High-performance Sb-based sodium ion battery negative electrode material as well as preparation method and application thereof

A sodium-ion battery and negative electrode material technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem of difficult to achieve a uniform pore structure in the regulation and control reaction, and achieve the effect of good industrialization prospects, simple operation process, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

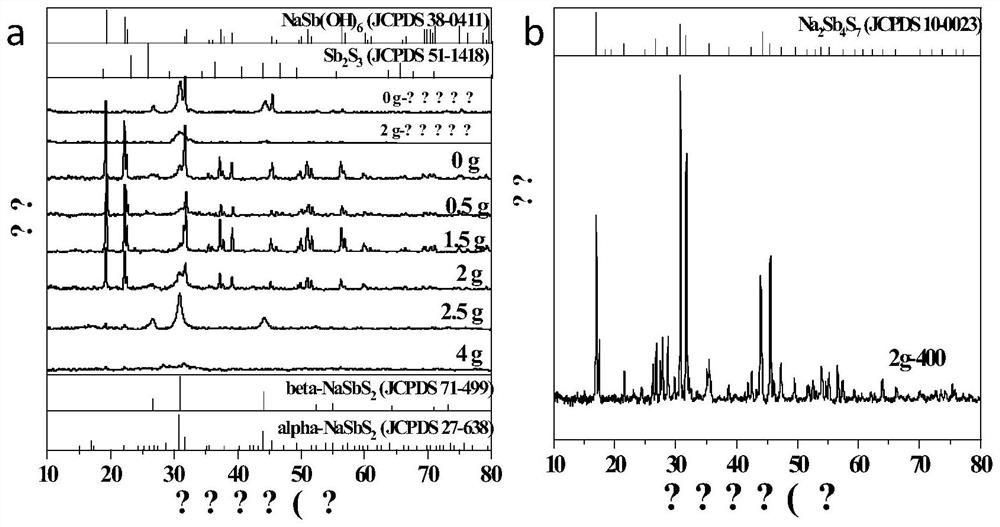

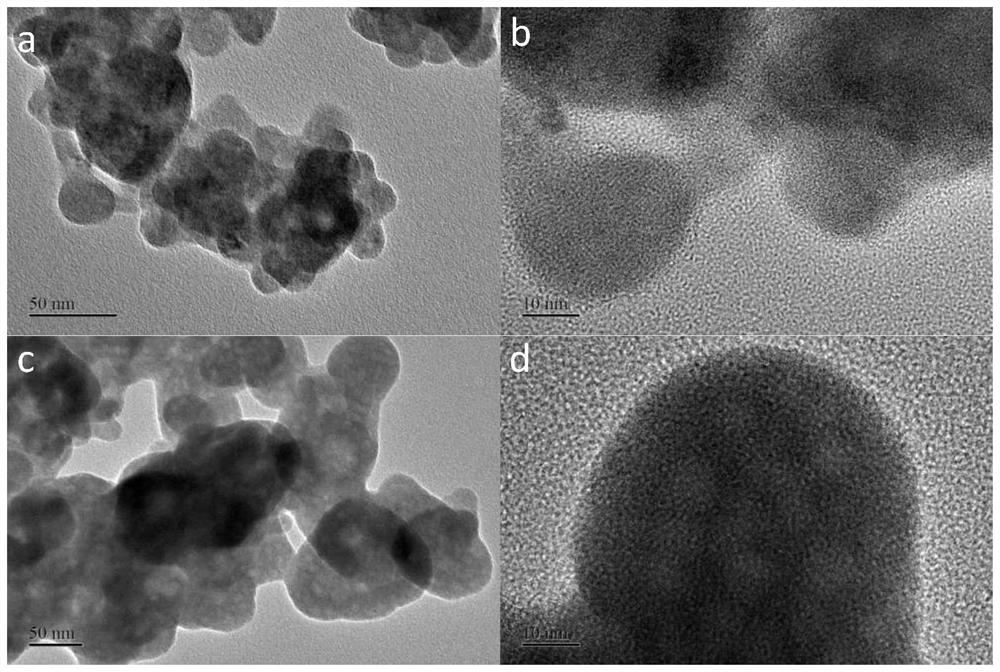

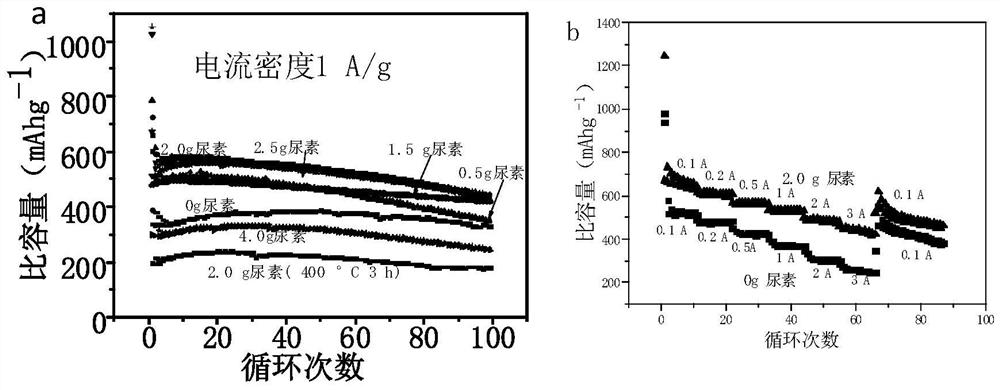

[0025] A high-performance Sb-based sodium-ion battery negative electrode material is NaSb(OH) 6 -NaSbS 2 Porous composite ball, diameter 50nm, specific surface area 150m 2 / g.

[0026] 0.228g SbCl 3 Dissolve in a 20ml ethanol beaker, then ultrasonically stir to dissolve and record it as solution A; take 0.6g of sodium sulfide nonahydrate and dissolve it in a 20ml ethanol beaker and ultrasonically stir and dissolve it as solution B; then drop B solution into A solution , and then add 1.5g of urea into the mixed solution, magnetically stir at room temperature for 1h, and finally pour it into a 50ml reaction kettle, and finally carry out 140°C hydrothermal heating in a constant temperature box for 10h. After the reaction, the obtained material was centrifuged three times with deionized water and absolute ethanol respectively, and the black powder was dried in a drying oven at 70°C for 12 hours, and finally samples were collected for future use.

[0027] After fully grinding t...

Embodiment 2

[0029] A high-performance Sb-based sodium-ion battery negative electrode material is NaSb(OH) 6 -NaSbS 2 Porous composite ball, diameter 75nm, specific surface area 250m 2 / g.

