Preparation method of racomitrium canescens charcoal adsorbent

A biochar and adsorbent technology, applied in carbon preparation/purification, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as high cost, harsh application conditions, and lack of research on other moss species, and achieve improvement The effect of high adsorption capacity and mesoporosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

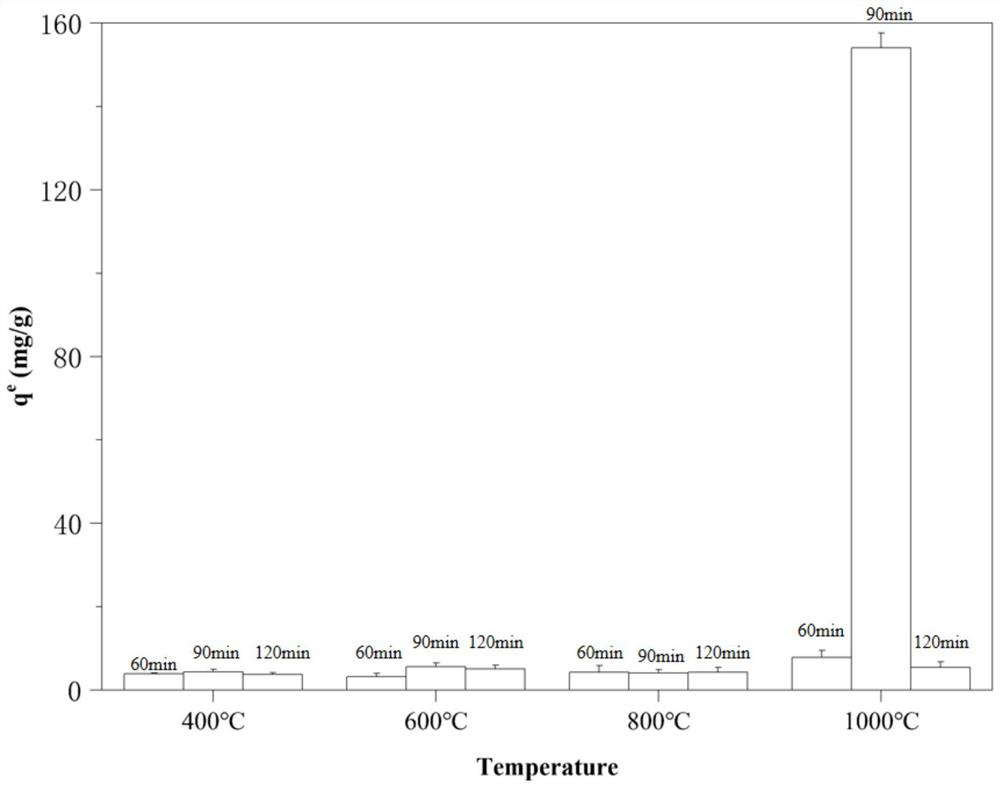

Embodiment 1

[0041] Preparation of sand moss biochar, the specific method includes: washing with deionized water to remove dust and impurities of sand moss, drying sand moss at a temperature of 105 ° C for 6 hours, crushing and filtering with a 0.45mm sieve; Fill the ark with 5g sand moss, put it into the tube furnace, and put it in the 60cm 3 The sand moss biochar adsorbent was prepared by constant temperature heating under constant nitrogen flow conditions, wherein the constant temperature heating temperature was 400 ° C, and the heating time was 60 min.

Embodiment 2

[0043] Preparation of sand moss biochar, the specific method includes: washing with deionized water to remove dust and impurities of sand moss, drying sand moss at a temperature of 105 ° C for 6 hours, crushing and filtering with a 0.45mm sieve; Fill the ark with 5g sand moss, put it into the tube furnace, and put it in the 60cm 3 The sand moss biochar adsorbent was prepared by constant temperature heating under constant nitrogen flow conditions, wherein the constant temperature heating temperature was 400 ° C, and the heating time was 90 min.

Embodiment 3

[0045] Preparation of sand moss biochar, the specific method includes: washing with deionized water to remove dust and impurities of sand moss, drying sand moss at a temperature of 105 ° C for 6 hours, crushing and filtering with a 0.45mm sieve; Fill the ark with 5g sand moss, put it into the tube furnace, and put it in the 60cm 3 The sand moss biochar adsorbent was prepared by constant temperature heating under the condition of continuous nitrogen flow rate per min, wherein the constant temperature heating temperature was 400°C and the heating time was 120min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com