Method for preparing silicon-carbon nano hybrid material by wrapping silicon particles with chloroprene rubber adhesive and lithium ion battery negative electrode

A technology of nano-hybrid materials and hybrid materials, which is applied in the field of preparing silicon-carbon hybrid anode materials, can solve problems that have not been reported, and achieve excellent rate performance and excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing a silicon-carbon nano-hybrid negative electrode material for a lithium-ion battery using silicon nanoparticles and neoprene as raw materials, comprising the following steps:

[0020] (1) Preparation of homogeneous aqueous solution of Si nanoparticles: Si nanoparticles were dispersed in a beaker filled with 30 ml of deionized water, and stirred ultrasonically for 30 min. The silicon nanoparticles were uniformly dispersed in deionized water to obtain solution A.

[0021] (2) Uniform mixing of Si nanoparticles and chloroprene rubber: according to the ratio of Si: chloroprene rubber mass ratio of 1:3, the chloroprene rubber emulsion is added to the A solution, then fully stirred for 30min to make it evenly mixed, Solution B is obtained.

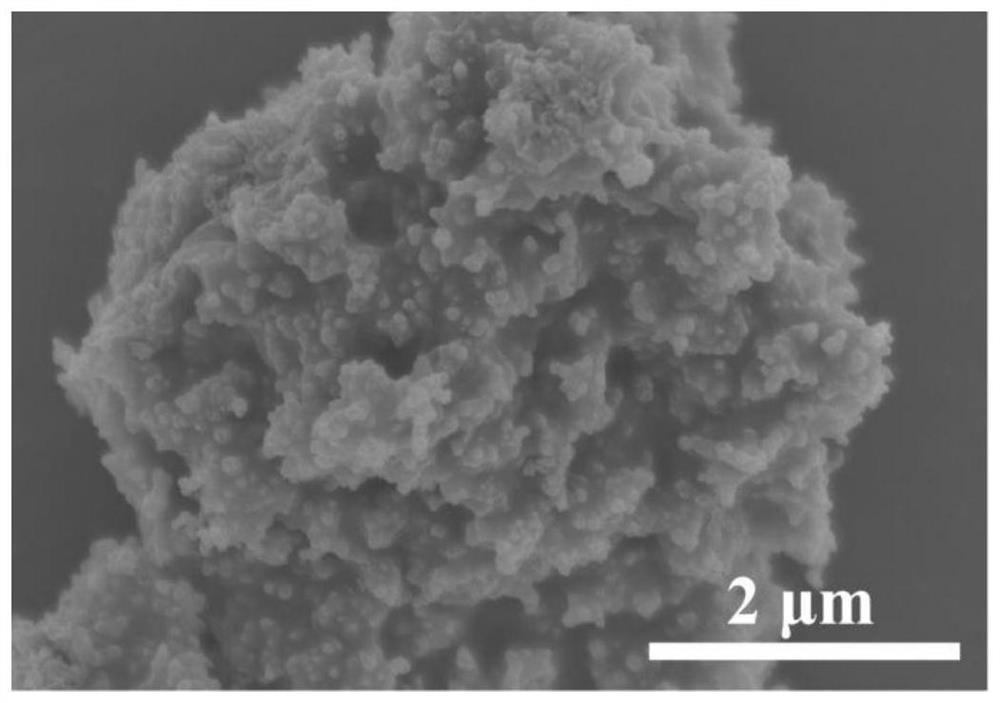

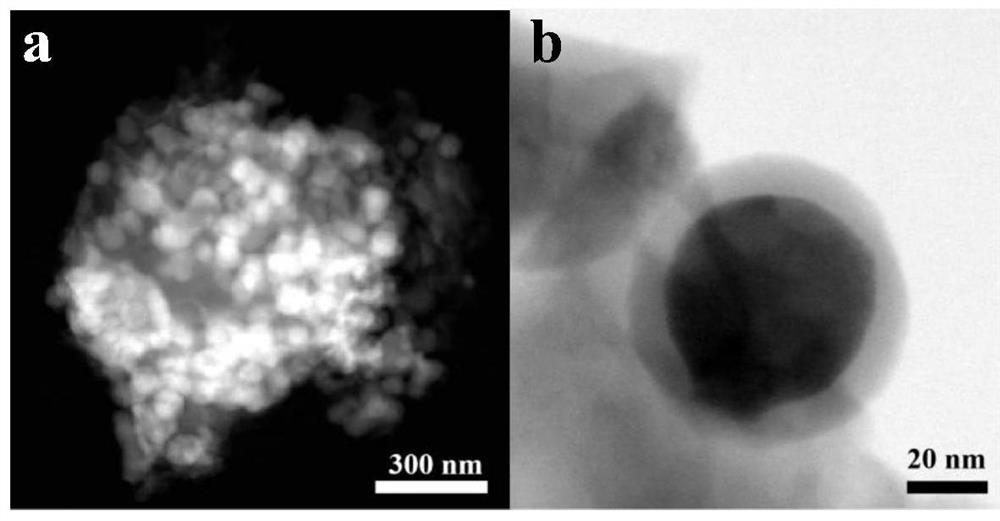

[0022] (3) Preparation of Si@chloroprene rubber precursor: under stirring, quickly add ethanol solution to solution B, and neoprene rapidly precipitates in ethanol, and wraps silicon nanoparticles in it to form Si@c...

