Preparation method of metal titanium particle reinforced magnesium-based composite material

A particle-reinforced, composite material technology, applied in the field of magnesium-based composite materials, can solve the problems of combustion, uneven dispersion of titanium particles, easy oxidation, etc., to achieve high strength and plasticity, improve mechanical properties, and improve the effect of plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

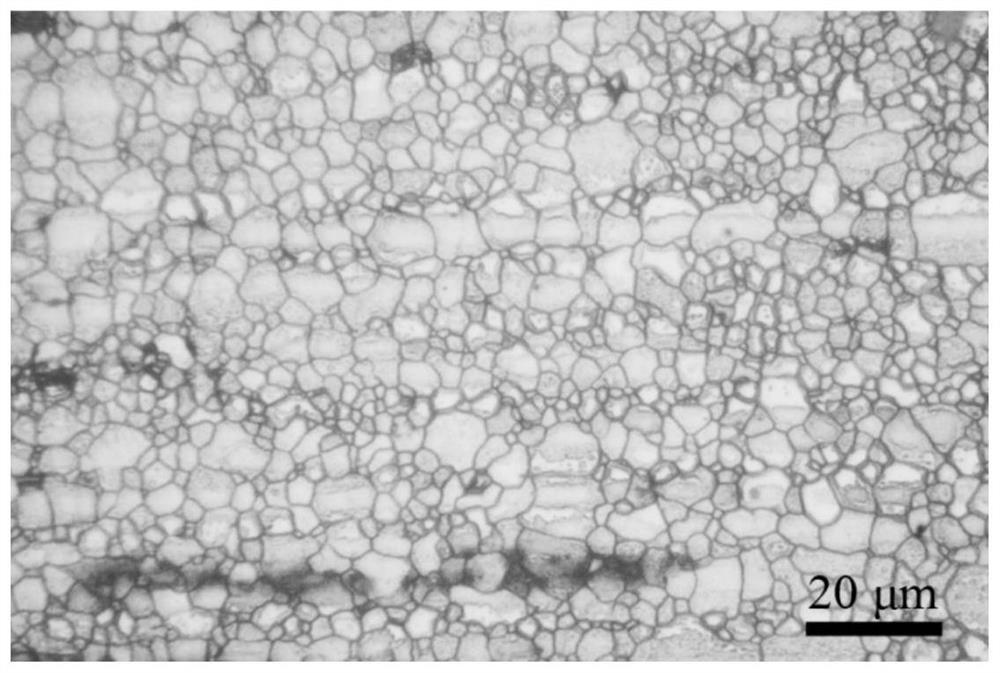

Embodiment 1

[0030] A method for preparing a titanium particle reinforced magnesium-based composite material, the specific preparation method comprising the following steps:

[0031] (1) Preparation of titanium particle preform: Weigh 1g of titanium particles with an average particle size of 80nm and 4g of magnesium chips with an average particle size of 75μm, put them into a stainless steel ball mill jar, add 25g of stainless steel balls, repeatedly evacuate and then flush with argon for 3 After the second time, under the protection of argon, the ball milled for 90 minutes, the ball milling speed was 80rmp, and the mixed powder of titanium particles and magnesium chips was obtained by sieving after ball milling. body;

[0032] (2) Stirring casting molding: SF at a volume ratio of 1:99 6 and CO 2 Under gas protection, put 995g of AZ31B magnesium alloy ingot into the crucible to melt, then add 5g of titanium particle prefabricated body obtained in step (1) into the magnesium melt and keep...

