Deep purification method of glauberite gypsum

A purification method, glauberite technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, calcium/strontium/barium compounds, etc., can solve problems such as limited purification and whitening effect, harsh reaction conditions, complex process, etc. , to achieve the effects of less impurity content, mild process reaction conditions, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

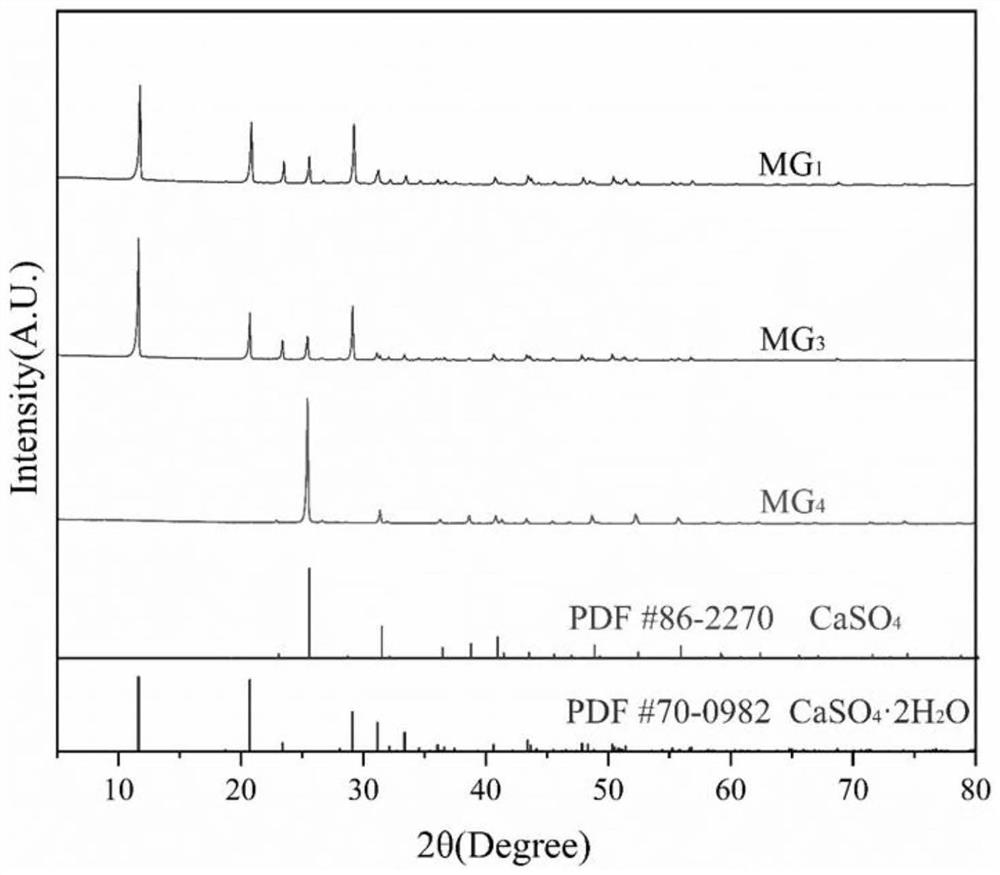

[0044] The effect of sulfuric acid concentration on the removal of impurities was investigated. Take 80g of glauberite gypsum raw material and add it to 400g of 10wt% sulfuric acid solution, heat it in a water bath to 80°C in a 1000mL three-necked flask, control the motor speed to 253rpm, and pickle for 6h. After pickling, stand and filter to obtain the pickled glauberite gypsum, denoted as MG 2 ; Take an appropriate amount of gypsum to measure the chemical composition, and carry out XRD analysis test.

Embodiment 2-3

[0046] With embodiment 1, difference is that sulfuric acid concentration is adjusted to 15wt% and 30wt% respectively, obtains MG 3 and MG 4 .

[0047] The chemical composition of the gypsum of Examples 1-3 is shown in Table 1.

[0048] Table 1 Glauber's salt gypsum raw material and chemical composition (wt%) after pickling with different concentrations of sulfuric acid

[0049]

[0050]

[0051] ND: not detected; LOI: loss on ignition. XRF is a semi-quantitative test method, and the measurement results are kept to decimals

[0052] There is a certain error after the two digits after the point.

