Soil conditioner based on harmless and resourceful treatment of alkali residue and its preparation

A soil conditioner, a harmless technology, applied in soil conditioning materials, chemical instruments and methods, and other chemical processes, etc., can solve the problem of reducing the activity and mobility of heavy metal ions, limited consumption of alkali residues, and easy reuse of heavy metals. Activation and other issues, to achieve the effect of achieving harmlessness and resource utilization, significant ecological and environmental benefits and economic benefits, and improving the ability to retain water and fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

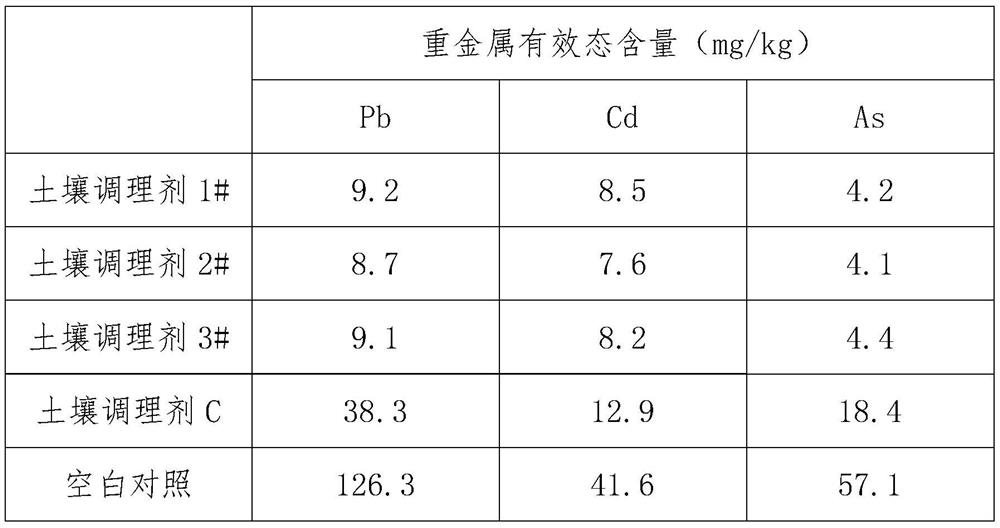

Examples

Embodiment 1

[0033] S1. Water leaching dechlorination

[0034] The alkali residue is pulverized, sieved with 100 meshes, then added to water in a mass ratio of 1:3, and subjected to water immersion treatment at 40° C. under stirring conditions for 30 minutes, stopped stirring and allowed to stand for 20 minutes and then filtered to obtain dechlorinated alkali residue;

[0035] S2. Ultrasonic activation

[0036] The dechlorination alkali residue and the aqueous solution with the EDTA-2Na concentration of 0.3M are mixed and prepared into a slurry at a mass ratio of 1:4, and then ultrasonically treated for 12 minutes after stirring and mixing. The ultrasonic treatment power is 540W, and the frequency is 80KHz;

[0037] S3. Hydrothermal treatment

[0038] Weigh rhamnolipid and SDS in a mass ratio of 3:1, add them into water containing 10% ethanol to dissolve, and form a solution with a total surfactant concentration of 0.5wt%;

[0039] Take the above solution, mix it with the sonicated slurr...

Embodiment 2

[0043] S1. Water leaching dechlorination

[0044] With embodiment 1;

[0045] S2. Ultrasonic activation

[0046] The dechlorination alkali residue and the aqueous solution with EDTA-2Na concentration of 0.3M are mixed and prepared into a slurry at a mass ratio of 1:4, and after stirring and mixing evenly, ultrasonically treated for 15 minutes, the power of ultrasonic treatment is 400W, and the frequency is 80KHz;

[0047] S3. Hydrothermal treatment

[0048] Weigh rhamnolipid and SDS in a mass ratio of 3.3:1, add them into water containing 8% ethanol to dissolve, and form a solution with a total surfactant concentration of 0.5wt%;

[0049] Take the above solution, mix it with the sonicated slurry in step (2) at a volume ratio of 3:1, stir evenly, transfer it into an autoclave, fill 80% of the volume, and react at 130° C. for 7 hours after sealing. ;

[0050] S4. Post-processing

[0051]The reacted autoclave was cooled to room temperature, filtered, washed with water three ...

Embodiment 3

[0053] S1. Water leaching dechlorination

[0054] With embodiment 1;

[0055] S2. Ultrasonic activation

[0056] The dechlorination alkali residue and the aqueous solution with the EDTA-2Na concentration of 0.3M are mixed and prepared into a slurry at a mass ratio of 1:4, and then ultrasonically treated for 20 minutes after stirring and mixing, and the power of the ultrasonic treatment is 200W and the frequency is 60KHz;

[0057] S3. Hydrothermal treatment

[0058] Weigh rhamnolipid and SDS in a mass ratio of 4:1, add them into water containing 5% ethanol to dissolve, and form a solution with a total surfactant concentration of 0.5wt%;

[0059] Take the above solution, mix it with the sonicated slurry in step (2) at a volume ratio of 3:1, stir evenly, transfer it into an autoclave, fill 80% of the volume, and react at 140° C. for 6 hours after sealing. ;

[0060] S4. Post-processing

[0061] The reacted autoclave was cooled to room temperature, filtered, washed with water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com