Lead zirconate titanate-lead tantalum magnesium niobate piezoelectric ceramic material and preparation method thereof

A technology of lead niobate tantalum magnesium oxide and lead zirconate titanate, applied in the field of piezoelectric ceramic materials, can solve the problems of high dielectric loss, low piezoelectric constant, low mechanical quality factor, etc., achieve low dielectric loss and reduce energy Loss, effect of low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

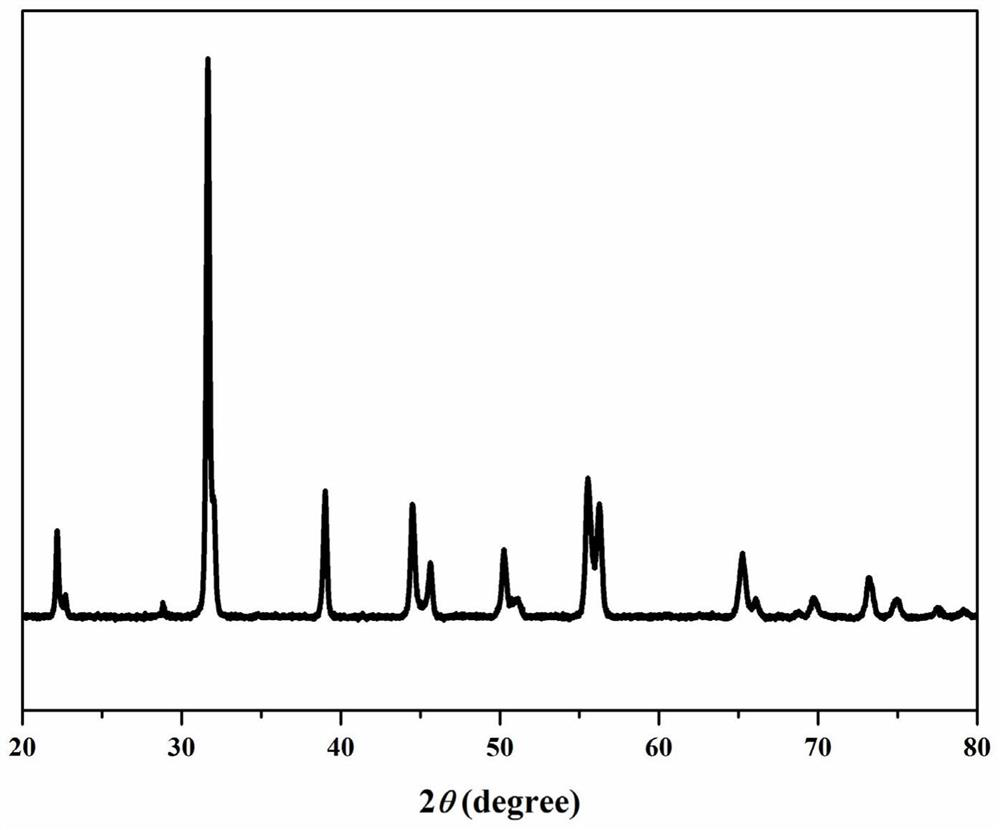

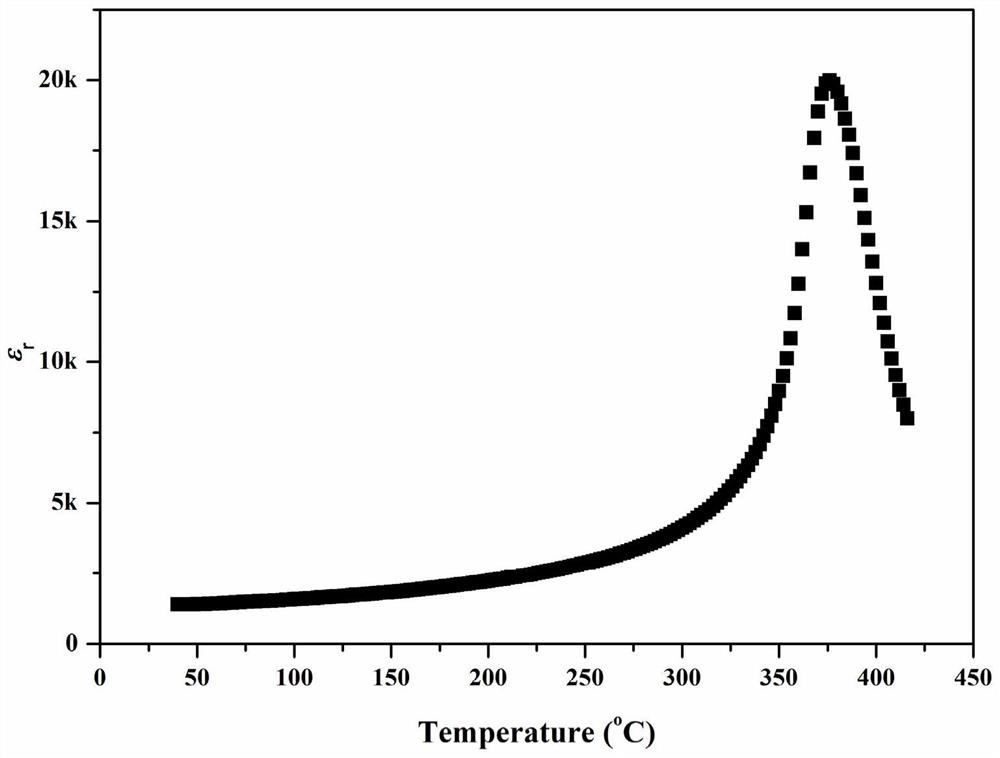

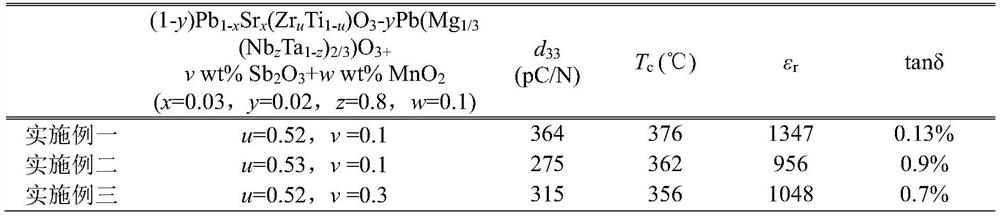

[0024] This example provides a method for preparing a lead zirconate titanate-lead niobate tantalate magnesium piezoelectric ceramic material, which meets the chemical composition of 0.98Pb 0.97 Sr 0.03 (Zr 0.52 Ti 0.48 )O 3 -0.02Pb(Mg 1 / 3 (Nb 0.8 Ta 0.2 ) 2 / 3 )O 3 +0.1wt%Sb 2 o 3 +0.1wt%MnO 2 modified piezoelectric ceramic materials.

[0025] The method described in this embodiment includes the following steps:

[0026] S1, ball milling, weigh the analytically pure raw material SrCO according to the above metering ratio 3 , ZrO 2 、TiO 2 , Sb 2 o 3 , MgO, Pb 3 0 4 , Nb 2 o 5 、 Ta 2 o 5 and MnO 2 Mix it in absolute ethanol, put it into a ball mill tank and use zirconia balls to roll and grind for 30 hours to obtain ball mill material.

[0027] S2, secondary ball milling, drying the absolute ethanol in the ball mill, and pre-sintering the dried powder at 800° C. for 3 hours to obtain pre-sintered powder. Secondary ball milling of pre-sintered powder for ...

Embodiment 2

[0032] This example provides a method for preparing a lead zirconate titanate-lead niobate tantalate magnesium piezoelectric ceramic material, which meets the chemical composition of 0.98Pb 0.97 Sr 0.03 (Zr 0.53 Ti 0.47 )O 3 -0.02Pb(Mg 1 / 3 (Nb 0.8 Ta 0.2 ) 2 / 3 )O 3 +0.1wt%Sb 2 o 3 +0.1wt%MnO 2 modified piezoelectric ceramic materials.