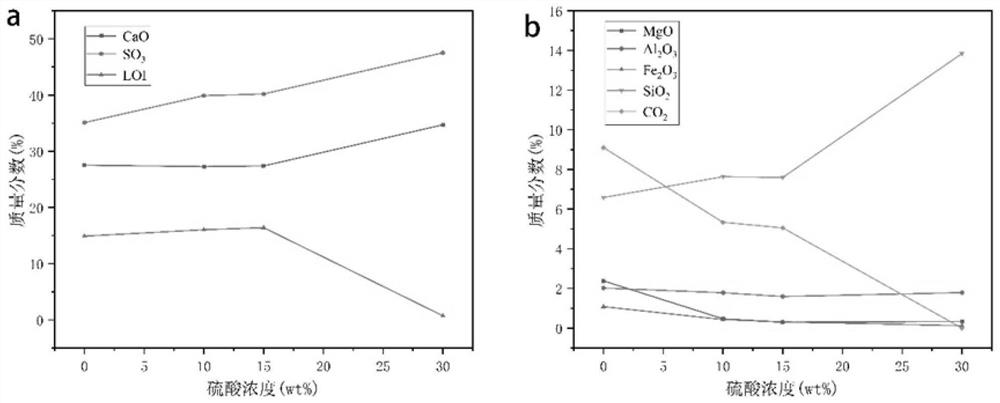

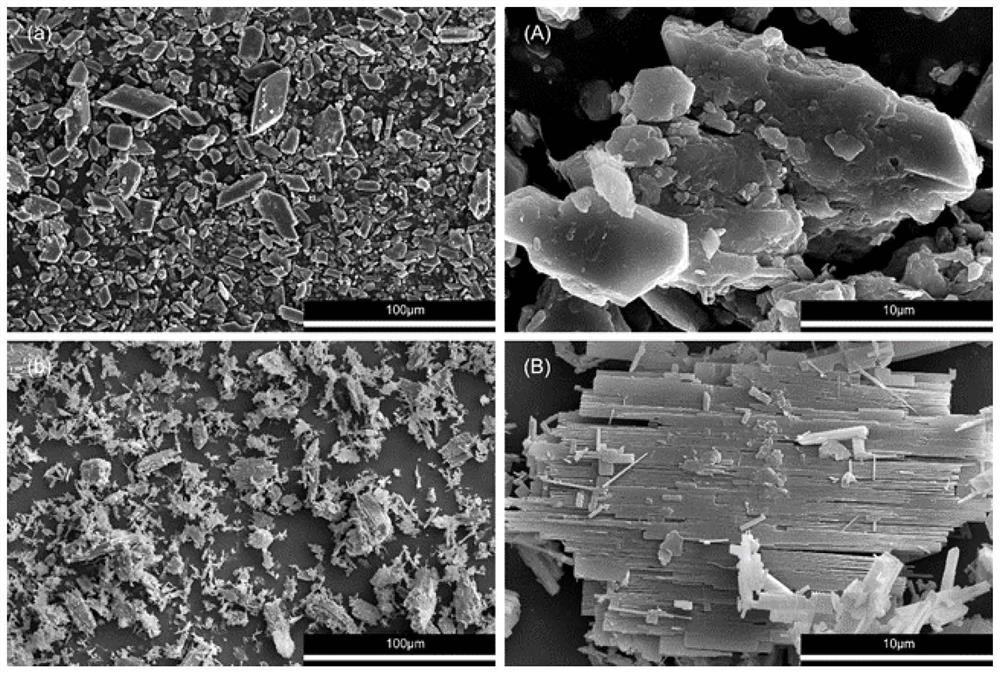

[0053] As shown in Table 1, the content of calcium sulfate dihydrate in glauberite gypsum only accounts for about 70%, and the impurity content is high and the composition is complex. It not only contains metal impurity compounds such as Fe, Al, and Mg, but also contains silicon-based impurities and carbonates. compound. Such as figure 1As shown in b, pickling can effectiv...

Embodiment 4

[0057] The effect of sulfuric acid concentration on the phase state of gypsum was investigated. Take 80g of analytically pure calcium sulfate dihydrate and add it to 400g of 20wt% sulfuric acid solution, heat it to 80°C in a water bath in a 1000mL three-necked flask, control the motor speed to 253rpm, take samples at different time points, and measure the crystal water content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com