High-thermal-conductivity epoxy VPI resin for high-voltage motor as well as preparation method and application thereof

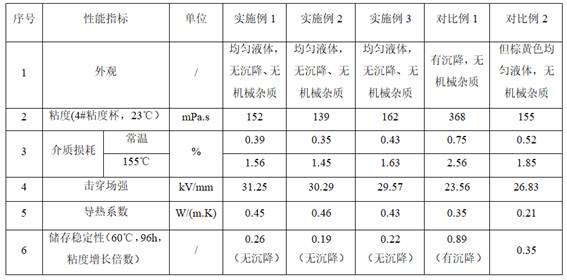

A high-voltage motor and epoxy resin technology, applied in the field of insulating materials for high-voltage motors, can solve the problems of high viscosity of the system, large size of thermally conductive powder, poor thermal conductivity, etc., and achieve high thermal conductivity, low dielectric loss, and breakdown. The effect of high field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] In some preferred embodiments, the preparation method of the modified thermally conductive filler includes the following steps:

[0067] (1) Mix silane coupling agent (KH570), glycidyl alcohol, hydroquinone, stannous chloride or dibutyltin dilaurate, stir evenly, heat up to 140~150°C to react, and the reactants are alcohol-free When the quasi-solvent is distilled out, vacuumize to -0.05~-0.15Mpa, keep warm, keep vacuum and continue to react for 1~2h to obtain the modified resin;

[0068] (2) Mix nano-scale boron nitride, nano-scale alumina and nano-scale silica evenly to prepare a compound mixed powder, dissolve the compound mixed powder in an organic solvent, homogeneously emulsify, grind and disperse to D50<100nm, then mix with the modified resin in step (1) and stannous chloride or dibutyltin dilaurate, and then make the mixed system react at 140~150°C, and the reactant has no alcohol solvent After distillation, the temperature is raised to 170~190°C, and the vacuum...

Embodiment 1

[0080] This embodiment provides a high thermal conductivity epoxy VPI resin for high voltage motors, which is prepared through the following steps:

[0081] Synthesis of modified resin: Add 3500g KH570 into the reaction bottle, add 1749.15g of glycidyl alcohol, 4.20g of stannous chloride and 2.63g of hydroquinone, stir evenly, heat up to 145°C for reaction, and the reactant has no methanol When the solvent is distilled off, evacuate to -0.095MPa, keep warm and keep the vacuum to continue the reaction for 2 hours, and lower to normal temperature to obtain the modified resin.

[0082] Add 500g 60nm boron nitride, 694.5g 35nm alumina, 1583.3g 50nm silicon dioxide into the powder mixer and mix evenly, then transfer the mixed powder to a homogeneous emulsification bottle, add 5158.8g N-methylpyrrolidone , start the homogeneous emulsifier, control the speed at 5000r / min, emulsify uniformly for 2 hours, transfer the material to the grinder, grind and disperse until D50<100nm. Add th...

Embodiment 2

[0086] This embodiment provides a high thermal conductivity epoxy VPI resin for high voltage motors, which is prepared through the following steps:

[0087] The surface-modified thermally conductive filler prepared in Example 1 was used.

[0088] Add 860g of 431 epoxy resin into the reaction bottle, raise the temperature to 116°C, add 74.14g of aluminum acetylacetonate and 59.31g of zinc isooctanoate, stir and dissolve evenly, and immediately cool down to below 45°C, add 148.28g of JF-956 polyesterimide Resin, 1215.86g of diethylene glycol dimethacrylate, 20.76g of 983 dispersant, 2.07g of TBC, 8.30g of 5600 defoamer, stirred evenly to obtain matrix resin.

[0089] Add 563.45g of surface-modified thermally conductive fillers to the above matrix resin, emulsify and disperse for 2 hours at a speed of 8300r / min on a homogeneous emulsifier, and then transfer the material to a grinder (the jacket needs to be cooled by cooling water during the grinding process to control the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com