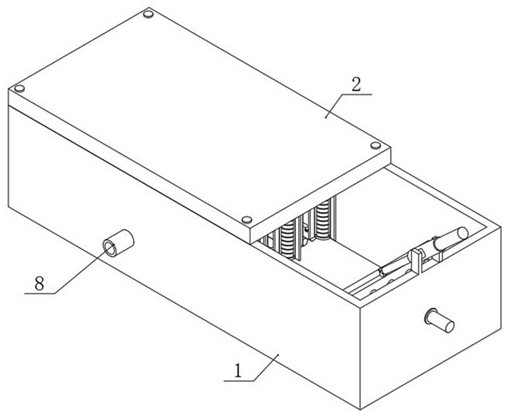

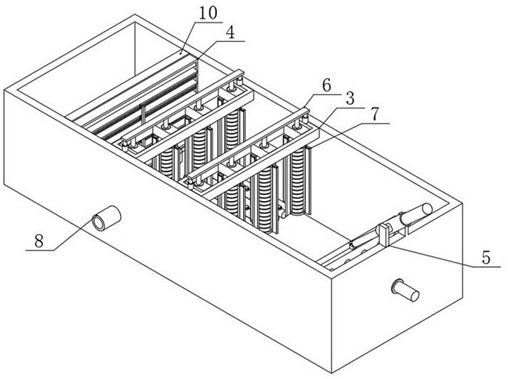

Circulating wastewater treatment device

A wastewater treatment and recycling technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Large area and other problems, to achieve the effect of reducing the reaction distance, improving the processing effect, and reducing the inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

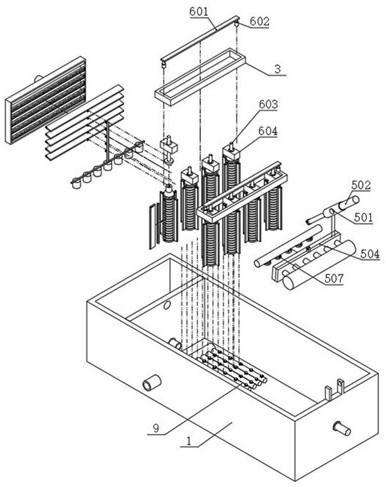

[0043] The implementation method is as follows: when the waste water to be treated enters the pretreatment chamber on the side of the treatment pool through the drainage equipment, the original activated sludge in the pretreatment chamber can reduce the concentration of the waste water and carry out sand removal and precipitation. When the treatment chamber is fed with water again, it enters the reaction chamber on the side of the treatment pool. At this time, the water entering the reaction chamber can abut and contact the surfaces of the spoilers on both sides under the action of the abutment and diversion of the spoiler on the front side, and Under the abutment effect of the lateral spoilers on both sides, the flow velocity of the waste water at the rear side of the transverse spoiler slows down after continuous diversion to the outside of the spoiler, and the waste water after the flow velocity slows down can adhere to the surface of the rear inflatable cover. The activated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com