Device and method for recovering and purifying flue gas and residual anode waste heat of aluminum discharge ladle

A waste heat recovery and flue gas technology, applied in the field of cleaner production, can solve problems such as unorganized emission pollution, and achieve the effects of energy saving, good working environment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

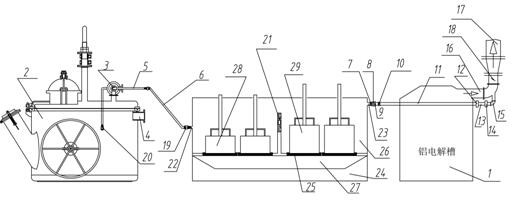

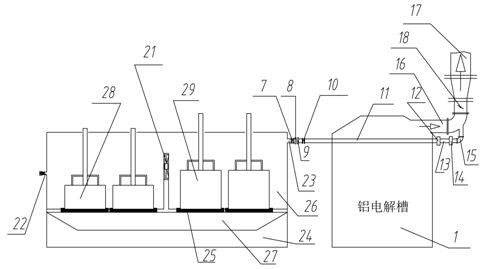

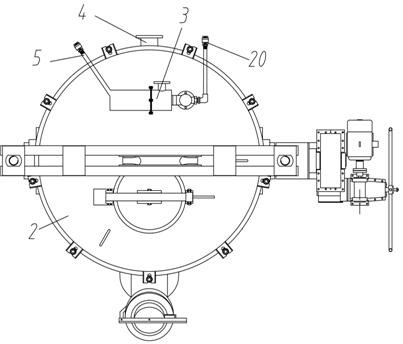

[0023] The device for recovering and purifying flue gas from the aluminum ladle and the waste heat of the residual anode, including an aluminum electrolytic cell 1, an aluminum ladle 2, and an ejector 3, and an aluminum suction pipe 4 is arranged between the electrolytic cell 1 and the aluminum ladle 2 , an ejector 3 is provided on the aluminum ladle 2, the ejector exhaust outlet quick joint 19 of the ejector 3 is connected with the ejector exhaust connection pipe 5, and the ejector 3 is connected with the ejector inlet pipe 20, The ejector tail gas connecting pipe 5 is connected to one end of the steel pipe 11 arranged on the aluminum electrolytic cell 1, and the other end of the steel pipe 11 is connected to the smoke exhaust main pipe 17. The lower part of the tank is laid, and a hose 6 is provided between the steel pipe 11 and the ejector exhaust pipe 5, and a new anode preheating box 21 is arranged before the ejector exhaust pipe 5 and the hose 6, and the hose 6 and the st...

Embodiment 2

[0028] On the basis of Example 1, the residual heat of the residual carbon block is used to preheat the new anode carbon block before the carbon block is replaced, and the new anode preheating box can be used alone, and the exhaust gas of the residual electrode and the flue gas of the electrolytic cell are discharged into the Flue gas purification system.

[0029]The new anode preheating box 21 is provided with an air intake pipe 22 in the middle of one side, and a flue gas outlet pipe 23 on the top of the opposite side. The flue gas outlet pipe 23 of the new anode preheating box 21 is connected to the valve one 7 through the quick joint of the air pipe An induced draft fan is arranged in the air pipe between the flue gas outlet pipe 23 and the valve one 7, a new anode preheating box 24 is arranged at the end of the air inlet pipe 22, and a partition 25 is arranged in the new anode preheating box 24 to preheat the new anode The box 24 is divided into a placement chamber 26 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com