[0030] Dissolve 0.307g of antimony nitrate in a beaker filled with 20ml ethanol, and then carry out ultrasonic stirring and dissolving, and record it as solution A; take 0.6g sodium sulfide nonahydrate, dissolve it in a 20ml ethanol beaker, and dissolve it with ultrasonic stirring, and record it as solution B; into solution A, then add 2.5g of urea into the mixed solution, stir magnetically at room temperature for 1h, and finally pour into a 50ml reaction kettle, and finally carry out 180°C hydrothermal heating in a constant temperature box for 10h. After the reaction, the obtained material was centrifuged three times with deionized water and absolute ethanol respectively, and the black powder was dried in a drying oven at 70°C for 12 hours, and finally samples were collected for future use.

[0031...

Embodiment 3

[0033] A high-performance Sb-based sodium-ion battery negative electrode material is NaSb(OH) 6 -NaSbS 2 Porous composite ball, diameter 100nm, specific surface area 350m 2 / g.

[0034] Dissolve 0.193g of sodium antimonate in a 20ml ethanol beaker, and then ultrasonically stir and dissolve it as solution A; take 0.6g of sodium sulfide nonahydrate and dissolve it in a 20ml ethanol beaker and ultrasonically stir it as solution B; Drop into solution A, then add 0.5 g of urea into the mixed solution, stir magnetically at room temperature for 1 h, and finally pour it into a 50 ml reaction kettle, and finally carry out hydrothermal heating at 120° C. for 10 h in a thermostat. After the reaction, the obtained material was centrifuged three times with deionized water and absolute ethanol respectively, and the black powder was dried in a drying oven at 70°C for 12 hours, and finally samples were collected for future use.

[0035]After fully grinding the sintered material, mix it wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com