Embodiment 2

[0025] A method for preparing a silicon-carbon nano-hybrid negative electrode material for a lithium-ion battery using silicon nanoparticles and neoprene as raw materials, comprising the following steps:

[0026] (1) The preparation of Si nano particle aqueous solution is the same as embodiment 1

[0027] (2) According to the ratio of Si: neoprene mass ratio of 1:1, add neoprene emulsion into solution A, and then fully stir for 30 minutes.

[0028] (3) The preparation of Si@chloroprene rubber precursor is the same as in Example 1

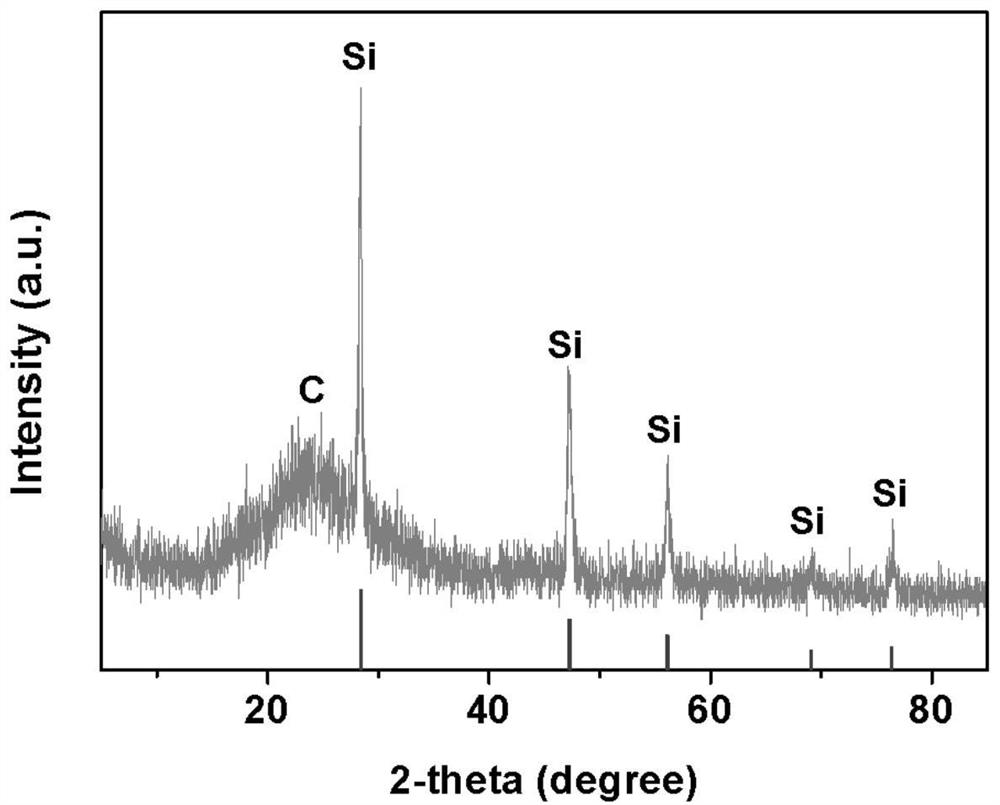

[0029] (4) Calcining Si@chloroprene rubber in a tube furnace to generate the target product Si@SiO2 @C1.

Embodiment 3

[0031] A method for preparing a silicon-carbon nano-hybrid negative electrode material for a lithium-ion battery using silicon nanoparticles and neoprene as raw materials, comprising the following steps:

[0032] (1) The preparation of Si nano particle aqueous solution is the same as embodiment 1

[0033] (2) Add the neoprene emulsion into solution A according to the ratio of Si: neoprene mass ratio of 1:5, and then fully stir for 30 minutes.

[0034] (3) The preparation of Si@chloroprene rubber precursor is the same as in Example 1

[0035] (4) Calcining Si@chloroprene rubber in a tube furnace to generate the target product Si@SiO 2 @C5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com