Knife stone and preparation method thereof

A technology of whetstone and granular materials, which is applied in the direction of grinding/polishing equipment, grinding devices, manufacturing tools, etc., and can solve the problem that chromium products are difficult to have the function of a whetstone, have poor mechanical impact resistance, and reduce the concentration of chromium oxide. And other problems, to achieve the effect of enhanced wear resistance, good mechanical shock resistance and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

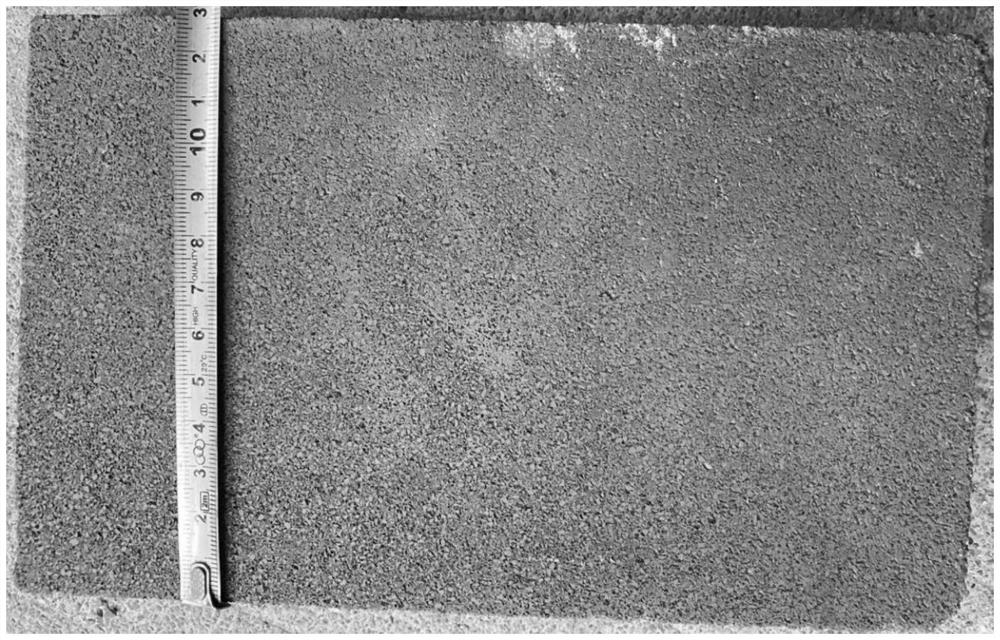

Image

Examples

preparation example Construction

[0065] The present invention also provides a kind of preparation method of above-mentioned whetstone, comprises the following steps:

[0066] Mixing the raw materials of the powder to prepare the powder;

[0067] Mixing the raw materials of the first granular material, the second granular material and the third granular material respectively to prepare the first granular material, the second granular material and the third granular material;

[0068] mixing the first granular material, the second granular material, and the third granular material with a liquid binder to prepare wet granular material;

[0069] The wet granules are mixed with the powder, then shaped for the second time and heat-treated for the second time.

[0070] In a specific example, isostatic pressing or machine pressing is used for the first molding.

[0071] More specifically, the pressure of isostatic pressing is 180MPa-200MPa. Isostatic pressing will finally obtain an average density of 4.9g / cm 3 Th...

Embodiment 1

[0081] The present embodiment provides a kind of whetstone and preparation method thereof, specifically as follows:

