Spinning nozzle assembly, multi-cavity hollow fiber tube, preparation method of multi-cavity hollow fiber tube and medical instrument

A medical device and spinneret technology, which is applied in fiber processing, filament/thread forming, textile and papermaking, etc., can solve the problems of circular radial cross-section of the inner lumen of multi-cavity hollow fiber tubes, etc., and achieve the effect of reducing the pushing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing a multi-lumen hollow fiber tube, comprising the following steps:

[0047] S11: Send the polymer raw material particles into the screw with heater.

[0048] S12: The polymer raw material particles are heated in the screw to become a polymer liquid;

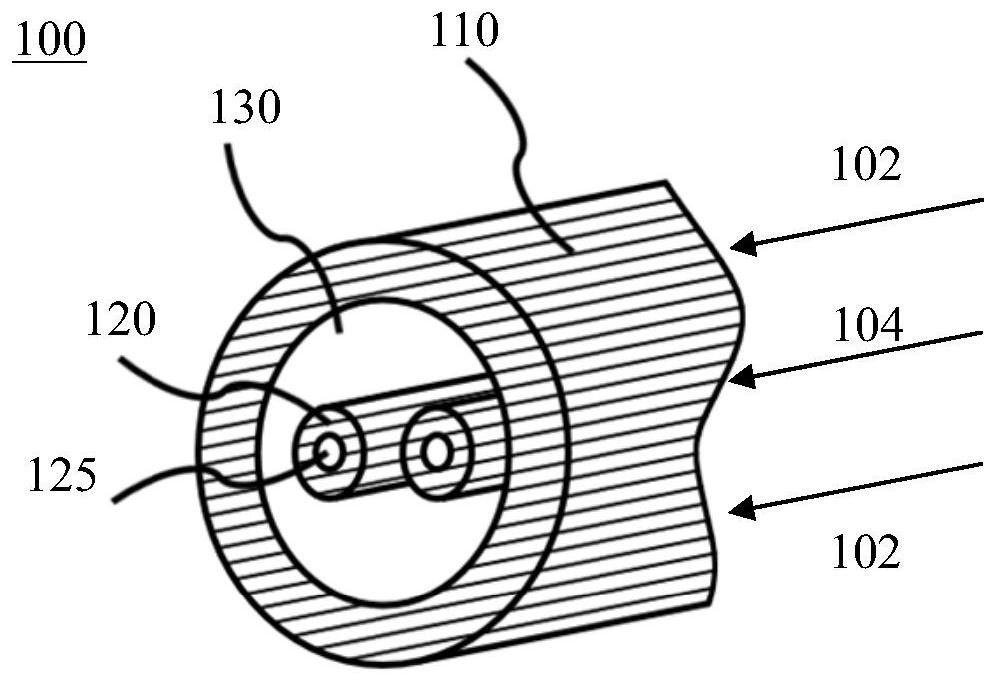

[0049] S13: The polymer liquid enters with the rotation of the screw image 3 Flow passage 130 of spinneret assembly 100 is shown.

[0050] S14: The polymer liquid leaves the spinneret assembly 100 from the outlet of the flow channel 130 after flowing through the flow channel 130;

[0051] S15: The polymer liquid leaving the outlet of the flow channel is cooled and shaped to obtain the multi-lumen hollow fiber tube.

[0052] Optionally, before the polymer liquid enters the spinneret assembly 100, it passes through a filter as the screw rotates, and the function of the filter is to filter out insoluble particles in the polymer liquid.

[0053] Optionally, the poly...

