Method for synthesizing sodium ferric manganese phosphate by treating industrial titanium dioxide by-product

A technology of sodium iron manganese phosphate and titanium dioxide, applied in chemical instruments and methods, phosphorus compounds, structural parts, etc., can solve the problems of inability to monitor the content of various metal ions in real time and difficulties in practical application in enterprises, and achieve good economic benefits , The parameters are easy to control, and the effect with low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

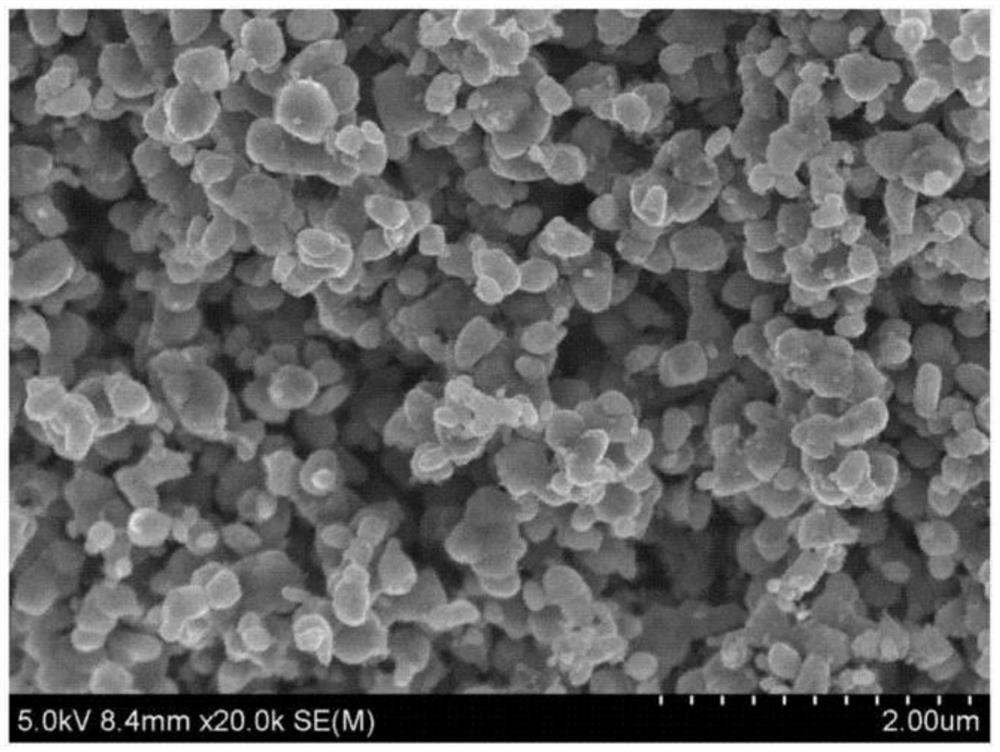

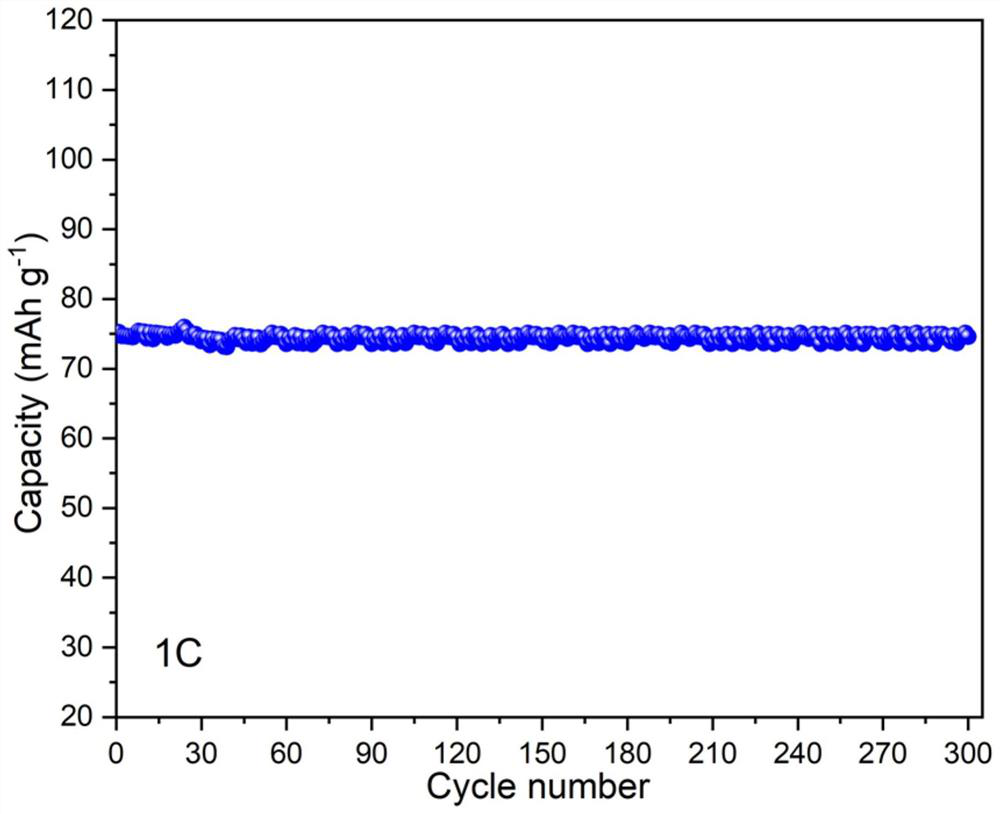

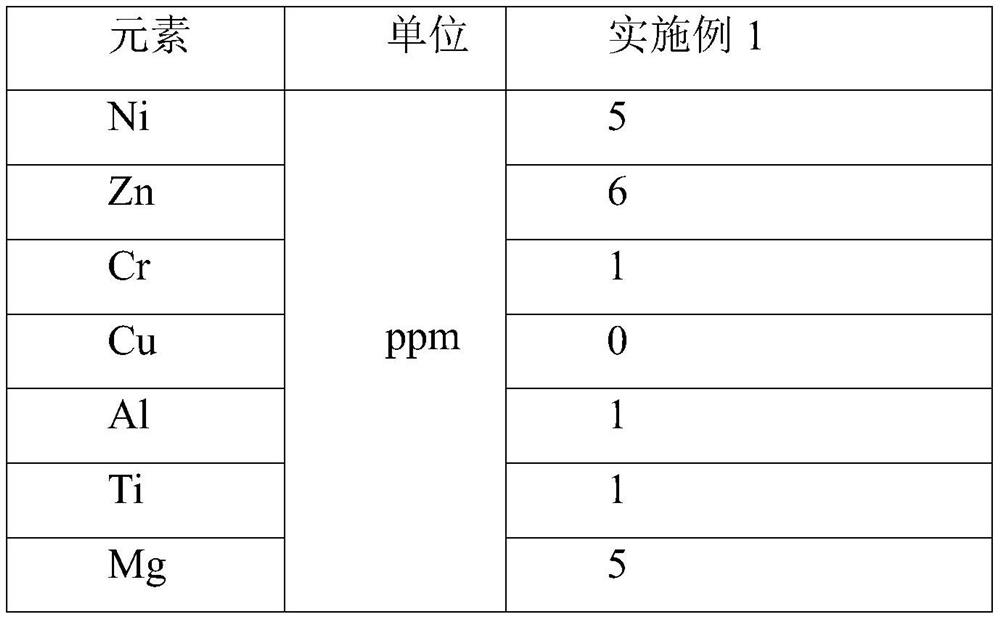

[0024] Embodiment 1 of the present invention is: a method for processing industrial titanium dioxide by-products to synthesize sodium iron manganese phosphate, comprising the following steps:

[0025] (1) Weigh 4000g of by-product ferrous sulfate produced in the process of producing titanium dioxide in a certain factory and prepare it into a solution, add deionized water to dissolve to 10L, and add 10% sodium hydroxide solution in a stirrer with a rotating speed of 40r / min , adjust the pH between 4-5, react for 60 min under the condition that the rotating speed is 40 r / min and the temperature is 25 ℃, and filter to obtain the ferrous sulfate solution for preliminary impurity removal;

[0026] (2) Adjust the pH of the filtrate to be 5-5.5 with a concentration of 10% sodium hydroxide solution, measure the concentration of ferrous sulfate to be 399 g / L, take 1 L of the solution, add 59.9 g of sodium sulfide precipitation solution under water bath stirring conditions For impurity ...

Embodiment 2

[0031] The second embodiment of the present invention is: a method for processing industrial titanium dioxide by-products to synthesize sodium iron manganese phosphate, comprising the following steps:

[0032] (1) Weigh 4000g of by-product ferrous sulfate produced in the process of producing titanium dioxide in a certain factory and prepare it into a solution, add deionized water to dissolve to 10L, and add 10% sodium hydroxide solution in a stirrer with a rotating speed of 40r / min , adjust the pH between 4-5, react for 60min under the condition that the rotating speed is 40r / min and the temperature is 35℃, and filter to obtain the ferrous sulfate solution for preliminary impurity removal;

[0033] (2) Adjust the pH of the filtrate to be 5-5.5 with a concentration of 10% sodium hydroxide solution, measure the concentration of ferrous sulfate to be 399 g / L, take 1 L of the solution, add 59.9 g of sodium sulfide precipitation solution under water bath stirring conditions For impur...

Embodiment 3

[0038] The third embodiment of the present invention is: a method for processing industrial titanium dioxide by-products to synthesize sodium iron manganese phosphate, comprising the following steps:

[0039] (1) Weigh 4000g of by-product ferrous sulfate produced in the process of producing titanium dioxide in a certain factory and prepare it into a solution, add deionized water to dissolve to 10L, and add 10% sodium hydroxide solution in a stirrer with a rotating speed of 40r / min , adjust the pH between 4-5, react for 30min under the condition that the rotating speed is 100r / min and the temperature is 25°C, and filter to obtain the ferrous sulfate solution for preliminary impurity removal;

[0040] (2) Adjust the pH of the filtrate to be 5-5.5 with a concentration of 10% sodium hydroxide solution, measure the concentration of ferrous sulfate to be 399 g / L, take 1 L of the solution, add 59.9 g of sodium sulfide precipitation solution under water bath stirring conditions For im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com