[0082] (1) Preparation of pellets

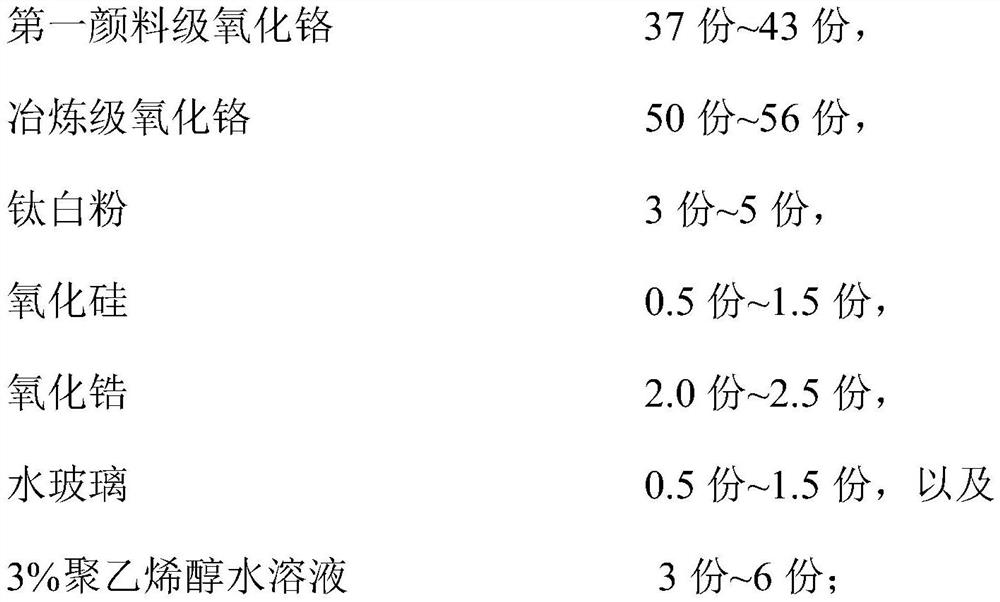

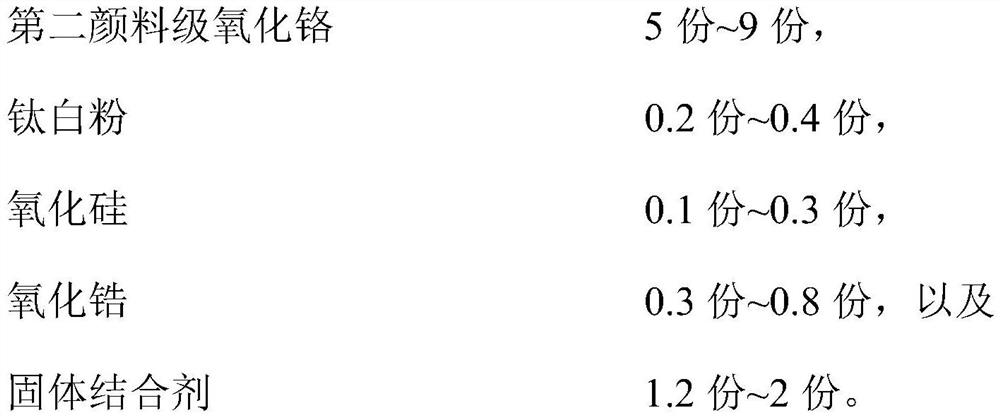

[0083] In terms of parts by weight, after the following raw materials are fully mixed, the material is discharged to be formed:

[0084]

[0085] Isostatic pressing 200MPa;

[0086] After molding, send it to a reducing atmosphere for firing at 1630°C for 8 hours;

[0087] broken after firing.

[0088] (2) Preparation of the first granular material, the second granular material and the third granular material

[0089] The granular material is passed through a 20-mesh sieve and a 40-mesh sieve, and the 40-mesh sieve is used to prepare the first granular material;

[0090] The granular material is passed through a 40 mesh sieve and a 60 mesh sieve, and the 60 mesh sieve is used to prepare the second granular material;

[0091] Pass the granular material through a 60-mesh sieve and a 100-mesh sieve, and take the 100-mesh ...

Embodiment 2

[0106] The present embodiment provides a kind of whetstone and preparation method thereof, specifically as follows:

[0107] (1) Preparation of pellets

[0108] In terms of parts by weight, after the following raw materials are fully mixed, the material is discharged to be formed:

[0109]

[0110] Isostatic pressing 200MPa;

[0111] After molding, send it to a reducing atmosphere for firing at 1630°C for 8 hours;

[0112] broken after firing.

[0113] (2) Preparation of the first granular material, the second granular material and the third granular material

[0114] Pass the granular material through a 20-mesh sieve and a 30-mesh sieve, and then feed through a 30-mesh sieve to prepare the first granular material;

[0115] The granular material is passed through a 40 mesh sieve and a 60 mesh sieve, and the 60 mesh sieve is used to prepare the second granular material;

[0116] Pass the granular material through a 60-mesh sieve and a 100-mesh sieve, and take the 100-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com