Solvent-free anti-corrosion high-temperature-resistant coating and preparation method thereof

A high-temperature-resistant coating and solvent-free technology, applied in anti-corrosion coatings, fire-proof coatings, epoxy resin coatings, etc., can solve the problems of coating film softening, affecting health, performance degradation, etc., to achieve thick film formation and not easy to crack , low shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

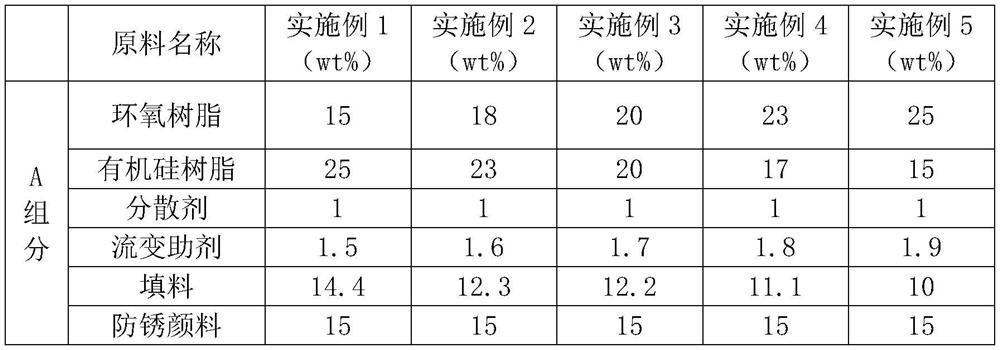

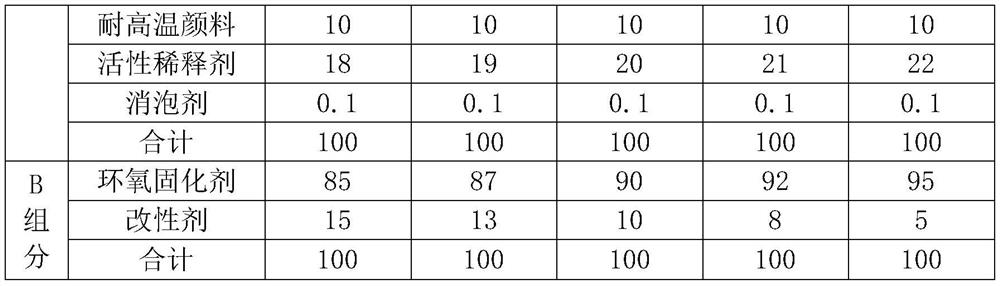

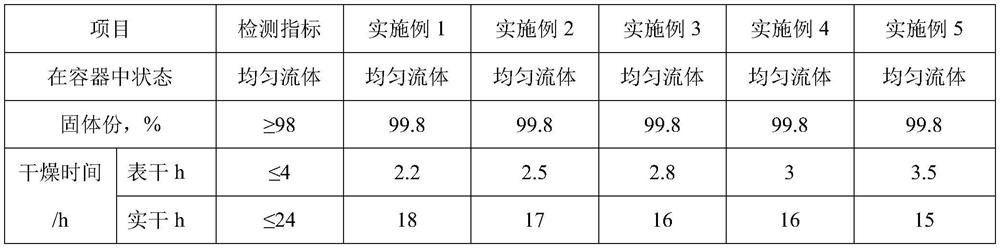

[0035] The composition ratio of the solvent-free anti-corrosion and high-temperature resistant coatings in Examples 1 to 5 is shown in Table 1.

[0036] Table 1

[0037]

[0038]

[0039] The preparation method of the solvent-free anti-corrosion high temperature resistant coating in embodiment 1 to embodiment 5 is as follows:

[0040] ⑴ Preparation method of component A:

[0041] ①. Add the active diluent and dispersant into the dispersing tank in turn according to the formula amount, and stir at a speed of 300-600 rpm for 3-5 minutes until the dispersion is uniform

[0042] ②. Add epoxy resin and silicone resin, stir at 300-600 rpm for 3-5 minutes until evenly dispersed;

[0043] ③. Add rheological additives, fillers, anti-rust pigments, and high-temperature resistant pigments in sequence, and stir at a speed of 800-1000 rpm for 30 minutes until the temperature reaches 50-60°C. Continue to disperse and keep warm for 30 minutes until fine. The degree is less than 80 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com