Method for improving wear resistance of surface of connector pin

A connector, wear-resistant technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of low reliability of electrical contact, poor bonding force of gold plating, high porosity, etc., and achieve excellent Excellent electrical contact performance and wear resistance, excellent coating performance, and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

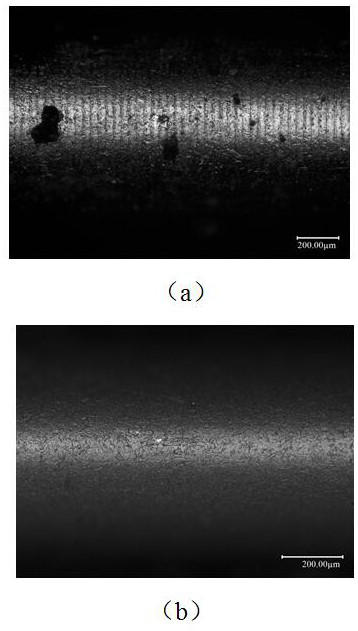

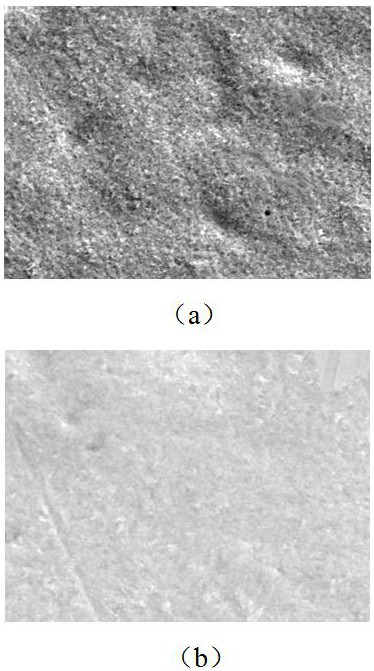

Embodiment 1

[0022] This embodiment provides a method for improving the wear resistance of the connector pin surface. The acetone and absolute ethanol used are commercially available analytical grade reagents, and the purity of the copper target, nickel target, and gold target are all 99.99%. %. Specifically include the following steps:

[0023] Step (1) First select the pins of wire spring wire connectors as the base material, and the pins are pure copper pins. Put the base into acetone and ultrasonically clean it for 10 minutes, rinse it with deionized water, and then dry it. The dried substrate was ultrasonically cleaned in absolute ethanol for 10 minutes, washed with deionized water and then dried;

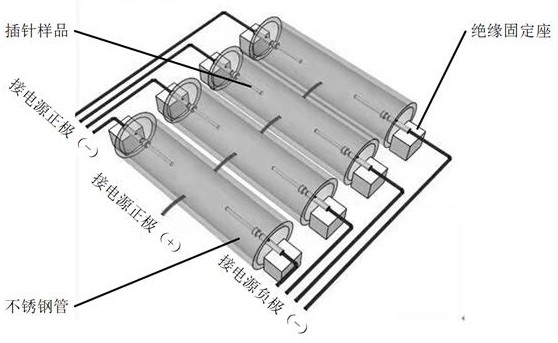

[0024] Step (2) Put the pretreated substrate into the vacuum chamber and coat the stainless steel tube, connect a DC power supply for glow cleaning, wherein, the working conditions of the DC glow cleaning are: the substrate is used as the negative electrode, the stainless steel tube is us...

Embodiment 2

[0031] This embodiment provides a method for improving the wear resistance of the connector pin surface. The acetone and absolute ethanol used are commercially available analytical grade reagents, and the purity of the copper target, nickel target, and gold target are all 99.99%. %. Specifically include the following steps:

[0032] Step (1) First select the pin of the wire spring wire connector as the base material, and the pin is beryllium bronze (QeB 2 ) into the needle, put the substrate into acetone for 10 minutes of ultrasonic cleaning, rinse with deionized water and dry, put the dried substrate into absolute ethanol for 10 minutes of ultrasonic cleaning, wash with deionized water and then dry;

[0033] Step (2) Put the pretreated substrate into the vacuum chamber and coat the stainless steel tube, connect a DC power supply for glow cleaning, wherein, the working conditions of the DC glow cleaning are: the substrate is used as the negative electrode, the stainless steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com