Zinc sulfide and carbon nanotube covalent coupling composite material and preparation method and application thereof

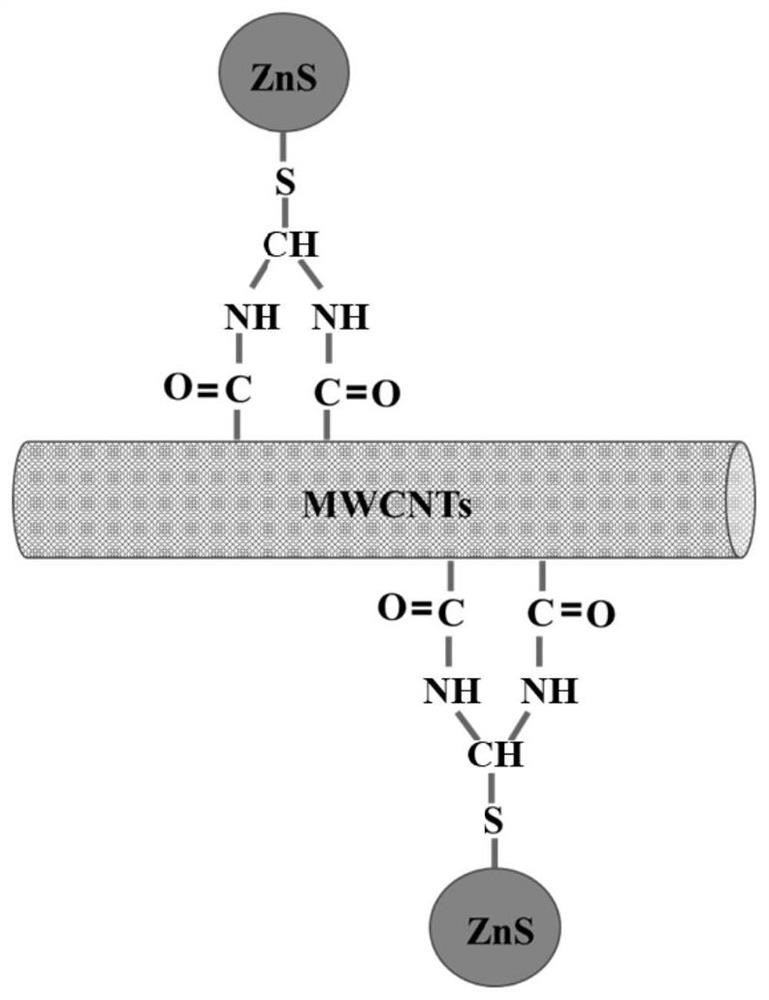

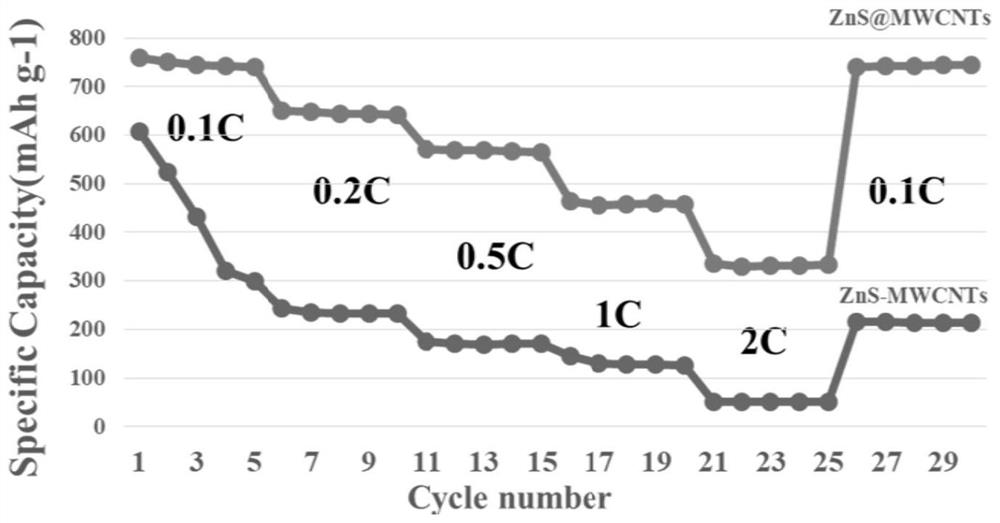

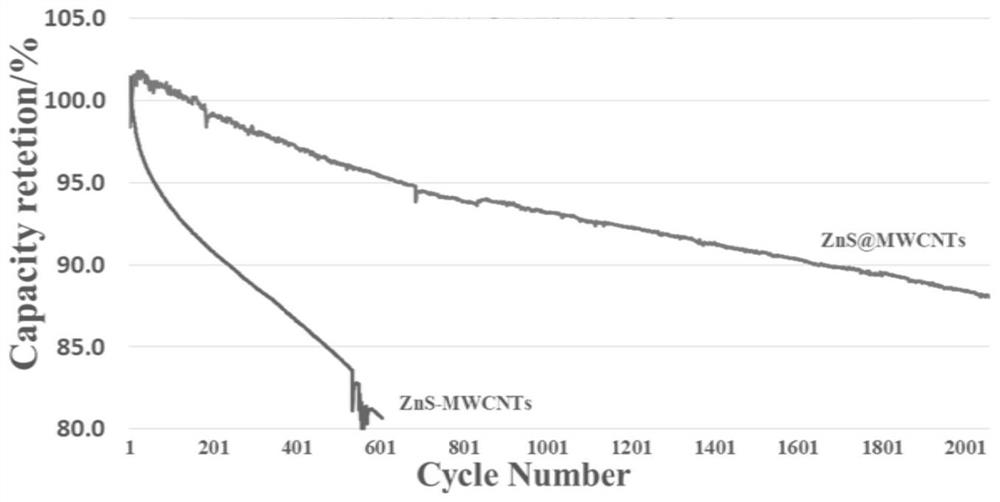

A technology of acidifying carbon nanotubes and carbon nanotubes, which is applied in the direction of zinc sulfide, chemical instruments and methods, carbon compounds, etc., can solve the problems of poor electronic conductivity and ion conductivity of transition metal sulfides, and limit development, and achieve excellent magnification Performance, long-term stability, effect of promoting electron/ion transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing a zinc sulfide and carbon nanotube covalently coupled composite material, comprising the following steps:

[0021] Add 1g of multi-walled carbon nanotubes to a 500ml round bottom flask, then add 250ml of 1M sulfuric acid solution for ultrasonic dispersion, then slowly add 2g of KMnO while stirring 4 powder, stirred for half an hour, heated to 120°C and refluxed for 12 hours to obtain the oxide material;

[0022] At room temperature, add the oxide material into 20ml of 12mol / l concentrated hydrochloric acid, and carry out acidification under stirring conditions for 0.5h to obtain acidified carbon nanotubes, which are washed and dried for later use;

[0023] Ultrasonic disperse 0.1g of dry acidified carbon nanotubes in 100ml of water, add 0.5g of zinc acetate and 0.25g of thiourea in turn, and stir thoroughly for half an hour to obtain a mixed solution; pour the mixed solution into a stainless steel reaction kettle, and then react the stainless stee...

Embodiment 2

[0025] A method for preparing a zinc sulfide and carbon nanotube covalently coupled composite material, comprising the following steps:

