Mixing device and coating mixing method for coating method silver tungsten carbide contact

A technology of silver tungsten carbide and mixing devices, which is applied in chemical instruments and methods, mixers, transportation and packaging, etc., and can solve problems such as performance degradation, insufficient uniformity of contact materials, and large particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

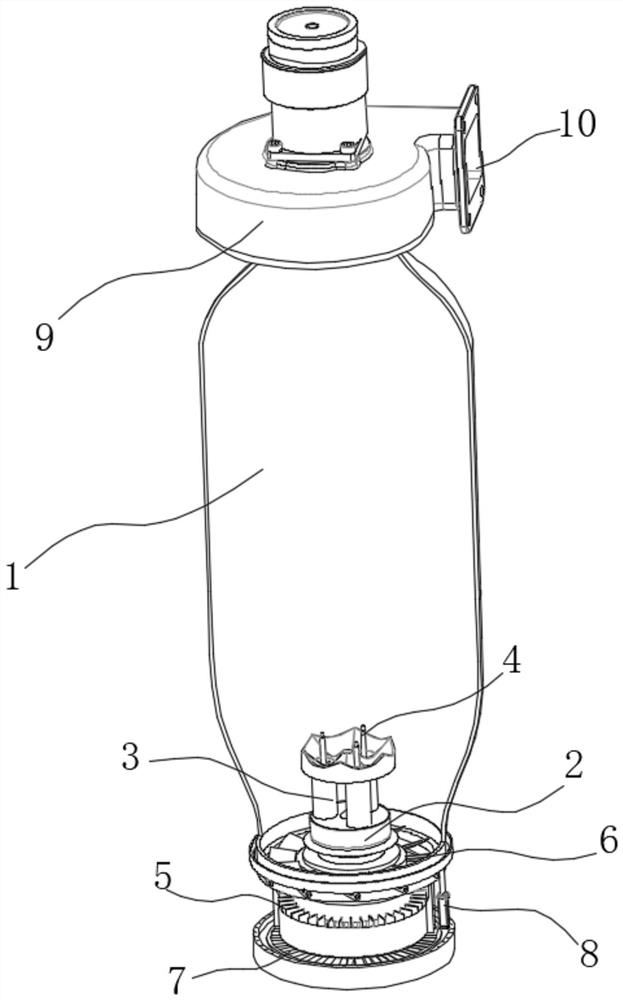

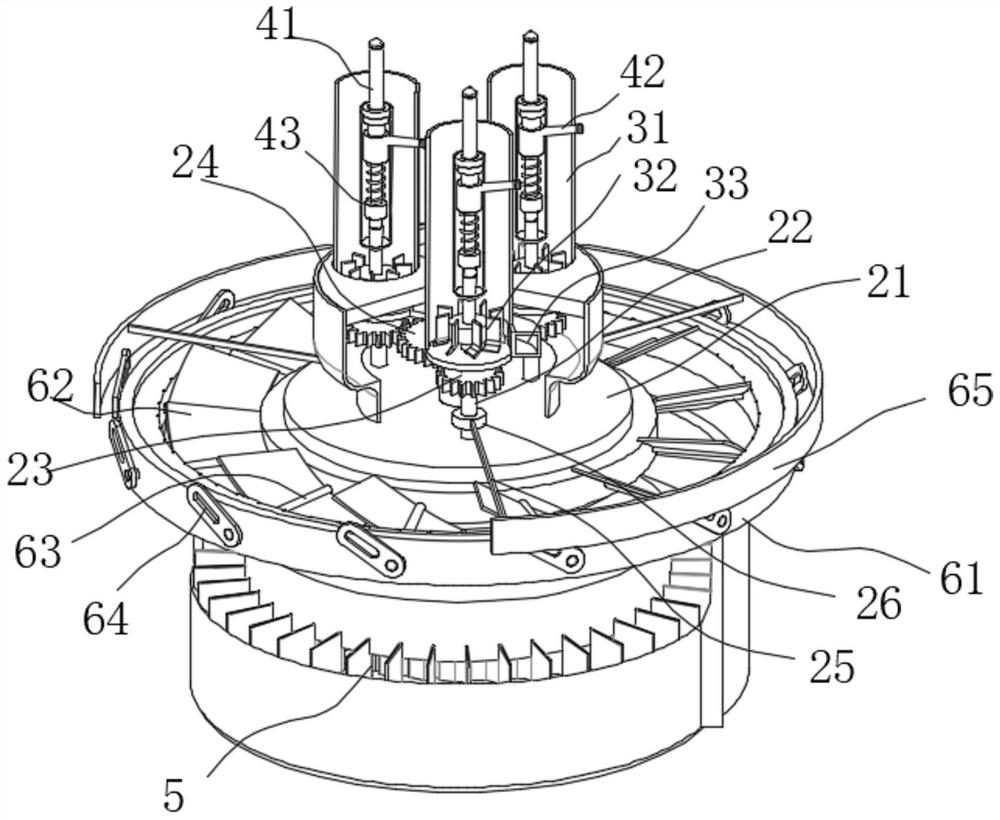

[0047] see figure 1 and figure 2 , in an embodiment of the present invention, a hybrid device for cladding silver tungsten carbide contacts, comprising:

[0048] Mixing cylinder 1, cylindrical container;

[0049] The central column 2 is concentrically fixed at the bottom of the mixing cylinder 1;

[0050] A powder spraying assembly 3, a plurality of said powder spraying assemblies 3 are distributed above the central column 2, and the bottom is connected to the feeding conduit;

[0051] The spray assembly 4 is arranged at the center of each powder spray assembly 3; the fan 5, an annular turbine blade, can be driven by a motor and rotatably set on the periphery of the bottom of the central column 2;

[0052] The grill assembly 6 is arranged in the gap between the central column 2 above the fan 5 and the inner wall of the mixing cylinder 1;

[0053] The base 7 is fixed on the bottom of the mixing cylinder 1 as a support, and it is an overhead structure for ventilating the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com