Synthesis of high-temperature-resistant modified nano aluminum oxide blocking agent and oil-based drilling fluid

A nano-alumina and oil-based drilling fluid technology, which is applied in the field of oil and gas field drilling, can solve problems such as well wall instability, and achieve the effects of enhanced salt resistance, good performance, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

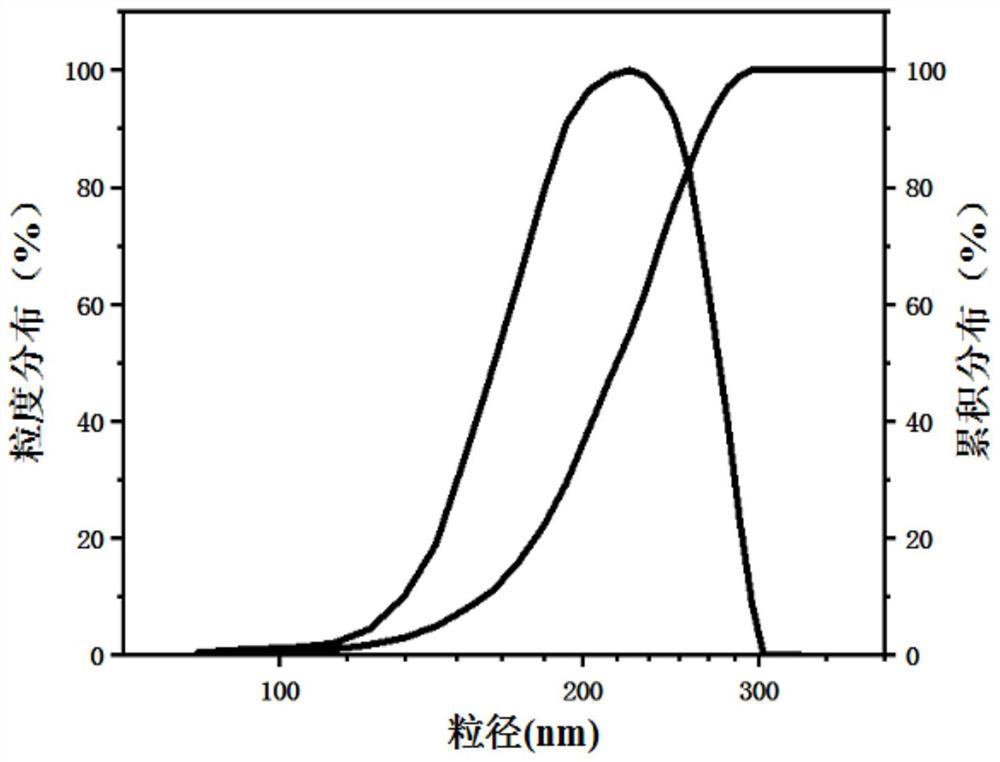

Embodiment 1

[0026] S1. Dry the nano-alumina in a vacuum drying oven at 60°C for 12 hours, accurately weigh 10 g of the dried nano-alumina in a round-bottomed flask, add 200 mL of ethanol and 200 mL of water into the bottle, ultrasonically disperse for 40 minutes, and then add 0.3 g (3-aminopropyl) dimethylethoxysilane, condensed and refluxed for 5 hours, centrifuged at 10000r / min high-speed centrifuge for 10min to obtain a precipitate, washed with ethanol, repeated 4 times, and vacuum-dried for 20h to obtain Nano-alumina modified by silane coupling agent;

[0027] S2. Dissolve 0.1mol of modified nano-alumina in 150ml of toluene, add 0.01mol of 4-chlorostyrene, stir rapidly at 90°C for 4h, cool to room temperature, add ether, distill under reduced pressure, and dry in vacuum for 3h ; Take 0.1 mol of the dried product, add 0.01 mol of FeCl and 0.5 mol of p-vinylbenzylamine, stir and react at 70°C for 24 hours, and distill under reduced pressure to obtain modified nano-alumina containing eth...