[0026] Add 1g of multi-walled carbon nanotubes to a 500ml round bottom flask, then add 250ml of 1M sulfuric acid solution for ultrasonic dispersion, then slowly add 2g of KMnO while stirring 4 powder, stirred for half an hour, heated to 120°C and refluxed for 12 hours to obtain the oxide material;

[0027] At room temperature, add the oxide material into 20ml of 12mol / l concentrated hydrochloric acid, and carry out acidification under stirring conditions for 0.5h to obtain acidified carbon nanotubes, which are washed and dried for later use;

[0028] Ultrasonically disperse 0.1g of dry acidified carbon nanotubes in 100ml of water, add 1g of zinc acetate and 1g of thiourea in turn, stir thoroughly for half an hour to obtain a mixed solution, pour the mixed solution into a stainless steel reaction kettle, and then place the stainless steel rea...

Embodiment 3

[0030] A method for preparing a zinc sulfide and carbon nanotube covalently coupled composite material, comprising the following steps:

[0031] Add 1g of multi-walled carbon nanotubes to a 500ml round bottom flask, then add 250ml of 1M sulfuric acid solution for ultrasonic dispersion, then slowly add 2g of KMnO while stirring 4 powder, stirred for half an hour, heated to 120°C and refluxed for 12 hours to obtain the oxide material;

[0032] At room temperature, add the oxide material into 20ml of 12mol / l concentrated hydrochloric acid, and carry out acidification under stirring conditions for 0.5h to obtain acidified carbon nanotubes, which are washed and dried for later use;

[0033] Ultrasonically disperse 0.1g of dry acidified carbon nanotubes in 100ml of water, add 0.5g of zinc acetate and 15g of thiourea in turn, and stir thoroughly for half an hour to obtain a mixed solution. Pour the mixed solution into a stainless steel reaction kettle, and then put the stainless stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com