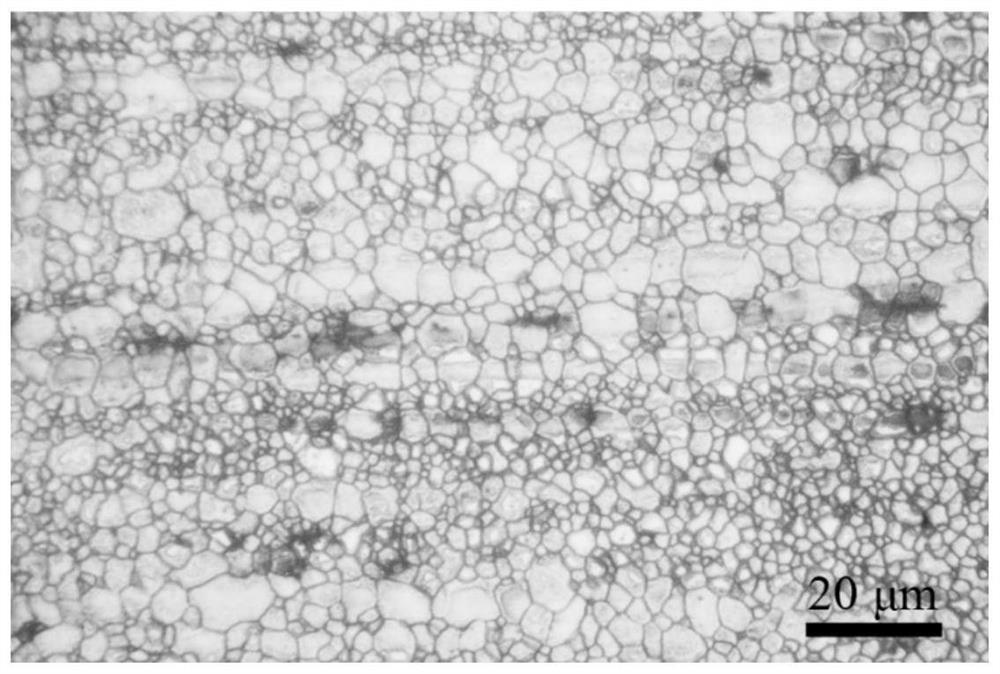

Embodiment 2

[0035] A method for preparing a titanium particle reinforced magnesium-based composite material, the specific preparation method comprising the following steps:

[0036] (1) Preparation of titanium particle preform: Weigh 2g of titanium particles with an average particle size of 80nm and 8g of magnesium chips with an average particle size of 75μm, put them into a stainless steel ball mill jar, add 50g of stainless steel balls, repeatedly evacuate and then flush with argon for 3 After the second time, under the protection of argon, the ball milled for 90 minutes, the ball milling speed was 80rmp, and the mixed powder of titanium particles and magnesium chips was obtained by sieving after ball milling. body;

[0037] (2) Stirring casting molding: SF at a volume ratio of 1:99 6 and CO 2 Under the protection of gas, put 990g of AZ31B magnesium alloy ingot into the crucible to melt, then add 10g of titanium particle preform obtained in step (1) into the magnesium melt and keep it...

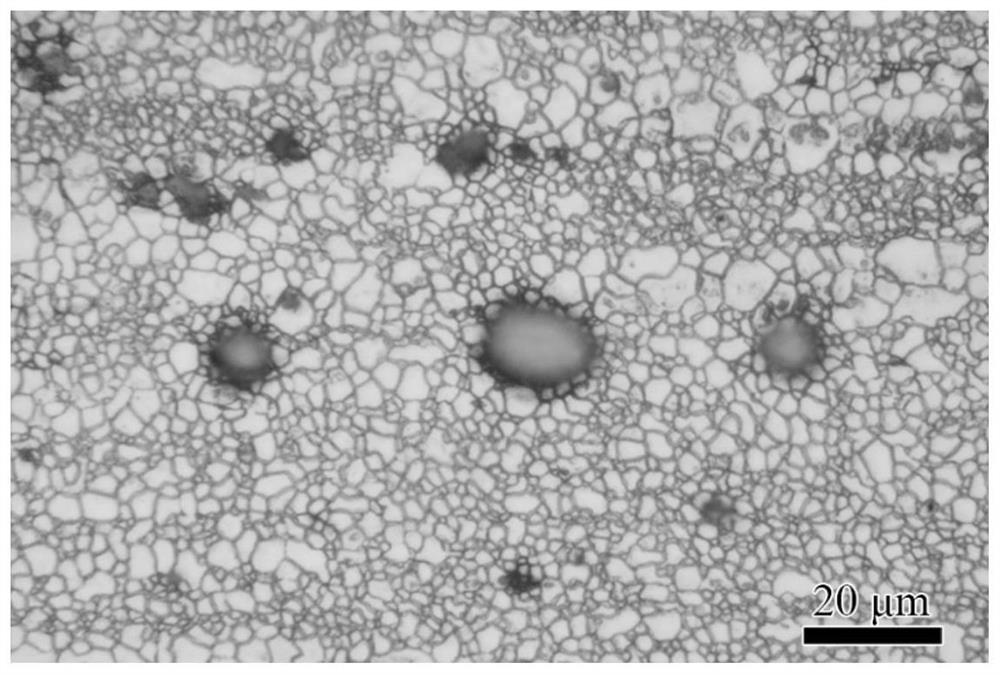

Embodiment 3

[0040] A method for preparing a titanium particle reinforced magnesium-based composite material, the specific preparation method comprising the following steps:

[0041](1) Lamination preparation of titanium particles coated with aluminum foil: Weigh 30g of titanium particles with an average particle size of 8 μm, lay them flat on an aluminum foil with a width of 250 mm, and roll the aluminum foil with a single width of 5 mm along one side of the aluminum foil, and finally roll it into a long Strip and lightly press out the air to obtain a laminate of titanium particles wrapped in aluminum foil;

[0042] (2) Stirring casting molding: SF at a volume ratio of 1:99 6 and CO 2 Under the protection of gas, put 970g of AZ31B magnesium alloy ingot into the crucible to melt, then add the aluminum foil-coated titanium particles containing 30g of titanium particles obtained in step (1) into the magnesium melt at 630°C, and keep it warm for 10min After cooling down to 630°C to form a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com