Material examination device based on electromagnetic thermal multi-physical field synchronous loading

A technology of multi-physics and electromagnetic repulsion, which is applied in the direction of material analysis, measuring devices, and analysis materials through electromagnetic means, to achieve the effects of uniform loading, reduced spacing, and reliable stress transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

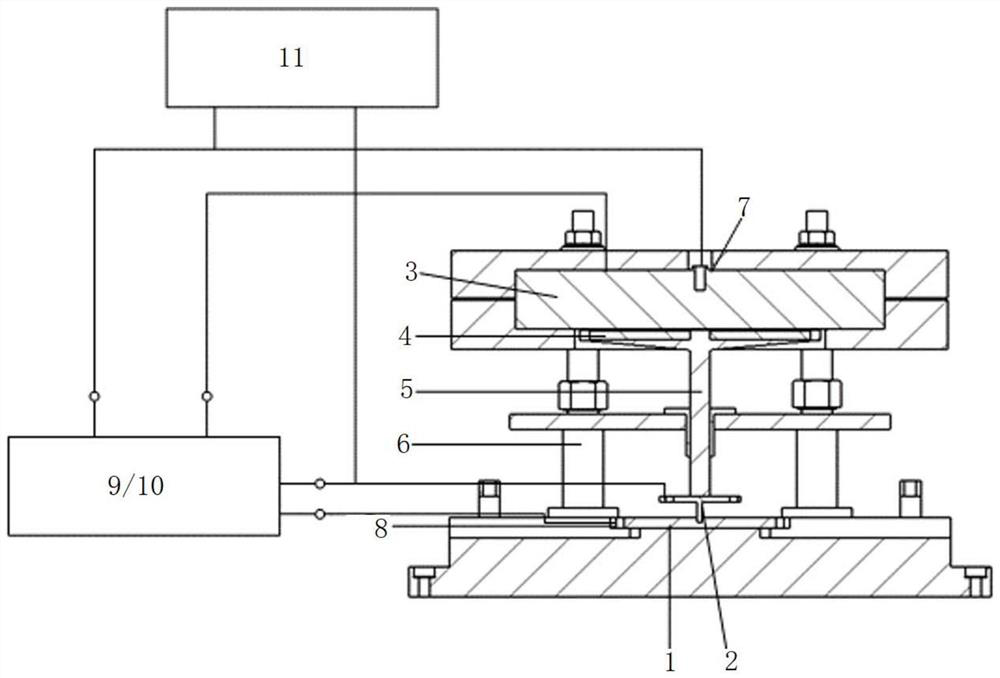

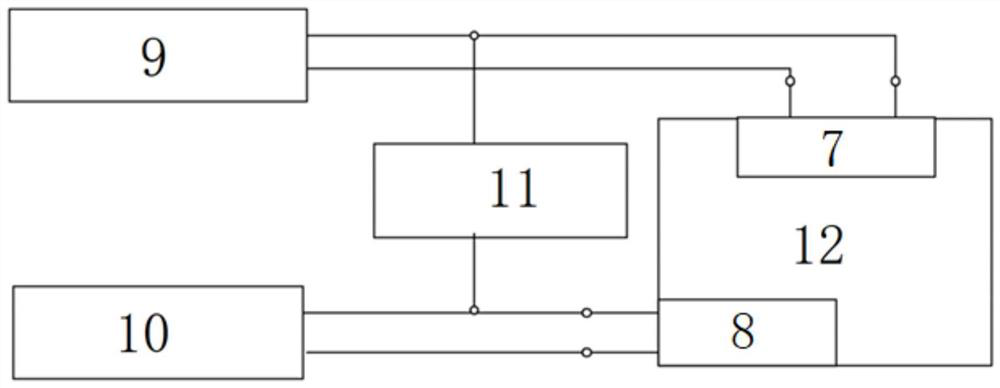

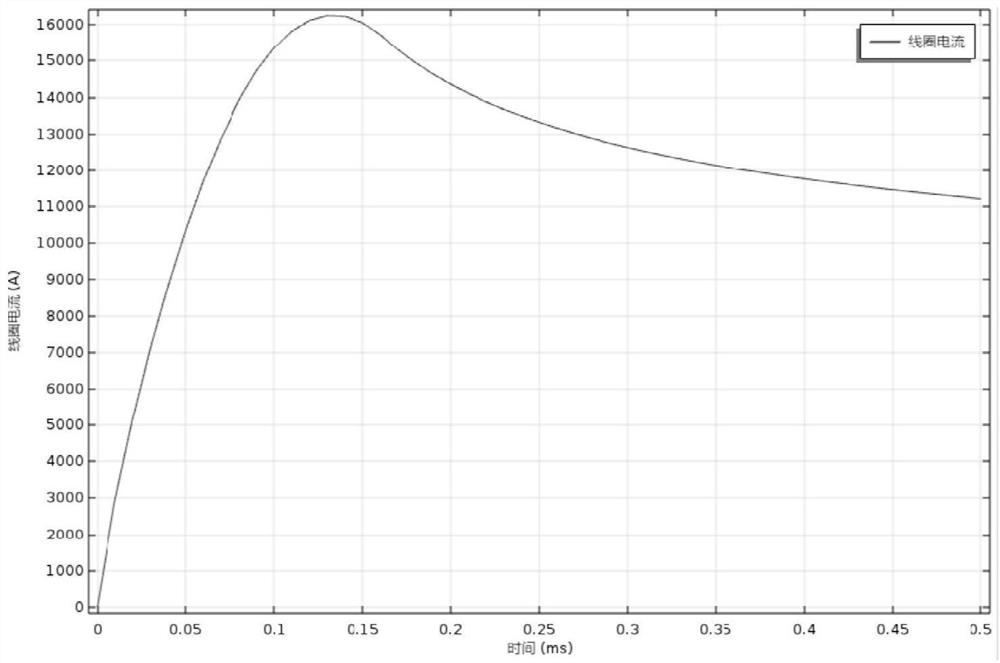

[0060] The power processing unit generates two pulse currents, and the timing of the two pulse currents is controlled by a synchronous trigger device. One of them supplies power to the main circuit. Discharge on a 20mm aluminum sample, the temperature of the sample rises due to ohmic heat, and the temperature rise rate reaches 10 5 ℃ / s; another pulse current supplies power to the electromagnetic repulsion coil circuit, generating a current such as image 3 As shown, the repulsive disk generates electromagnetic force as Figure 4 As shown, the generated stress wave acts downward to the sample with the stress wave amplifier, and an equivalent stress greater than 500 MPa is generated on the sample, which reaches the equivalent condition of strain rate when the material failure occurs in the electromagnetic track.

[0061] During the working process, the power processing unit is decoupled and recombined to form two pulse power modules, and the discharge sequence of the two circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com