Production method for reducing cracks of investment casting CK3MCuN superaustenitic stainless steel

A technology of austenitic stainless steel and investment casting, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., which can solve the problems of poor control of casting structure and weight, failure to quickly pass through the brittle phase temperature zone, and damage To solve problems such as operators and employees, to achieve the effect of increasing penetration pass rate and weldability, no safety hazards, and avoiding delays in delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

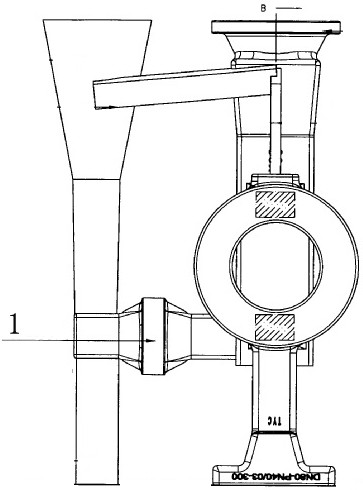

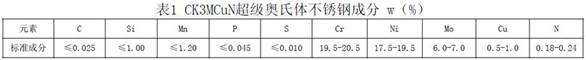

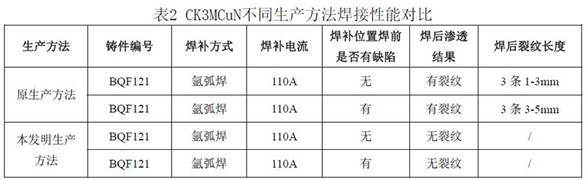

[0019] A customer's butterfly valve casting with product number BQF121, with a unit weight of 3.63kg, requires penetration testing of defects ≤ level 3 according to ASME B 16.34 standards. The original production method: CK3MCuN raw material plus 30% recycled material, top injection pouring system without filter, smelting in atmospheric intermediate frequency furnace. After the penetration test of the casting, there are many 5-10mm long cracks on the surface, especially the cracks at the junction of the flange and the shaft; in addition to crack defects, the casting surface also has slag inclusions and air hole defects, the penetration is unqualified, and the overall quality of the casting is poor. Castings are very sensitive to cracks during welding and repairing. If the grinding temperature is too high, cracks will occur, and the welding line energy w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com