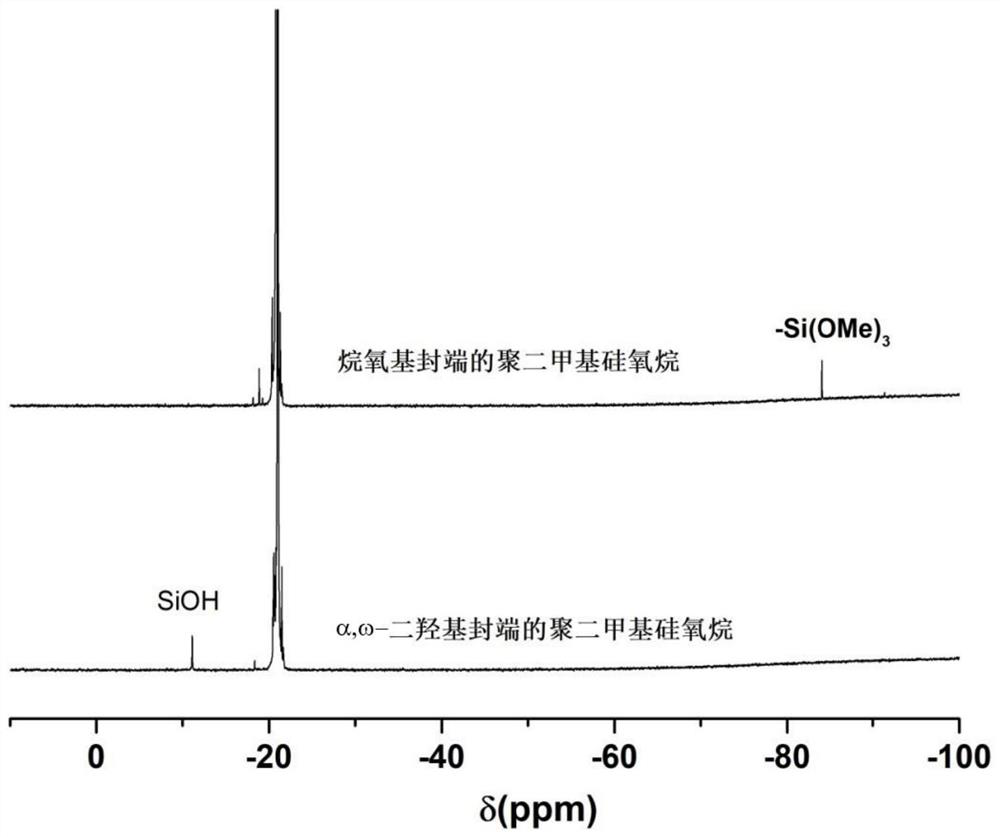

Preparation method of alkoxy-terminated linear polydimethylsiloxane

The technology of polydimethylsiloxane and dimethylsiloxane is applied in the field of preparation of linear polydimethylsiloxane, which can solve the difficulty in the reaction between siloxy groups and silanol groups, prolong the reaction time, and increase the reaction time. Process and other problems, to achieve the effect of controllable viscosity range, simple production process and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

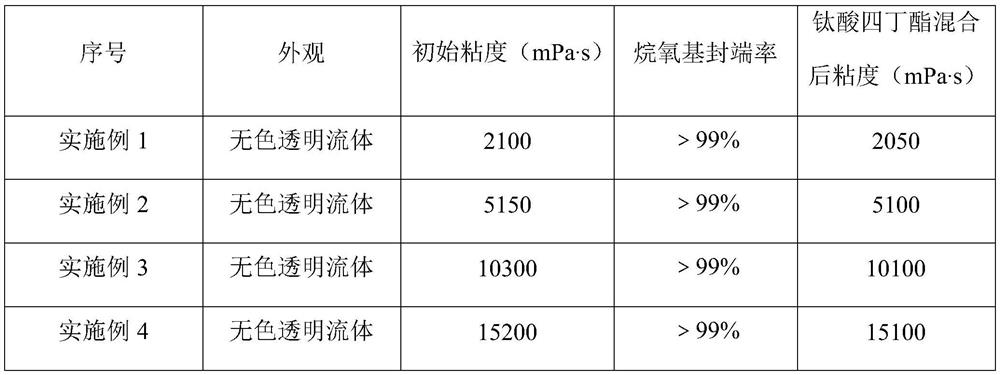

Embodiment 1

[0032] Add 60kg of α, ω-dihydroxyl-terminated polydimethylsiloxane, 1.8kg of tetramethoxysilane, 16g of formic acid, and 48g of sodium acetate at 2000mPa·s respectively in a 100L mechanical reaction kettle. After stirring evenly, the reaction The temperature of the kettle was raised to 40°C. After 120 minutes of reaction, the vacuum degree was controlled at -0.06MPa. After evacuating for 100 minutes, alkoxy-terminated polydimethylsiloxane was obtained. The product performance test results are shown in Table 1.

Embodiment 2

[0034] Add 60kg of α, ω-dihydroxyl-terminated polydimethylsiloxane, 1.5kg of vinyltrimethoxysilane, 60g of acetic acid, and 60g of sodium carbonate at 5000mPa·s into a 100L mechanical reactor, and stir evenly. The temperature of the reactor was raised to 60°C. After 80 minutes of reaction, the vacuum degree was controlled at -0.06MPa. After 80 minutes of vacuuming, alkoxy-terminated polydimethylsiloxane was obtained. The product performance test results are shown in Table 1. .

Embodiment 3

[0036] In a 100L mechanical reactor, add 10000mPa·s of α, ω-dihydroxy-terminated polydimethylsiloxane 60kg, methyltrimethoxysilane 980g, acetic anhydride 140g, sodium carbonate 30g, sodium acetate 40g, After stirring evenly, the temperature of the reactor was raised to 80°C. After 60 minutes of reaction, the vacuum degree was controlled at -0.08MPa. After 60 minutes of vacuuming, alkoxy-terminated polydimethylsiloxane was obtained. Product performance test results See Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com