Silicon carbide consubstantial PIN (Personal Identification Number) microstructure material and preparation method thereof

A manufacturing method and technology of silicon carbide, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to achieve the effects of improving switching speed, high power density, and bright surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

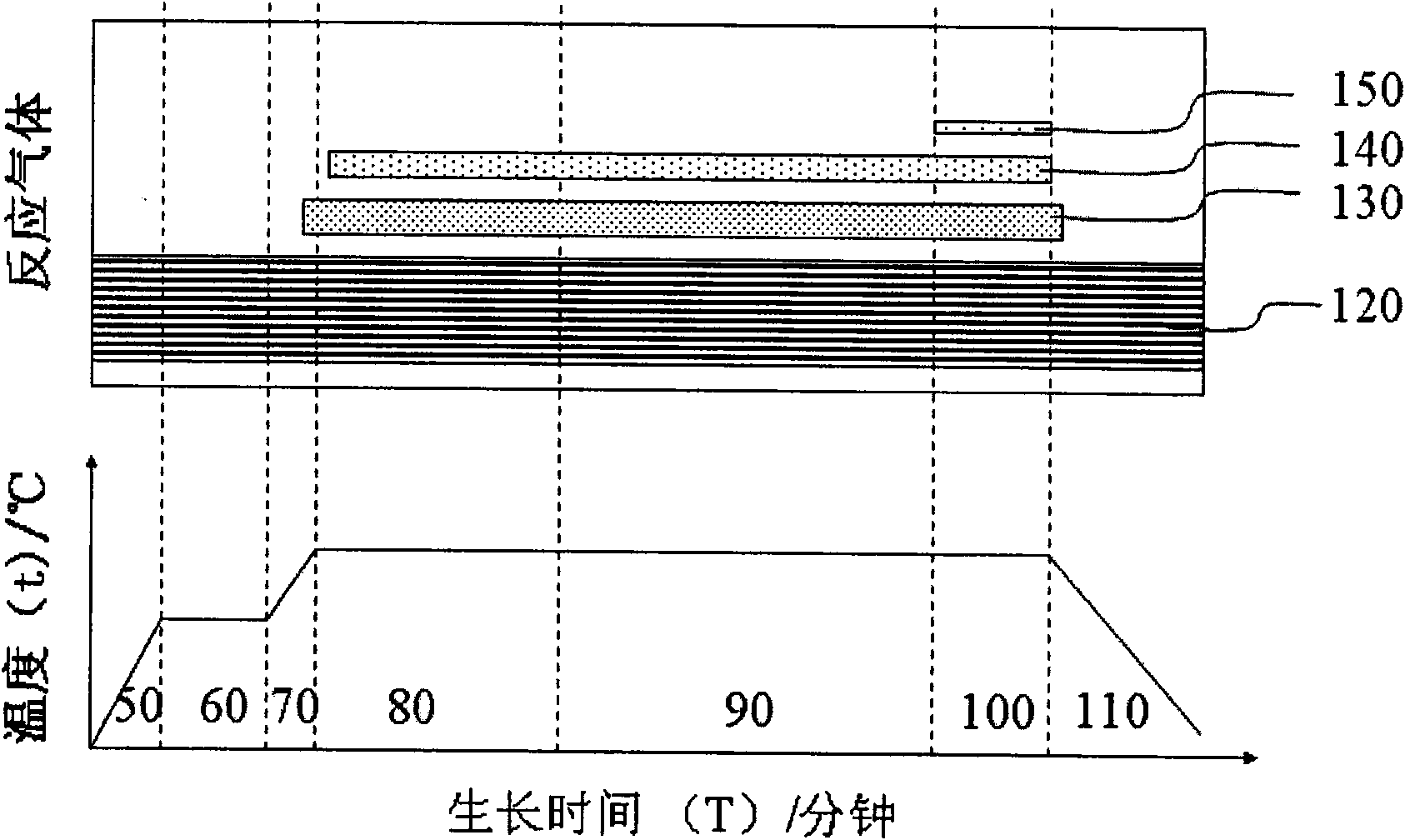

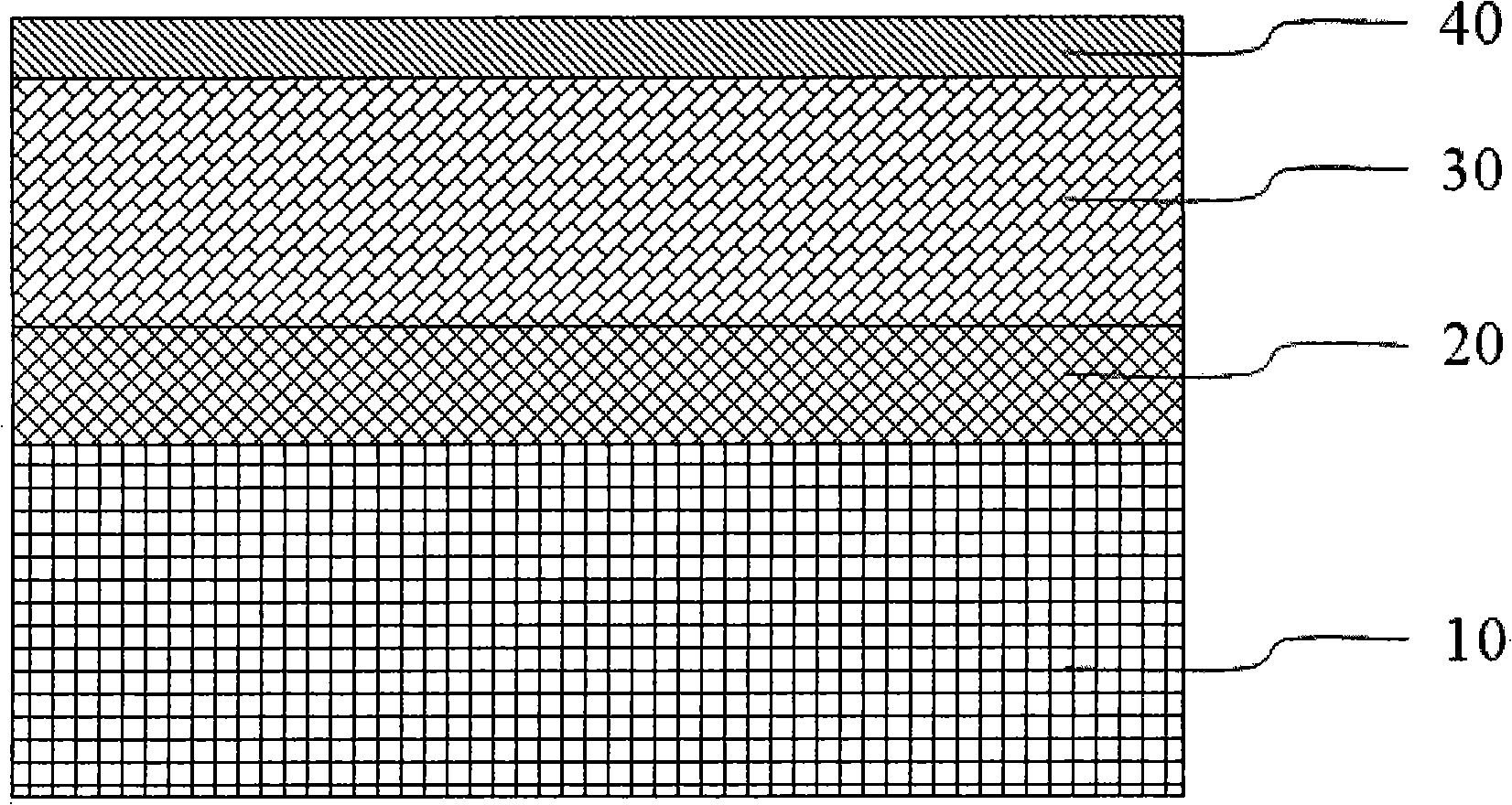

[0048] A single crystal 4H-SiC substrate is used, and its Si(0001) surface is 8° away from the direction. After chemical polishing, it is cleaned and placed in a low-pressure chemical vapor deposition equipment. Hydrogen gas is introduced to maintain a pressure of 40 Torr. , heat up to 1350° C. and keep it warm, etch and polish the surface of the substrate with hydrogen gas for 30 minutes. Then raise the temperature to 1500°C at a rate of 40°C / min, feed ethylene at a flow rate of 1 sccm, and when the substrate surface is heated to 1550°C, feed silane with a flow rate of 1 sccm, keep the temperature constant, grow for 180 minutes, and complete the buffer layer and the growth of the intrinsic layer. Keep the growth conditions unchanged, and carry out the P + Cap growth, time 3 minutes. Turn off borane, silane and ethylene in turn, and cool down naturally under a hydrogen atmosphere. The pressure was maintained at 40 Torr throughout the process, and the hydrogen flow rate was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com