[0033] The method described in this embodiment includes the following steps:

[0034] S1, ball milling, weigh the analytically pure raw material SrCO according to the above metering ratio 3 , ZrO 2 、TiO 2 , Sb 2 o 3, MgO, Pb 3 0 4 , Nb 2 o 5 、 Ta 2 o 5 and MnO 2 Mix it in absolute ethanol, put it into a ball mill tank and use zirconia balls to roll and grind for 18 hours to obtain ball mill material.

[0035] S2, secondary ball milling, drying the absolute ethanol in the ball mill, and keeping the dried powder at 950° C. for 1 hour for pre-sintering to obtain pre-sintered powder. Secondary ball milling of pre-sintered p...

Embodiment 3

[0040] This example provides a method for preparing a lead zirconate titanate-lead niobate tantalate magnesium piezoelectric ceramic material, which meets the chemical composition of 0.98Pb 0.97 Sr 0.03 (Zr 0.52 Ti 0.48 )O 3 -0.02Pb(Mg 1 / 3 (Nb 0.8 Ta 0.2 ) 2 / 3 )O 3 +0.3wt%Sb 2 o 3 +0.1wt%MnO 2 modified piezoelectric ceramic materials.

[0041] The method described in this embodiment includes the following steps:

[0042] S1, ball milling, weigh the analytically pure raw material SrCO according to the above metering ratio 3 , ZrO 2 、TiO 2 , Sb 2 o 3 , MgO, Pb 3 0 4 , Nb 2 o 5 、 Ta 2 o 5 and MnO 2 Mix it in absolute ethanol, put it into a ball mill tank and use zirconia balls to roll and grind for 30 hours to obtain ball mill material.

[0043] S2, secondary ball milling, drying the absolute ethanol in the ball mill, and keeping the dried powder at 950° C. for 1 hour for pre-sintering to obtain pre-sintered powder. Secondary ball milling of pre-sintered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com