Grain refinement method for GH4169 high-temperature alloy plate

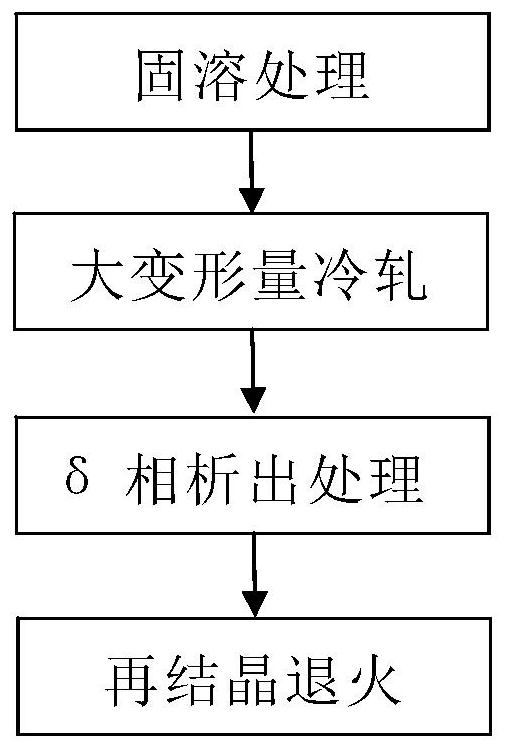

A GH4169, superalloy technology, applied in metal rolling, furnace, heat treatment equipment and other directions, can solve problems such as unfavorable industrialized mass production, complex process flow, low production efficiency, etc., and achieve short heat treatment time, simple process flow, and production efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

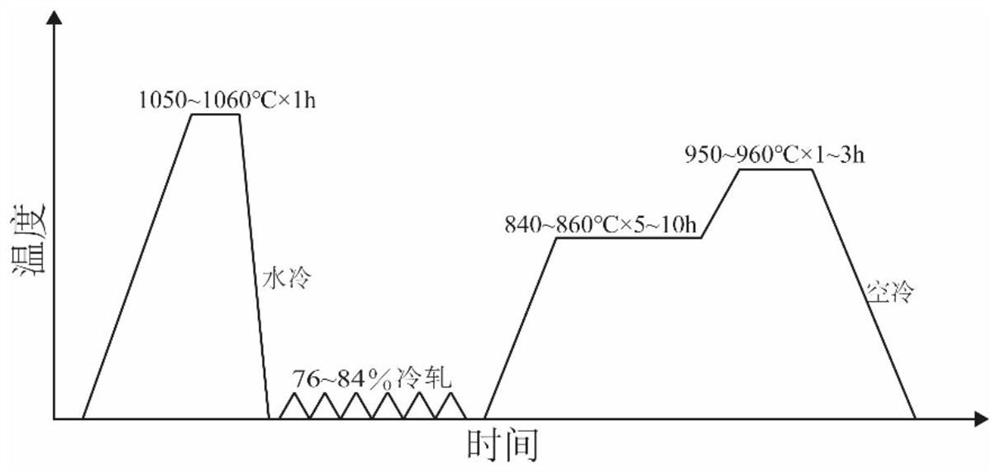

[0040] Solution treatment: The treatment temperature is 1060°C, the holding time is 1h, and water cooling.

[0041] Large deformation cold rolling: the reduction rate of cold rolling is 84%; the reduction per pass is 0.3mm.

[0042] δ phase precipitation treatment: the treatment temperature is 860°C, and the holding time is 10h.

[0043]Temperature rise: the heating rate is 10°C / min.

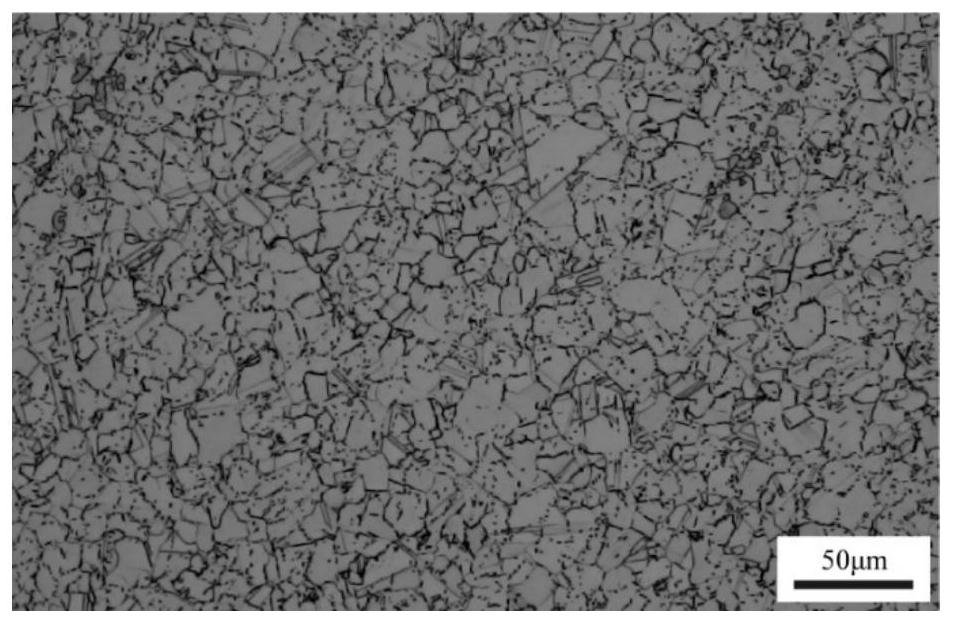

[0044] Recrystallization annealing: the annealing temperature is 950°C; the holding time is 3h, air cooling. The microstructure of the alloy plate finally obtained in this embodiment is as follows: Figure 4 shown. From Figure 4 It can be seen that the microstructure of the alloy sheet obtained in this example is fine and uniform, the average grain size is less than 3 μm, and the grain size rating is ASTM13.5.

Embodiment 2

[0046] Solution treatment: The treatment temperature is 1050°C, the holding time is 1h, and water-cooled.

[0047] Large deformation cold rolling: the reduction rate of cold rolling is 76%; the reduction per pass is 0.3mm.

[0048] δ phase precipitation treatment: the treatment temperature is 860°C, and the holding time is 10h.

[0049] Temperature rise: the heating rate is 10°C / min.

[0050] Recrystallization annealing: the annealing temperature is 950°C; the holding time is 3h, air cooling. The microstructure of the alloy plate finally obtained in this embodiment is as follows: Figure 5 shown. From Figure 5 It can be seen that the microstructure of the alloy plate obtained in this example is fine and uniform, the average grain size is less than 3 μm, and the grain size rating is ASTM14.5.

Embodiment 3

[0052] Solution treatment: The treatment temperature is 1050°C, the holding time is 1h, and water-cooled.

[0053] Large deformation cold rolling: the reduction rate of cold rolling is 84%; the reduction per pass is 0.3mm.

[0054] δ phase precipitation treatment: the treatment temperature is 840°C, and the holding time is 5h.

[0055] Temperature rise: the heating rate is 10°C / min.

[0056] Recrystallization annealing: the annealing temperature is 950°C; the holding time is 3h, air cooling. The microstructure of the alloy plate finally obtained in this embodiment is as follows: Figure 6 shown. From Figure 6 It can be seen that the microstructure of the alloy plate obtained in this example is fine and uniform, the average grain size is less than 3 μm, and the grain size rating is ASTM14.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com