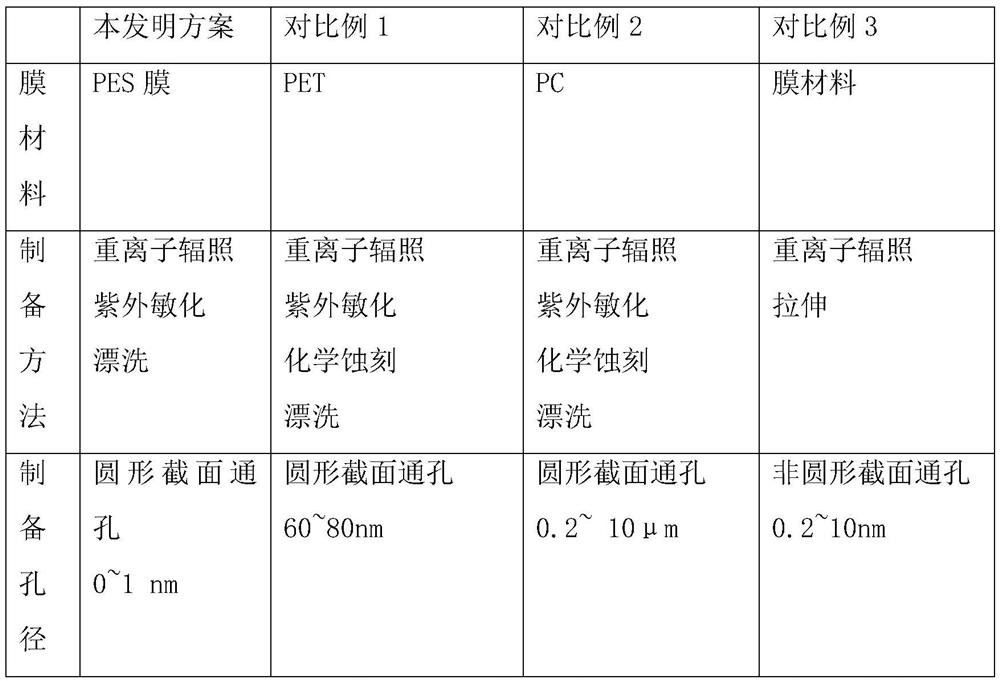

A sub-nanometer, pore size technology, applied in the field of materials, can solve the problems of large pore size, complex process and high cost, and achieve the effects of low cost, simple preparation process, good chemical and physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing a subnanometer porous PES membrane, which includes the following steps in sequence:

[0028] (1) Irradiation with heavy ion beams, the PES film is uniformly irradiated with heavy ion beams, and the thickness of the PES film is 25 μm.

[0029] Heavy ions are heavy ions with more than 2 nucleons. In one embodiment, the heavy ion is one of tantalum ions, xenon ions or bismuth ions. The irradiation density is 2×10 10 ions / cm 2 , the heavy ion energy is 13.5MeV / u. This embodiment adopts 181 Ta ions are uniformly irradiated on the PES membrane in a vacuum environment through the Lanzhou Heavy Ion Accelerator, and the heavy ion beam is vertically irradiated on the horizontally placed PES membrane.

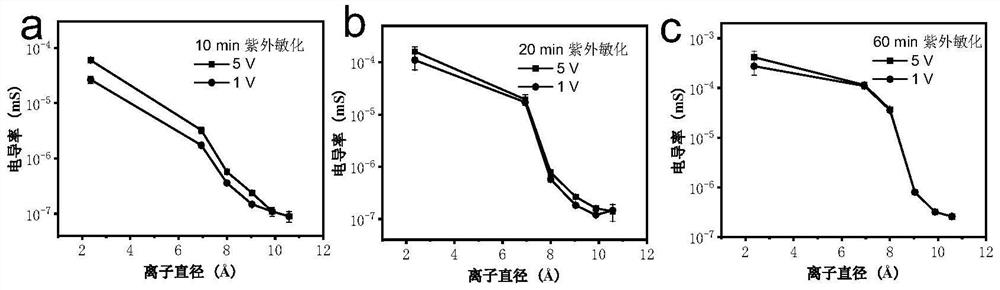

[0030] (2) Ultraviolet light sensitization, using ultraviolet light to sensitize both sides of the PES film, during the sensitization process, the intensity of ultraviolet light remains unchanged.

[0031] UV light sensitization...

Embodiment 2

[0044] This embodiment provides a method for preparing a subnanometer porous PES membrane, which includes the following steps in sequence:

[0045] (1) Irradiation with heavy ion beams. The heavy ion beams are used to uniformly irradiate the PES film, and the thickness of the PES film is 2 μm.

[0046] Heavy ions are heavy ions with more than 2 nucleons. In one embodiment, the heavy ion is one of tantalum ions, xenon ions or bismuth ions. The irradiation density is 1×10 0 ions / cm 2 , the heavy ion energy is 0.1MeV / u. The PES film is uniformly irradiated in a vacuum environment by the Lanzhou Heavy Ion Accelerator, and the heavy ion beam is irradiated vertically to the horizontally placed PES film.

[0047] (2) Ultraviolet light sensitization, using ultraviolet light to sensitize both sides of the PES film, during the sensitization process, the intensity of ultraviolet light remains unchanged.

[0048] UV light sensitization intensity is 35~45mW·cm -2 , UV light sensitizati...

Embodiment 3

[0061] This embodiment provides a method for preparing a subnanometer porous PES membrane, which includes the following steps in sequence:

[0062] (1) Irradiation with heavy ion beams, the PES film is uniformly irradiated with heavy ion beams, and the thickness of the PES film is 100 μm.

[0063] Heavy ions are heavy ions with more than 2 nucleons. In one embodiment, the heavy ion is one of tantalum ions, xenon ions or bismuth ions. The irradiation density is 5×10 11 ions / cm 2 , the heavy ion energy is 100MeV / u. The PES film is uniformly irradiated in a vacuum environment by the Lanzhou Heavy Ion Accelerator, and the heavy ion beam is irradiated vertically to the horizontally placed PES film.

[0064] (2) Ultraviolet light sensitization, using ultraviolet light to sensitize both sides of the PES film, during the sensitization process, the intensity of ultraviolet light remains unchanged.

[0065] UV light sensitization intensity is 35~45mW·cm -2 , UV light sensitization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com