Embodiment 1

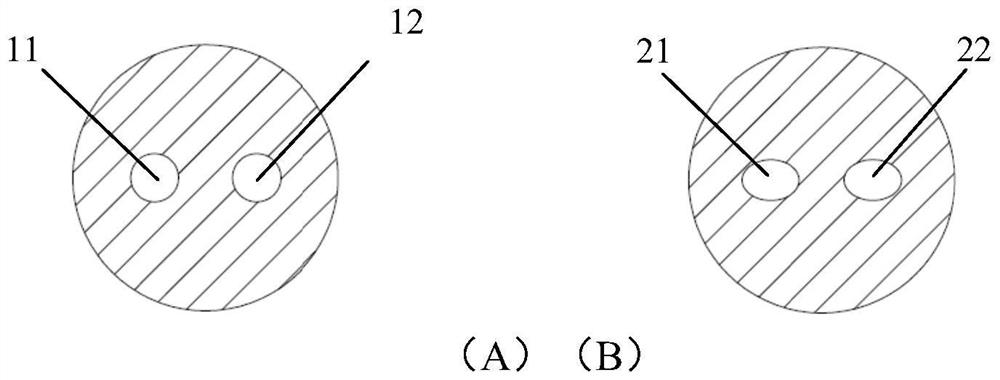

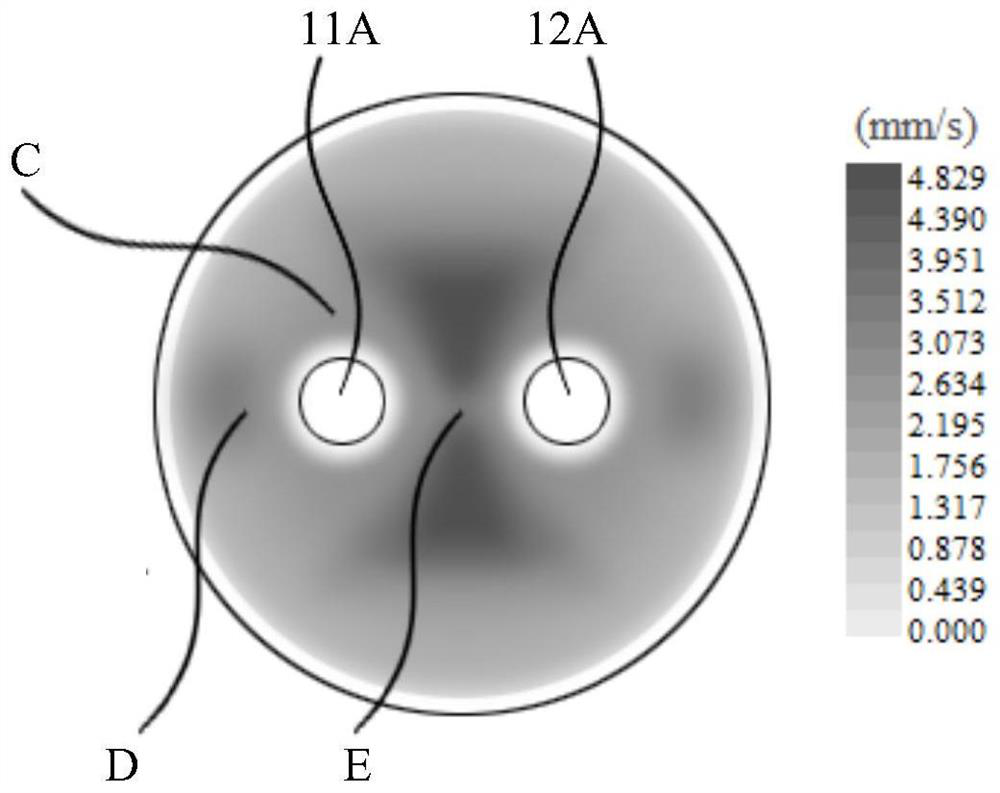

[0067] use image 3 The shown spinneret assembly 100 has an elliptical air hole needle 120 with a ratio of the minor axis to the major axis of 0.71. The double-cavity hollow fiber tube is made of nylon, and the temperature inside the spinneret assembly 100 is 250°C. Stomach needles 120 are fed with the same air pressure, and the inner diameters of the two circular cavities of the prepared multi-lumen hollow fiber tube are both 0.144mm, and the ellipticities are respectively 0.0004" and 0.0003". Figure 5 shown. The prepared multi-lumen hollow fiber tube is applied in a peripheral central venous catheter, a guide wire is passed into one cavity, and a medical solution is passed into the other cavity.

Embodiment 2

[0069] use image 3 The shown spinneret assembly 100 has an elliptical air hole needle 120 with a ratio of the minor axis to the major axis of 0.65. Polyurethane is used as a raw material to make a three-cavity hollow fiber tube. The temperature inside the spinneret assembly 100 is 165° C. The extreme difference in air pressure between the stomatal needles 120 is 5inH 2 0, the internal diameters of three circular cavities of the multi-cavity hollow fiber tube made are respectively 0.212mm, 0.171mm, 0.208mm, and the ellipticity is respectively 0.0004", 0.0003", 0.0004", such as Figure 6 shown. The so-called extremely poor inflation pressure refers to the value of the air pressure in the stomata needle with the largest inflation pressure minus the air pressure in the stomata needle with the smallest inflation pressure among the three stomata needles. The prepared multi-lumen hollow fiber tube is applied in a physiological radiofrequency ablation catheter, two larger cavities ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com