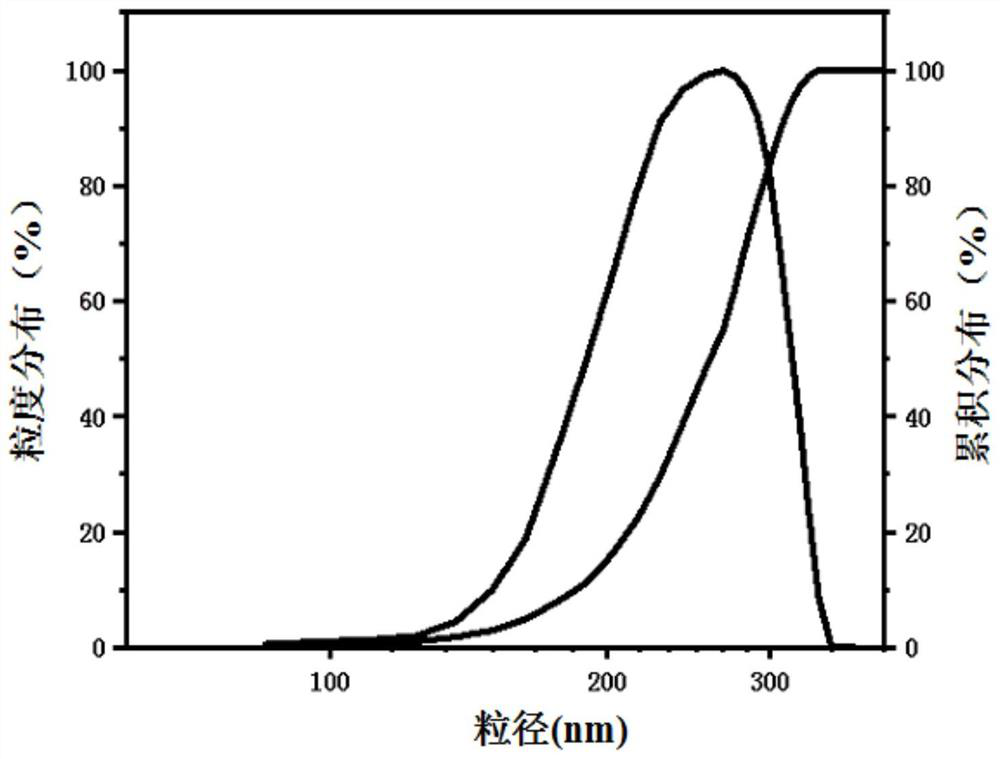

Embodiment 2

[0030] S1. Dry the nano-alumina in a vacuum drying oven at 60°C for 12 hours, accurately weigh 10 g of the dried nano-alumina in a round-bottomed flask, add 200 mL of ethanol and 200 mL of water into the bottle, and ultrasonically disperse for 50 minutes, then add 0.36 gY-Aminopropyldimethylmethoxysilane, condensed and refluxed for 5 hours, centrifuged in a high-speed centrifuge at 10,000r / min for 10 minutes to obtain a precipitate, washed with ethanol, repeated 4 times, and dried in vacuum for 24 hours to obtain a silane coupling Agent-modified nano-alumina;

[0031] S2. Dissolve 0.2mol of modified nano-alumina in 300ml of toluene, add 0.02mol of 2-chlorostyrene, stir rapidly at 100°C for 4h, cool to room temperature, add ether, distill under reduced pressure, and dry in vacuum for 3h ;Take 0.2mol of the dried product, add 0.02mol FeCl and 0.1mol (E)-4-phenyl-3-buten-1-amine, stir and react at 80°C for 20h, and distill under reduced pressure to obtain Modified nano-alumina; ...

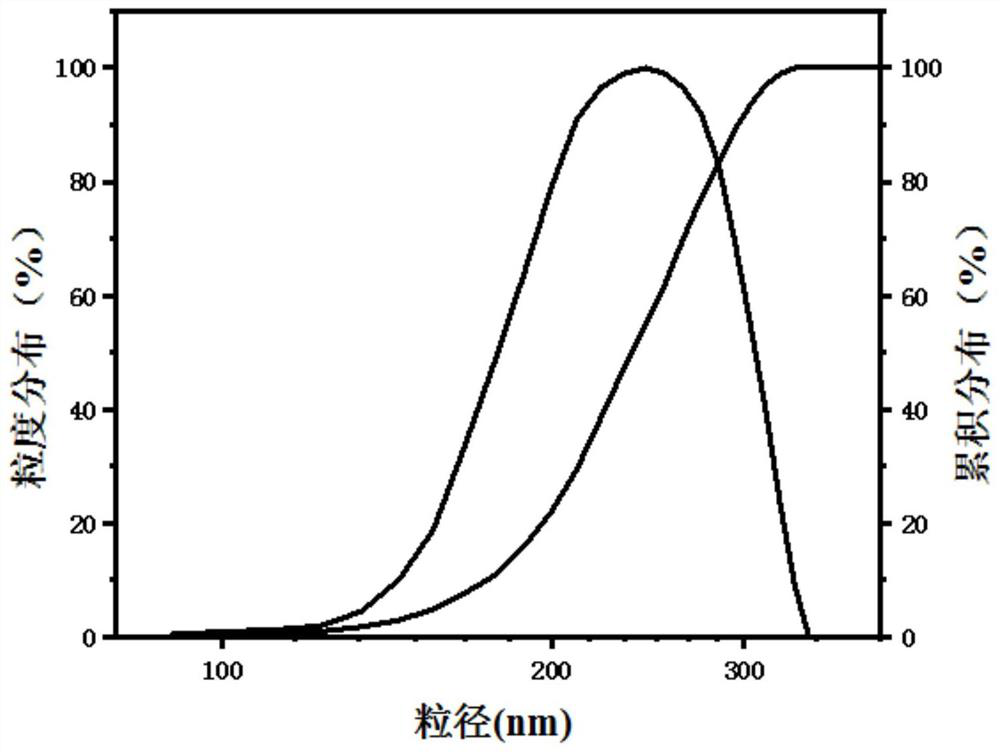

Embodiment 3

[0034] S1. Dry the nano-alumina in a vacuum oven at 70°C for 10 hours, accurately weigh 12g of the dried nano-alumina in a round-bottomed flask, add 200mL of ethanol and 200mL of water into the bottle, ultrasonically disperse for 40min, and then add 0.3 gY-Aminopropyltriethoxysilane, after condensation and reflux reaction for 5 hours, centrifuge at 10,000r / min high-speed centrifuge for 10min to obtain precipitate, wash with ethanol, repeat 5 times, and vacuum dry for 20h to obtain modified silane coupling agent Sexual nano-alumina;

[0035] S2. Dissolve 0.15mol of modified nano-alumina in 230ml of toluene, add 0.02mol of 3-chlorostyrene, stir rapidly at 90°C for 4h, cool to room temperature, add ether, distill under reduced pressure, and dry in vacuum for 3h ;Take 0.15mol of the dried product, add 0.02mol FeCl and 0.75mol (E)-4-phenyl-3-butene-1-amine, stir and react at 70°C for 24h, and distill under reduced pressure to obtain Modified nano-alumina;

[0036] S3. Take 0.15 m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap